Antibacterial modified graphene oxide and preparation method thereof

A kind of stone oxide, graphene technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems of continuous antibacterial, loss, loss of antibacterial properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

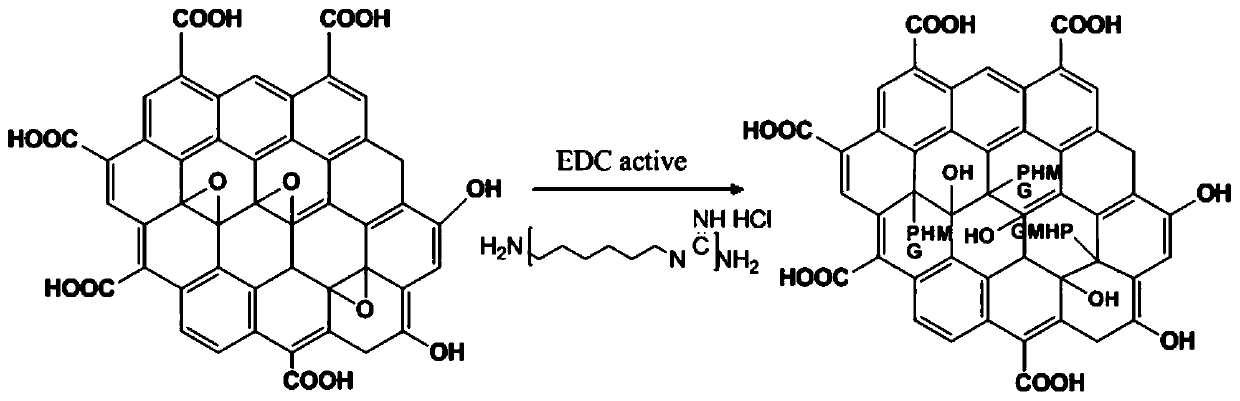

Method used

Image

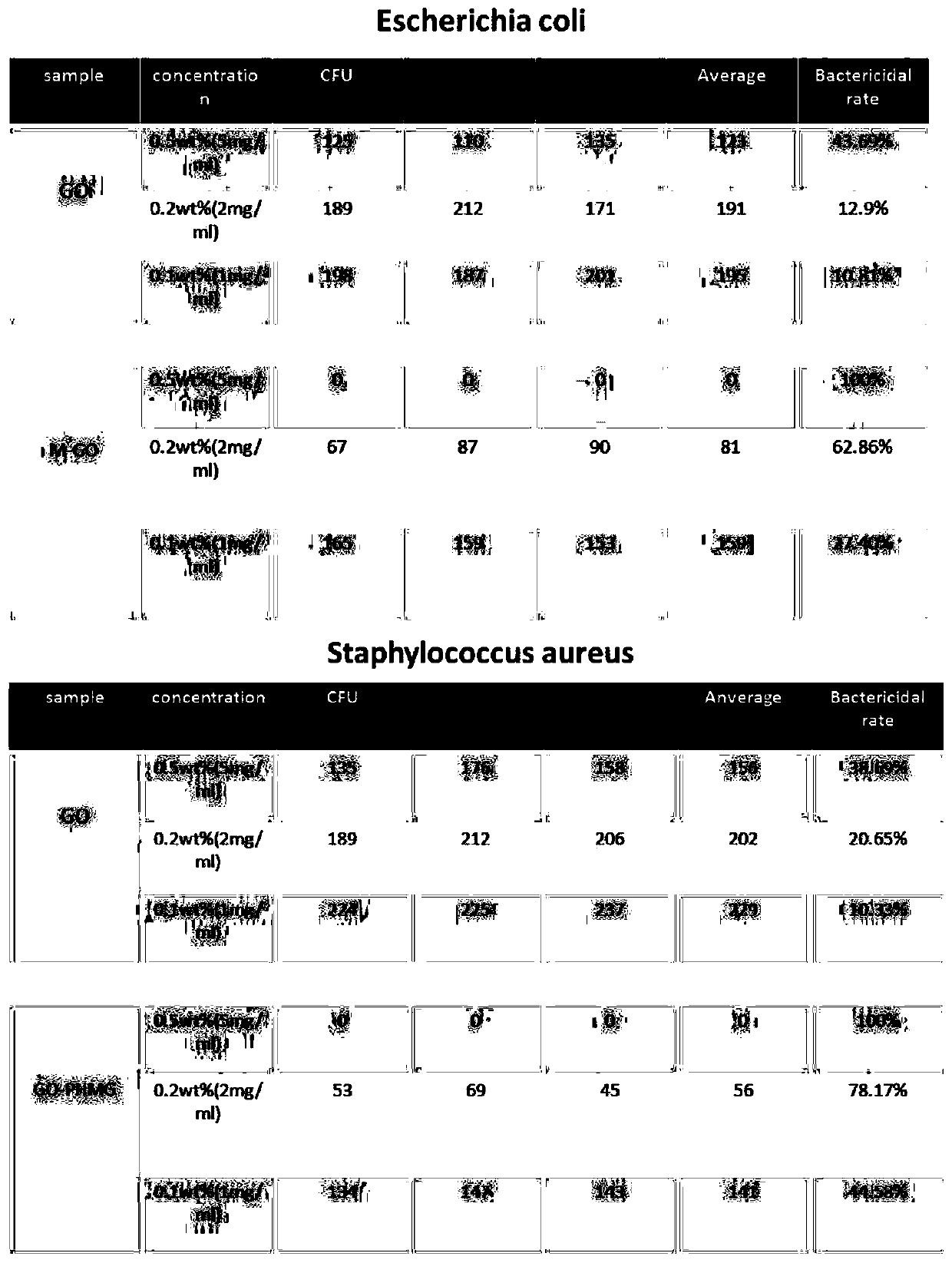

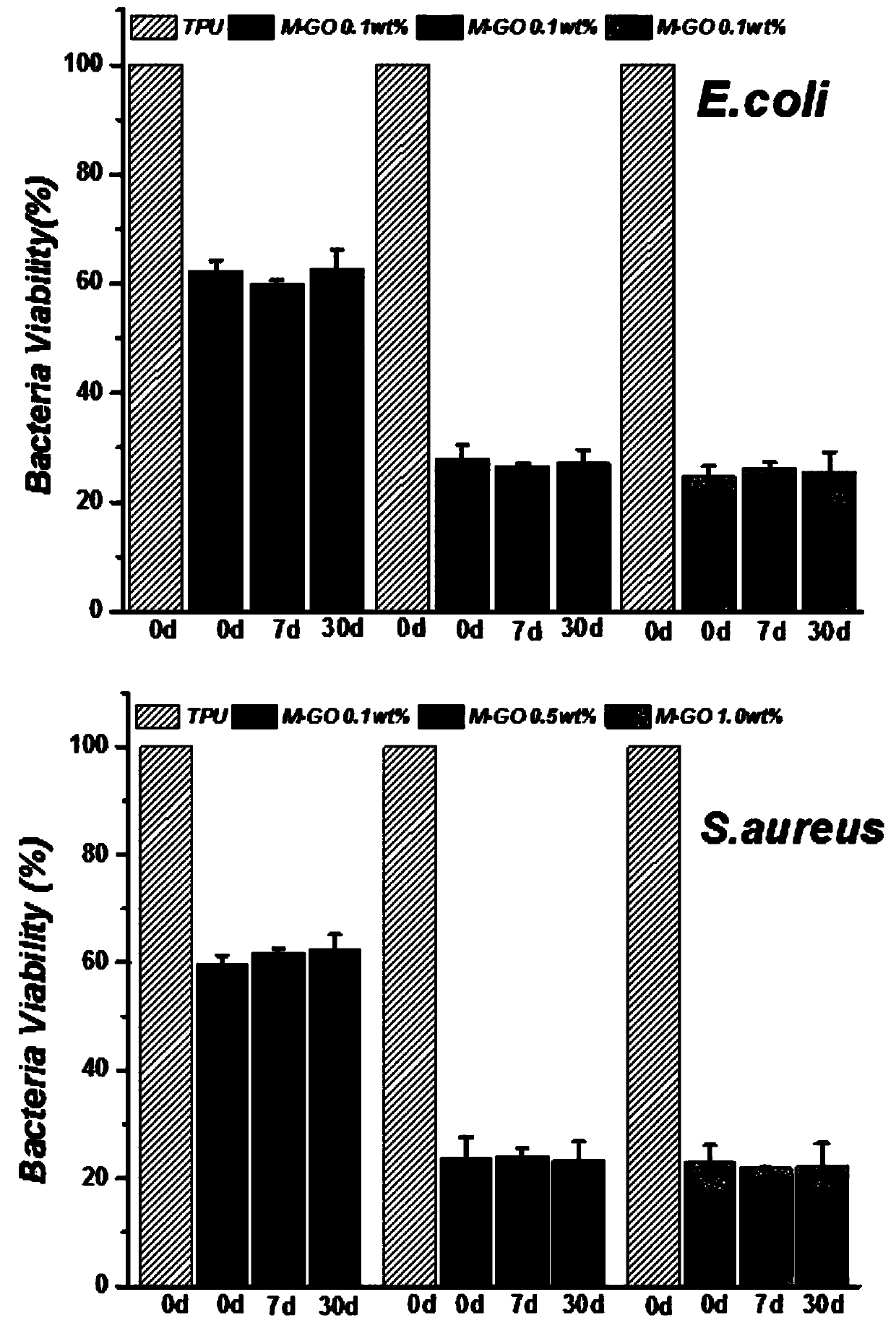

Examples

Embodiment 1

[0034] An antibacterial modified graphene oxide, the parts by weight of raw materials are: 0.01 part of graphene oxide, 0.03 part of antibacterial agent, and 50 parts of solvent.

[0035] The antibacterial agent is polyhexamethylene guanidine.

[0036] The preparation method of antibacterial modified graphene oxide comprises the following steps: (1) purification of graphene: Weigh a certain mass of graphene and ultrasonically disperse it in water, and centrifugally wash it three times to obtain purified graphene. (2) Weighing 0.01 part of graphene oxide and ultrasonically dispersing in 50 parts of deionized water for 30 minutes to obtain a uniformly dispersed graphene oxide dispersion. (3) At room temperature, add 