Mushroom double-sided solid inoculation machine

An inoculating machine, double-sided technology, applied in mushroom cultivation, horticulture, botanical equipment and methods, etc., can solve the problems of high labor cost, slow inoculation speed, low production yield, etc., to avoid bacterial infection and high work efficiency. , the effect of fast inoculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

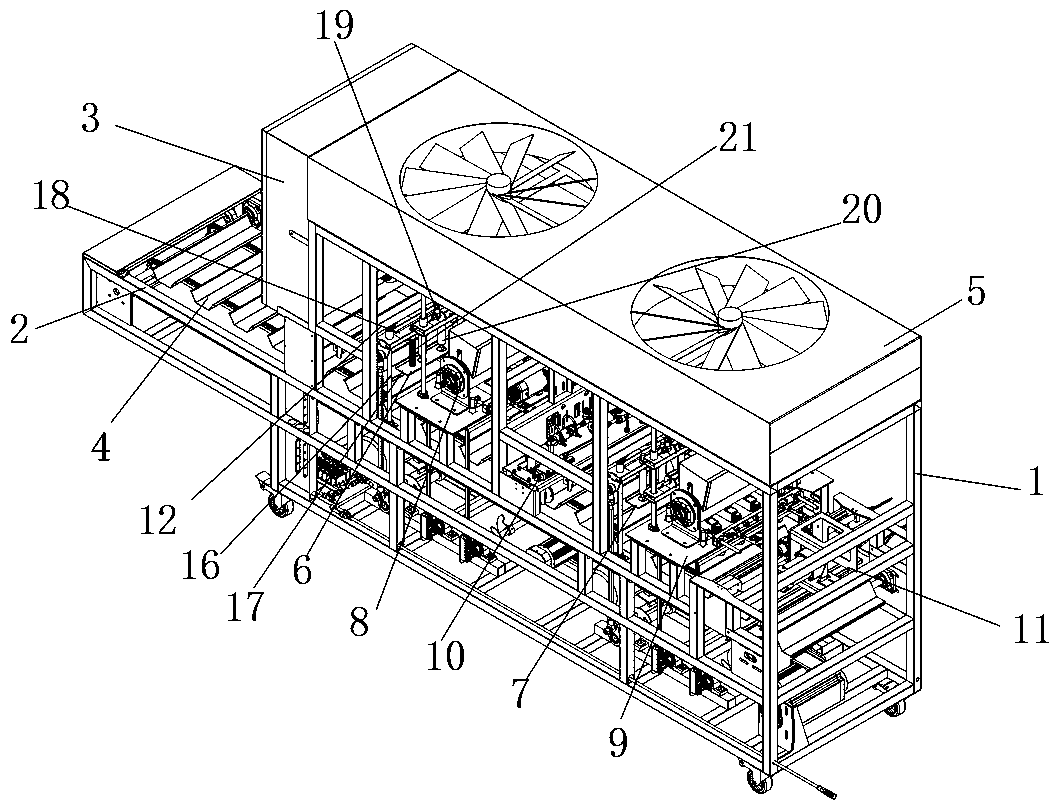

[0021] Such as figure 1 and figure 2 Shown, the shiitake mushroom double-sided solid inoculation machine includes a frame 1 and a chain conveying mechanism 2 installed on the frame 1 and a main control cabinet 3. The chain conveying mechanism 2 is equipped with a bacteria bag groove 4 for placing bacteria bags. A purification and disinfection mechanism 5 is fixed on the frame 1, and a first punching mechanism 6, a second punching mechanism 7, a first inoculation seed pressing mechanism 8, a second inoculation seed pressing mechanism 9, and a bag turning mechanism are also installed on the frame 1. 10 and the bag-out mechanism 11, the first punching mechanism 6, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com