Composite cathode material, cathode sheet, preparation method of cathode sheet, and lithium ion battery

A composite positive electrode material and lithium-ion battery technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of poor safety performance of batteries, easy oxygen release, energy density and power density that cannot meet energy demand, etc. Achieve the effect of high initial exothermic temperature and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides a composite positive electrode material suitable for lithium-ion batteries, which is mainly composed of three types of materials: A, B, and C.

[0067] Among them, the A material is a nickel-cobalt-lithium composite oxide (referred to as the first nickel-cobalt-lithium composite oxide), and its molecular formula is Li 1+x1 Ni 1-y1-z1 co y1 N z1 o 2 , wherein N is at least one of Mn and Al, -0.05<x1<0.1, y1=2Z, 0.10≤y1+z1≤0.14. Material A is a spherical aggregate of secondary particles formed by agglomeration of primary particles. The particle size of the primary particles is 200-400nm, and the crystal structure of the primary particles is layered. The particle size distribution of material A is narrow, the minimum particle size Dmin_A of material A is greater than 5um, and the average particle size D50 is 10-12um;

[0068] B material is another nickel-cobalt-lithium composite oxide (recorded as the second nickel-cobalt-lithium composite ox...

Embodiment 1A

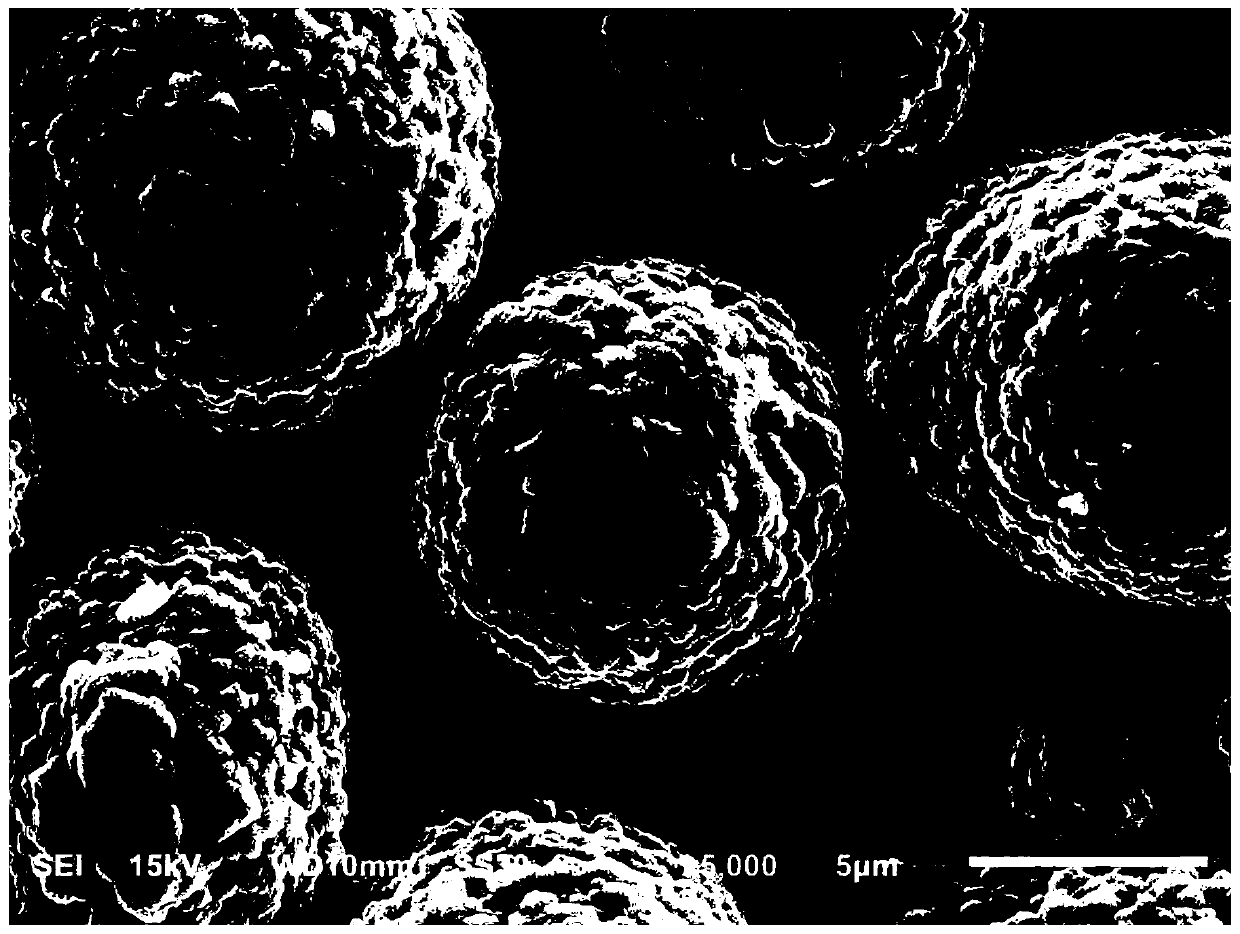

[0087] A0 material, molecular formula is Li 0.99 Ni0 0.88 co 0.08 mn 0.04 o 2 (ie molecular formula Li 1+x1 Ni 1-y1-z1 co y1 N z1 o 2 Among them, x1=0.01, y1=0.08, z1=0.04), purchased from Thornton New Energy Technology Co., Ltd., is a secondary particle spherical aggregate formed by primary particles of 200-400nm, and the minimum particle size of the A0 material is D min The value is 0.4um, and the average particle size D50 of the A0 material in this experimental example is 11.2um, which has a wide particle size distribution. figure 1It is the scanning electron microscope picture of the A0 material of this embodiment.

[0088] Material A0 passes through a powder classifier and is classified to obtain material A, and the minimum particle size of material A obtained is D min The value is 6.2um, so that the particle size distribution of material A obtained by classification is further narrowed compared with material A0. The average particle diameter D50 of material A o...

Embodiment 2A

[0097] Compared with Example 1A, the composite positive electrode material is composed of A, B and C, the mass ratio of A:B:C is 74.16%:24.09%:1.75%, and the rest are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com