Method for preparing ZnO@ZIF-8 compound, ZnO@ZIF-8 compound and gas sensor

A gas-sensing sensor and compound technology, applied in instruments, scientific instruments, coatings, etc., can solve the problems of poor stability, low sensitivity, easy poisoning, etc., and achieve the effect of improving gas selectivity, stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

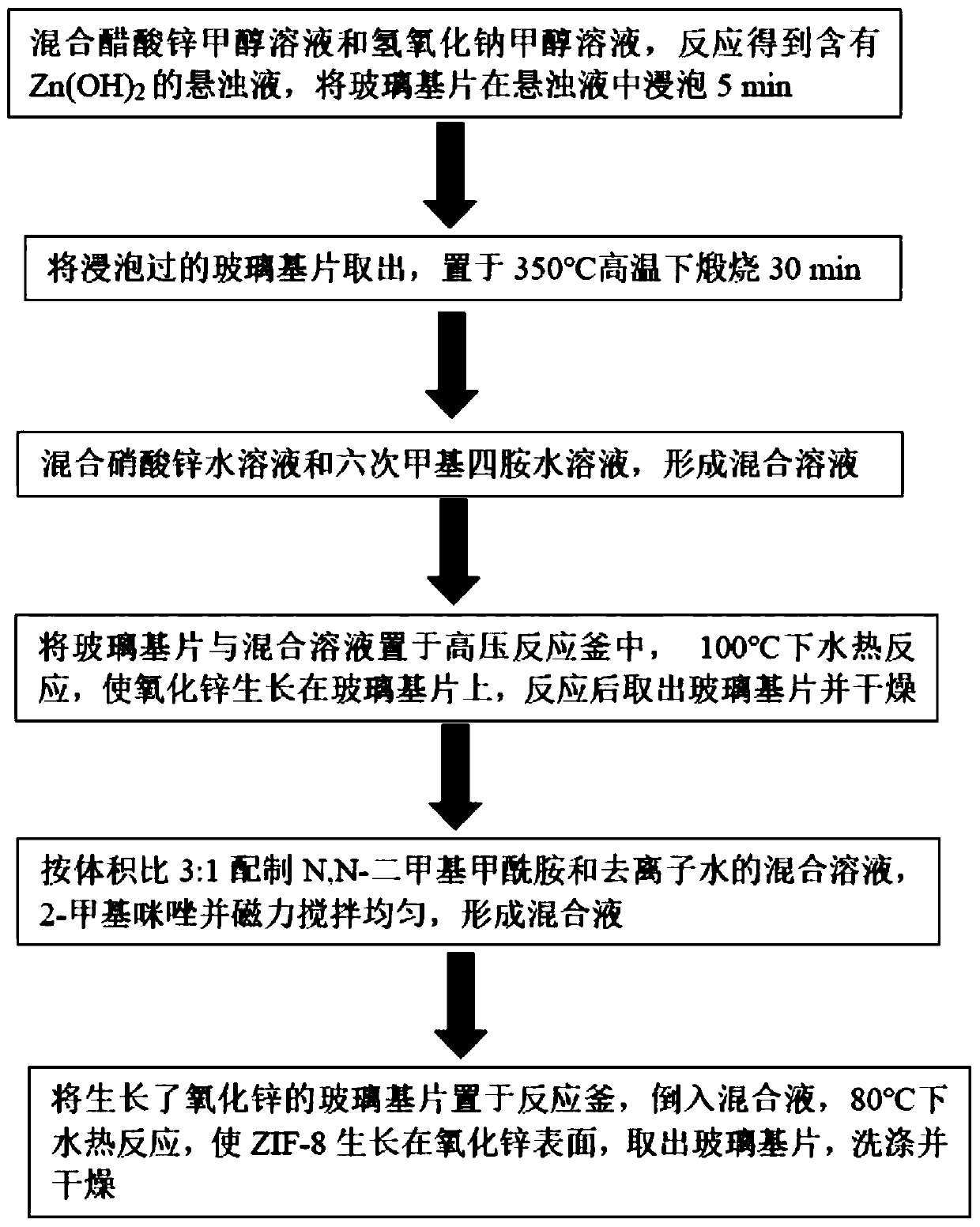

[0031] Example 1: Preparation of ZnO@ZIF-8 complex

[0032] The following chemical reagents used were purchased from the market: zinc acetate dihydrate (ZnAc 2 2H 2 O); zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O); methanol; sodium hydroxide (NaOH); hexamethylenetetramine (HMTA); N,N-dimethylformamide (DMF); 2-methylimidazole; absolute ethanol; deionized water.

[0033] The specific process of preparing ZnO@ZIF-8 complex is as follows.

[0034] First, prepare zinc acetate in methanol and sodium hydroxide in methanol. Weigh 0.24g zinc acetate dihydrate (ZnAc 2 2H 2 (0) and 0.43g sodium hydroxide (NaOH), were dissolved in 10ml of absolute methanol respectively, placed on a magnetic stirrer for magnetic stirring for 10min, then NaOH was slowly poured into the ZnAc 2 2H 2 In the O solution, the final product containing Zn(OH) 2 of the suspension.

[0035] Next, the glass substrate with a size of 2cm×2cm was placed in absolute ethanol and deionized water for 5min, ultr...

Embodiment 2

[0042] Example 2: Gas selectivity of ZnO@ZIF-8 composite

[0043] The final product prepared in Example 1—the ZnO@ZIF-8 complex was used to prepare the sensor.

[0044] Feed 50ppm of CO and H into the sensor respectively 2 、CH 4 、C 2 h 6 、C 2 h 4 、C 2 h 2 Gas, measure its sensitivity value Ra / Rg, where Ra is the resistance before ventilation, and Rg is the resistance after gas is passed).

[0045] The result is as Image 6 shown. As shown in the figure, the ZnO@ZIF-8 complex is 2 especially sensitive, while H 2 It is one of the dissolved fault characteristic gases in power transformer oil, so this ZnO@ZIF-8 composite can be used for the detection of dissolved fault characteristic gases in transformer oil.

Embodiment 3

[0046] Example 3: ZnO@ZIF-8 complex on H 2 sensitive stability

[0047] The intermediate product (i.e., ZnO core) and the final product (i.e., ZnO@ZIF-8 complex) of Example 1 were prepared into sensors respectively, and these two sensors were detected on the gas sensing test platform against 50ppm H 2 Sensitivity value of , detected every 5 days.

[0048] The result is as Figure 7 As shown, the sensor prepared using the ZnO@ZIF-8 composite maintained a good resistance to H over a 30-day test period. 2 Sensitive stability, while the sensor made of pure ZnO material is sensitive to H 2 The sensitivity decreased significantly with the increase of time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com