Multi-functional cut-off machine having manual and full-automatic working modes

A working mode, cutting machine technology, applied in the control of workpiece feed movement, manufacturing tools, grinding feed movement, etc., can solve problems such as difficulty in fault diagnosis and elimination, inconvenient work and maintenance, and large size of the cutter, To achieve the effect of simple structure, labor-saving and convenient work, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

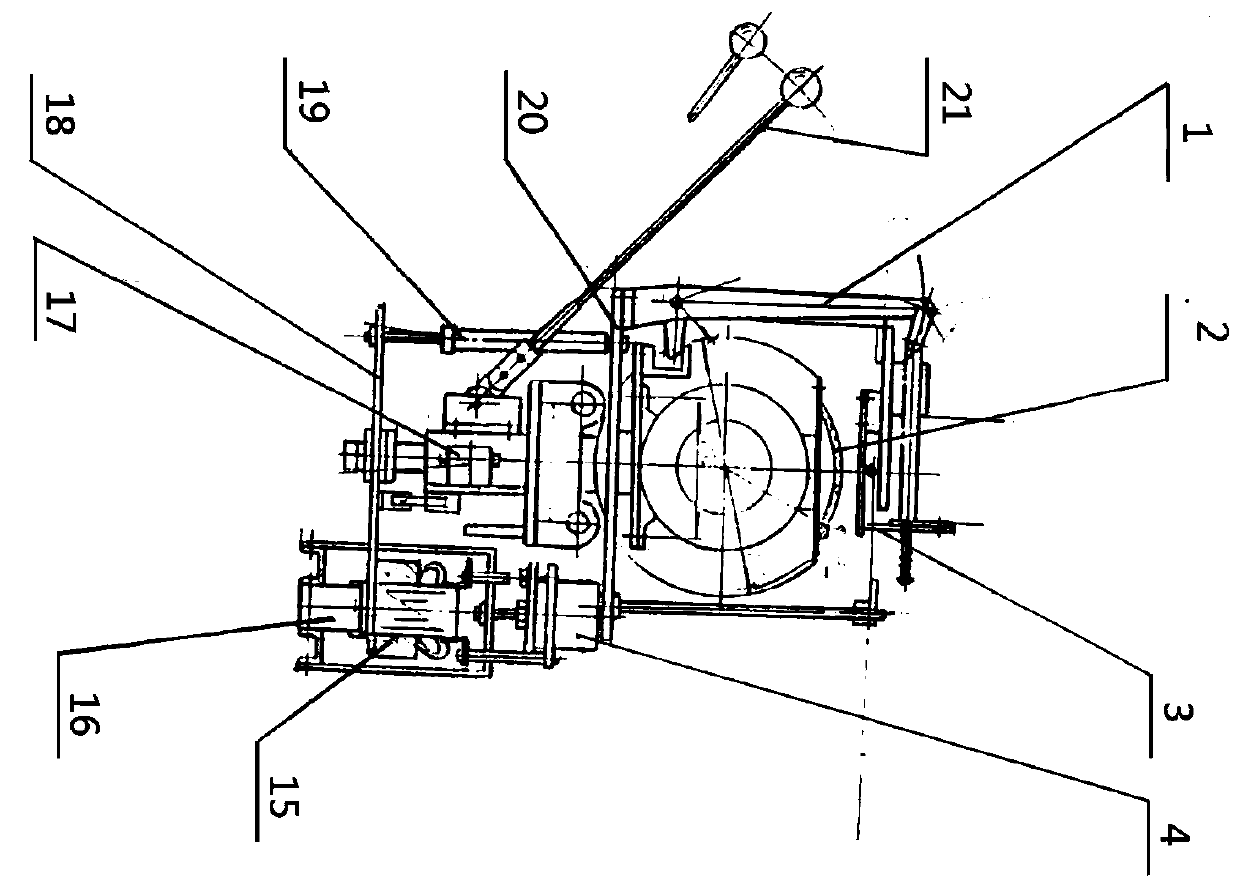

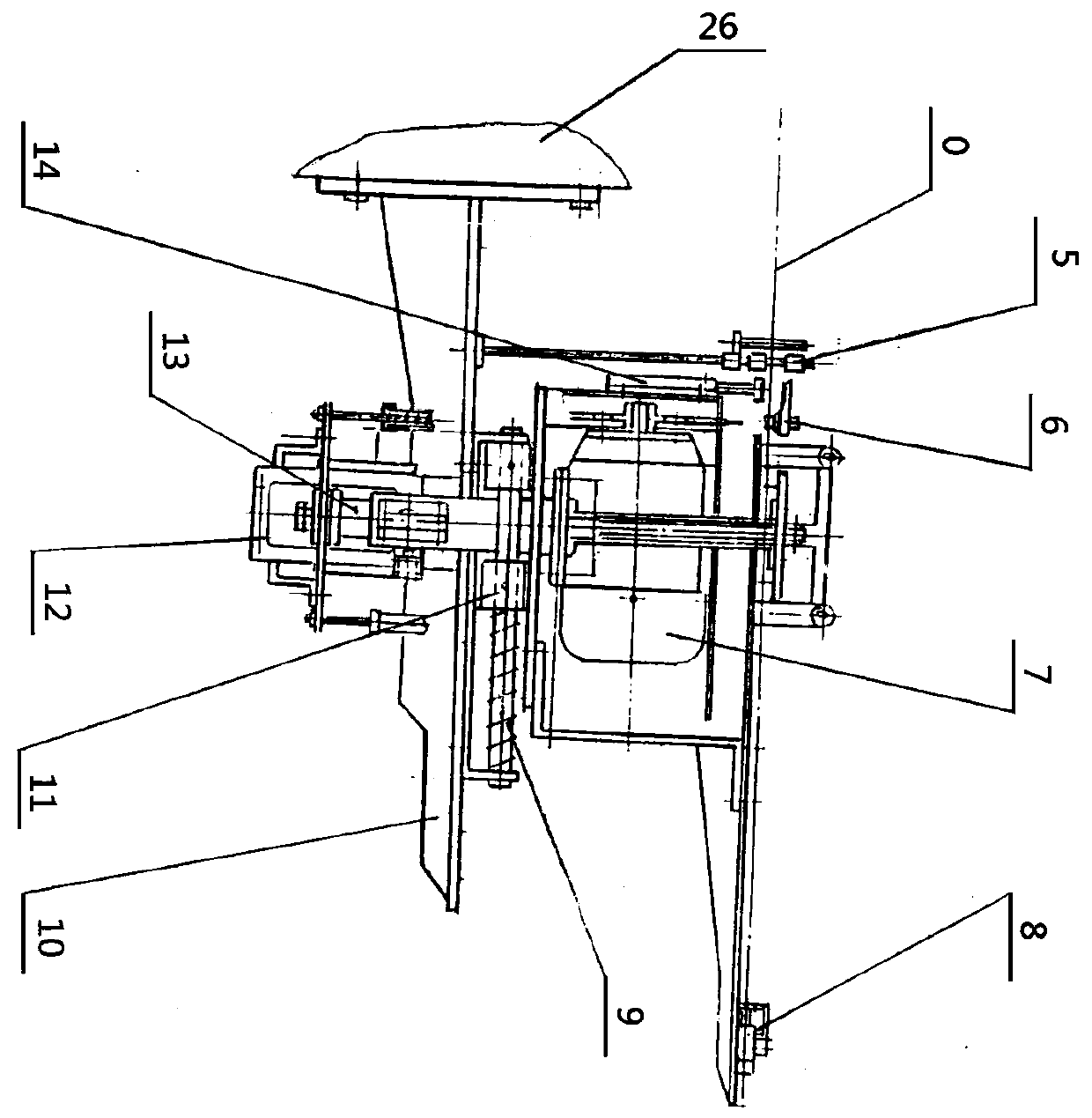

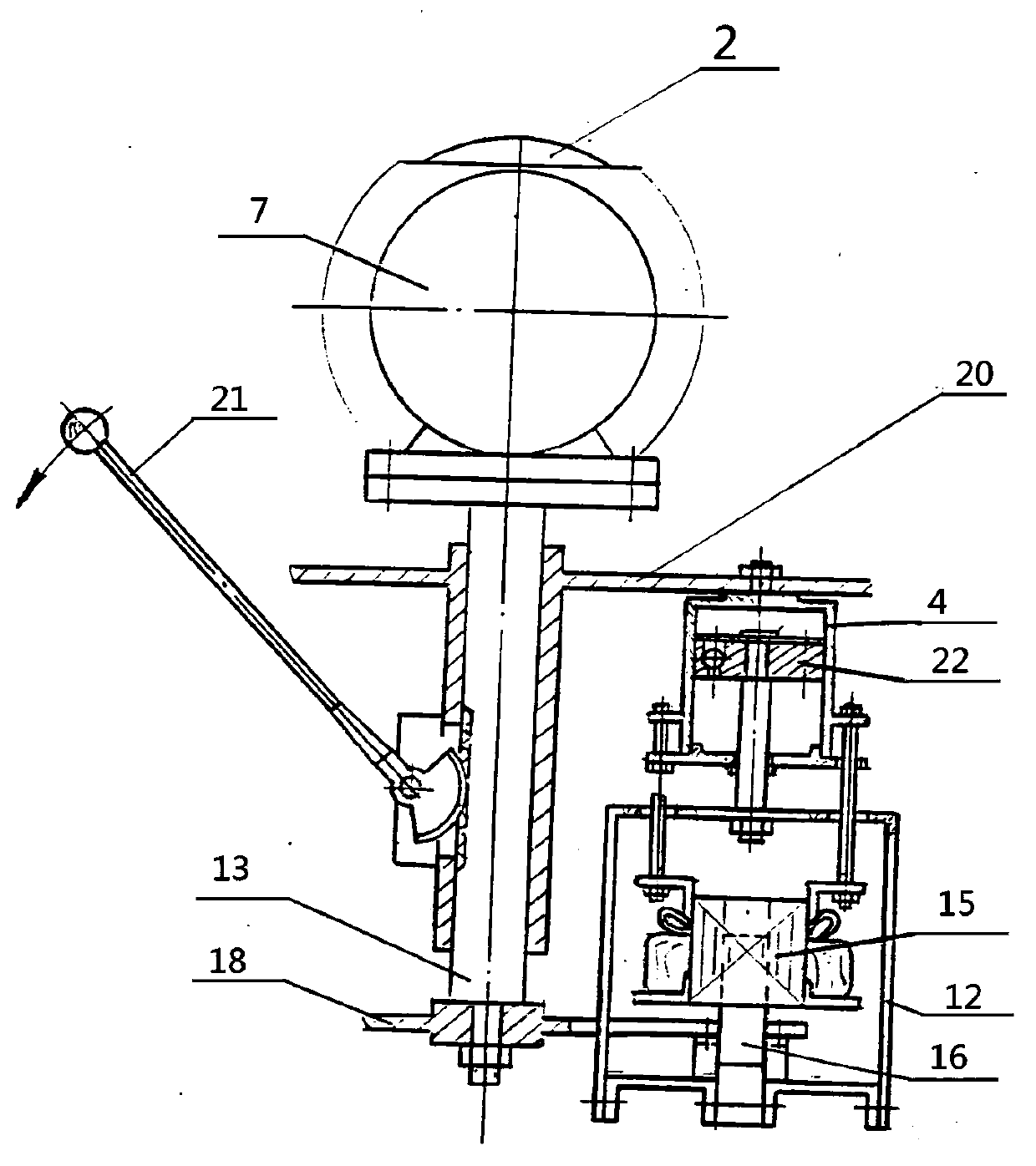

[0019] Refer to the attached Figure 1a , Figure 1b as well as Figure 2 to Figure 4 , Figure 5a with Figure 5b and Image 6 Describe the basic work of the multi-functional cutting machine that realizes manual and fully automatic working modes.

[0020] see figure 2 , 3 and 4, the cutting part of the cutting machine is composed of the cutting motor 7 and the cutting wheel 2. Cutting off emery wheel 2 is installed on the cutting motor 7, and is fixed on the feed guide post 13. The feed of the cutting machine is divided into manual cutting feed and fully automatic cutting feed. In the present invention, the manual cutting feed movement is to drive the rack by manually cutting the sector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com