0.03 parts of polyhexamethyleneguanidine, stir and ultrasonically stir with a mixer until the dispersion is uniform. (4) Adjust the pH of the solution to 11, and react at 60° C. for 48 hours. (5) The reactant was centrifuged and washed three times, and the product ...

Embodiment 2

[0038] An antibacterial modified graphene oxide, the parts by weight of raw materials are: 0.03 parts of graphene oxide, 0.09 parts of antibacterial agent, and 80 parts of solvent.

[0039] The antibacterial agent is gentamicin.

[0040] The preparation method of antibacterial modified graphene oxide comprises the following steps: (1) purification of graphene: a certain mass of graphene is weighed and ultrasonically dispersed in water, centrifuged and washed three times to obtain purified graphene oxide. (2) Weigh 0.03 parts of graphene oxide and ultrasonically disperse in 80 parts of deionized water for 30 minutes to obtain a uniformly dispersed graphene oxide dispersion. (3) At room temperature, add 0.09 parts of gentamycin, stir and sonicate with a mixer until the dispersion is uniform. (4) Adjust the pH of the solution to 11, and react at 60° C. for 48 hours. (5) The reactant was centrifuged and washed three times, and the product in the lower layer of the centrifuge tub...

Embodiment 3

[0042] An antibacterial modified graphene oxide, the parts by weight of raw materials are: 0.1 part of graphene oxide, 0.3 part of antibacterial agent, and 80 parts of solvent.

[0043] The antibacterial agent is penicillin.

[0044] The preparation method of antibacterial modified graphene oxide comprises the following steps: (1) purification of graphene: Weigh a certain mass of graphene and ultrasonically disperse it in water, and centrifugally wash it three times to obtain purified graphene. (2) Weigh 0.1 part of graphene oxide and ultrasonically disperse in 80 parts of deionized water for 30 min to obtain a uniformly dispersed graphene oxide dispersion. (3) At room temperature, add 0.3 parts of penicillin, stir and sonicate with a mixer until the dispersion is uniform. (4) Adjust the pH of the solution to 11, and react at 60° C. for 48 hours. (5) The reactant was centrifuged and washed three times, and the product in the lower layer of the centrifuge tube was freeze-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com