Fluid Universal Compliant and Force Sensing Hands for Robots

A technology of sensing palm and pressure sensor, applied in the field of fluid universal compliance and force sensing palm for robots, can solve the problems of high stiffness buffer, damping effect, poor spring working state and weak buffer capacity, etc. Matching problems, increasing adaptability, reducing system cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

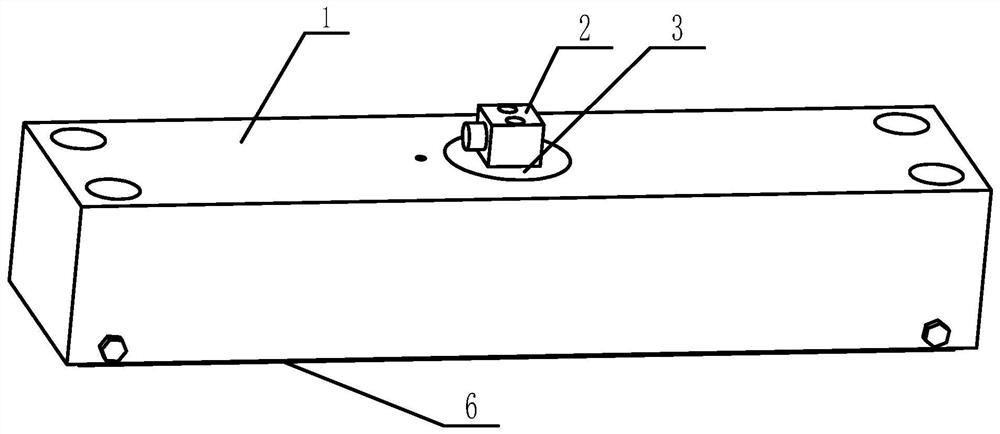

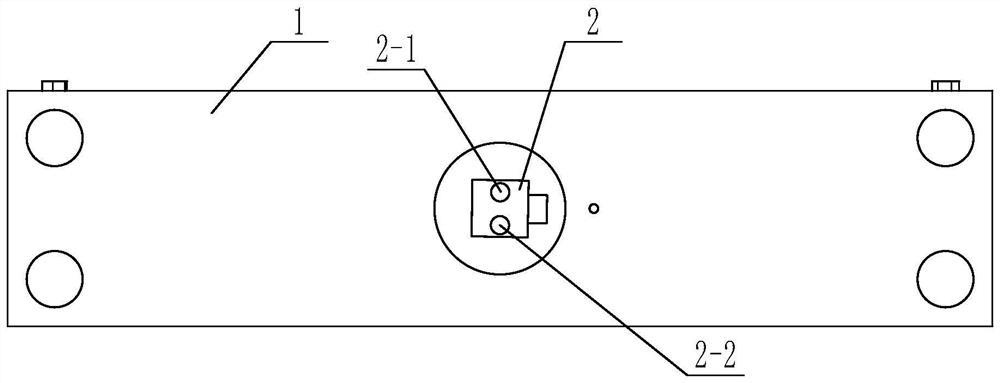

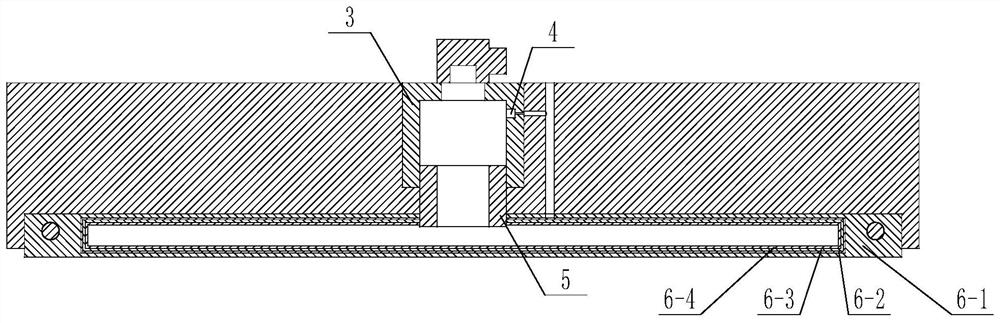

[0018] Such as figure 1 , 2 As shown, a fluid universal compliance and force sensing palm for a robot includes a housing 1, a solenoid valve 2, a control chamber 3, a pressure sensor 4, a temperature sensor, and a sensing palm unit 6. The housing 1 It is rectangular, and a control cavity 3 is installed in the housing 1, and a sensing palm unit 6 is installed on the bottom surface of the housing 1. The upper end of the control cavity 3 is connected with the solenoid valve 2, and the lower end of the control cavity 3 passes through the The pipe 5 is connected to the sensing palm unit 6, and the pressure sensor 4 is located on the inner wall of the control chamber 3. The sensing palm unit 6 includes an outer rubber layer 6-1, a strain sensing layer 6-2, and a metal reinforcement layer 6-3 and the inner rubber layer 6-4, the metal reinforcement layer 6-3 and the strain sensing layer 6-2 are bonded together, and sandwiched between the inner rubber layer 6-4 and the outer rubber la...

Embodiment 2

[0020] Such as Figure 4-5 As shown, a fluid universal compliance and force sensing palm for a robot includes a housing 1, a solenoid valve 2, a control chamber 3, a pressure sensor 4, a temperature sensor, and a sensing palm unit 6. The housing 1 It is a hollow cylinder, and a control chamber 3 is installed in the housing 1, and a sensing palm unit 6 is installed on the side of the housing 1. The upper end of the control chamber 3 is connected with the solenoid valve 2, and the lower end of the control chamber 3 The pressure sensor 4 is located on the inner wall of the control cavity 3 through its inner pipe 5 and connected to the sensing palm unit 6. The sensing palm unit 6 includes an outer rubber layer 6-1, a strain sensing layer 6-2, and a metal reinforcement layer. 6-3 and the inner rubber layer 6-4, after the metal reinforcement layer 6-3 and the strain sensing layer 6-2 are pasted together, they are sandwiched between the inner rubber layer 6-4 and the outer rubber lay...

Embodiment 3

[0022] Such as Figure 6-7As shown, a fluid universal compliance and force sensing palm for a robot includes a solenoid valve 2, a control cavity 3, a pressure sensor 4, a temperature sensor, and a sensing palm unit 6. The sensing palm unit is spherical, The upper end of the control cavity 3 is connected to the solenoid valve 2, the lower end of the control cavity 3 is connected to the sensor palm unit 6 through the inner pipeline 5, the pressure sensor 4 is located on the inner wall of the control cavity 3, and the sensor The palm unit 6 includes an outer rubber layer 6-1, a strain sensing layer 6-2, a metal reinforcement layer 6-3 and an inner rubber layer 6-4. After the metal reinforcement layer 6-3 and the strain sensing layer 6-2 are bonded together , sandwiched between the inner rubber layer 6-4 and the outer rubber layer 6-1, the cavity of the sensing palm unit 6 is filled with a certain amount of liquid, the strain sensing layer 6-2 is equipped with a temperature senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com