Card edge connection unit

A technology for connection devices and card edge connectors, which is applied to parts, connections, coupling devices, etc. of connection devices, can solve problems such as poor contact, peeling off, insufficient contact pressure, etc., and achieve a stable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Hereinafter, Embodiment 1 of the present invention will be described based on the drawings.

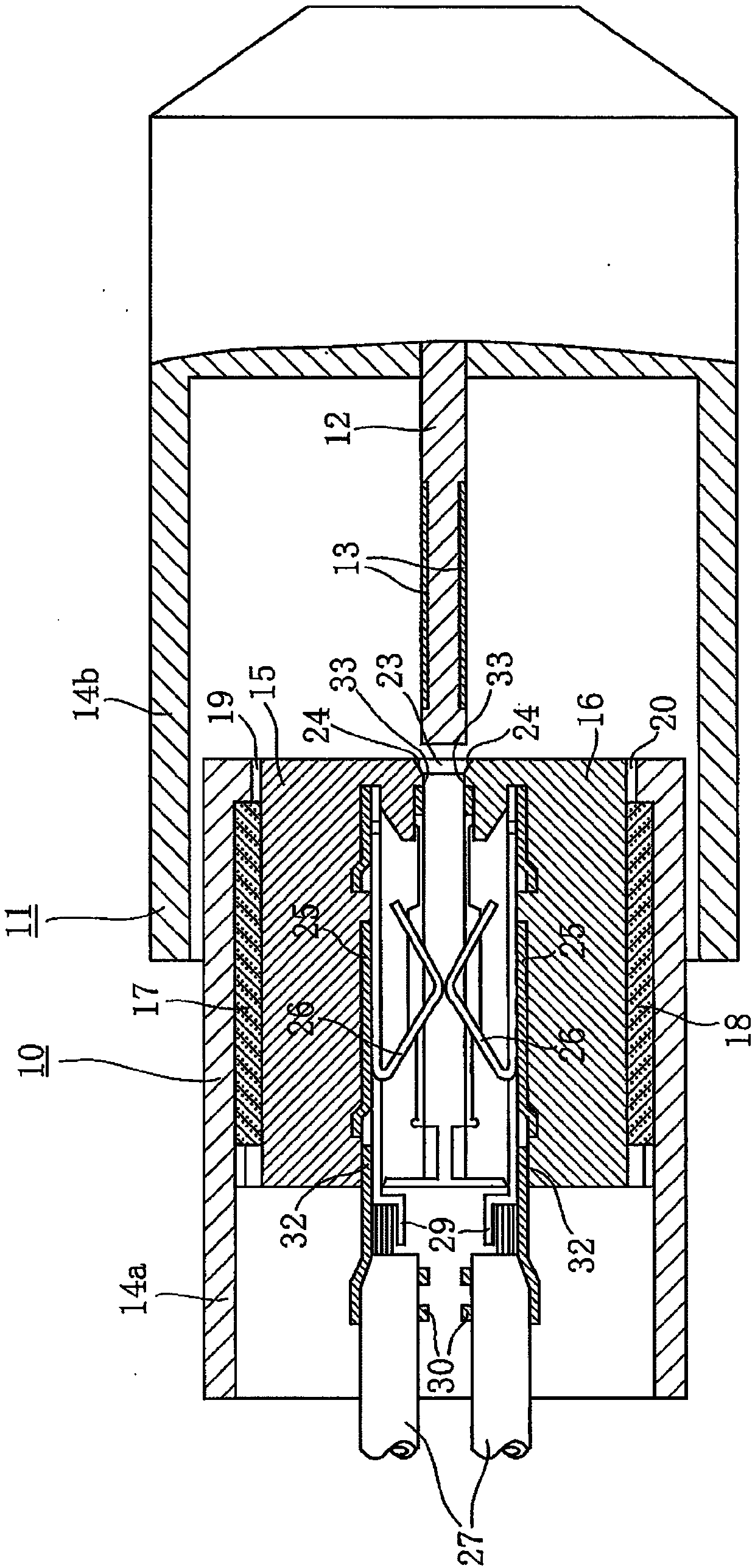

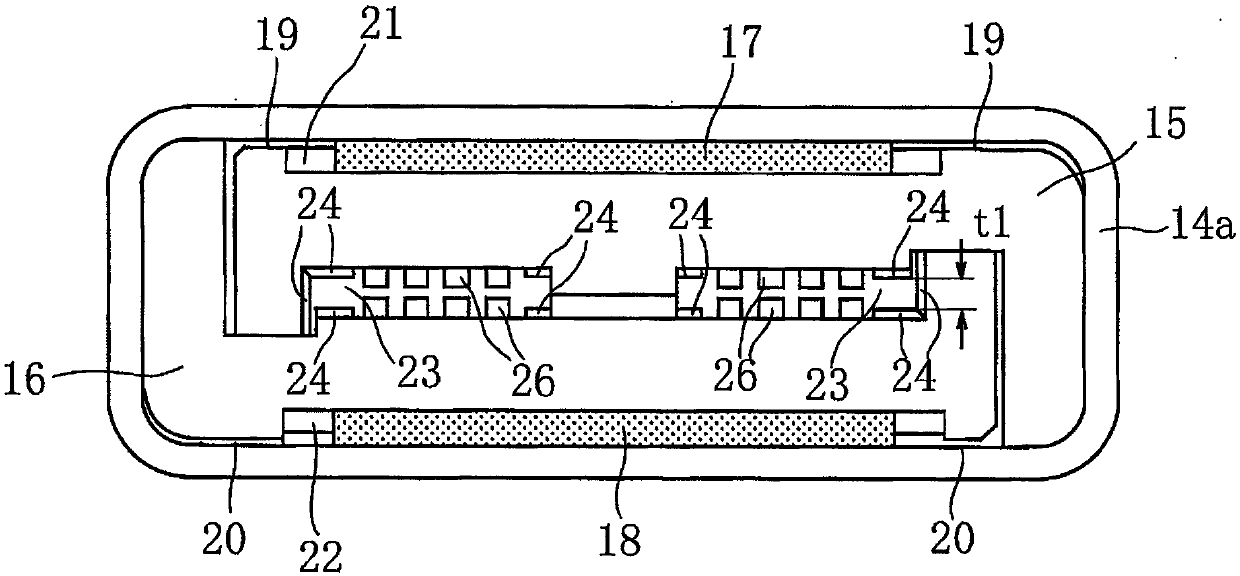

[0032] exist Figure 1 ~ Figure 4 Among them, 10 is a card edge connector, 11 is a card edge assembly, and the card edge connector 10 and the card edge assembly 11 constitute the card edge connection device of the present invention.

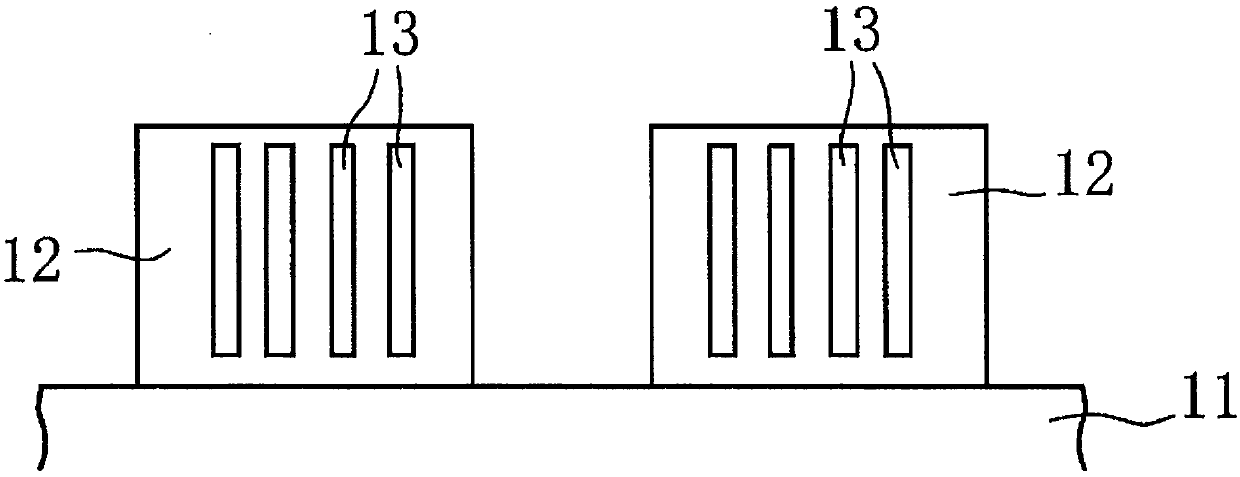

[0033] The card edge assembly 11 protrudes from the inner central part surrounded by the shell 14b with a connecting substrate 12 of a predetermined thickness, and on both sides of the connecting substrate 12 are arranged such as image 3 The electrode set 13 is shown.

[0034] The connecting substrate 12 is set to be, for example, 1.6 mm thick, and a tolerance of ±10% is allowed. Even if the connection board 12 has such a tolerance, it is desired to connect it to the card edge connector 10 stably and reliably, and the present invention aims to solve this problem.

[0035] The card edge connector 10 for this purpose is constructed as follows. ...

Embodiment 2

[0053] In the above-mentioned embodiment, the case where the electrode groups 13 are provided on both sides of the connection substrate 12 is described, so an example is shown in which the card edge connector 10 has a pair of elastic contacts 26 in contact with the electrode groups 13 on both sides.

[0054] However, the present invention is not limited thereto, and when the connection substrate 12 has the electrode group 13 on one side, the card edge connector 10 may have the elastic contact 26 in contact with the electrode group 13 on the one side. For example, in the case where the elastic contacts 26 are provided only on the lower inner case 16 side, it may also be configured such that the lower elastic body 18 is sandwiched between the lower inner case 16 and the outer case 14a, and the upper inner case The elastic contacts 26 and the upper elastic body 17 are not provided on the side of the body 15, and the connecting substrate 12 does not move forward or backward even wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com