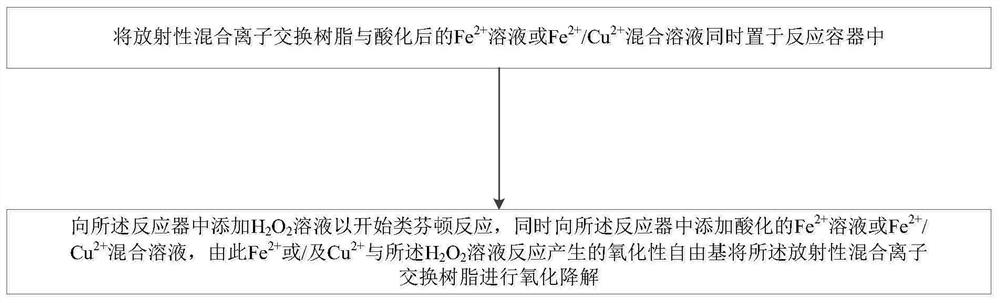

Method for Treating Radioactive Mixed Ion Exchange Resin Using Fenton-like Oxidation

A technology of mixed ion exchange and exchange resin, which is used in radioactive purification, nuclear engineering and other directions to reduce residual solid slag, ensure degradation effect, and have strong applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

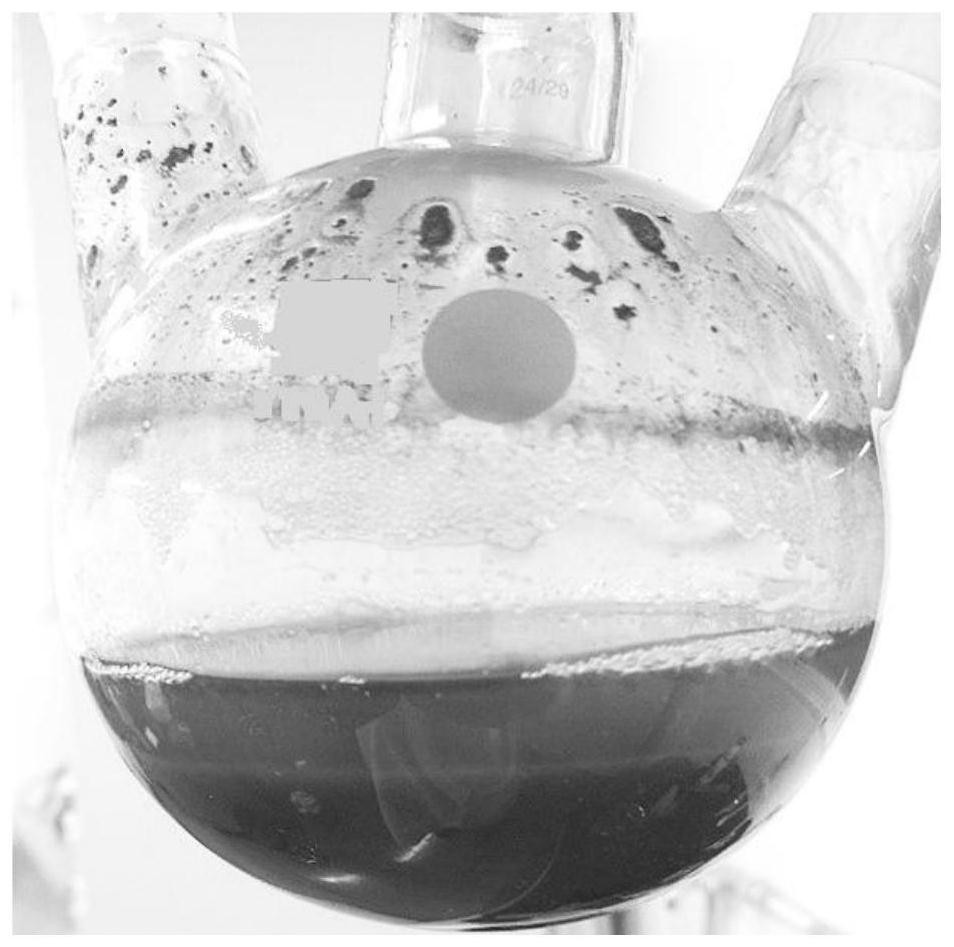

Embodiment 1

[0049] The mixed resin of ZG C NR 50 strongly acidic cation exchange resin and ZG A NR 170 strongly basic anion exchange resin is processed by Fenton-like oxidation method, the total treatment capacity is 20g, and the mass ratio of cation exchange resin and anion exchange resin is 1: 1. The water content is 51.6wt% and 55wt%. In order to investigate the effect of acid addition and no acid addition on the oxidative degradation of mixed ion exchange resins, a group of experiments directly added Fe at a concentration of 0.1mol / L to the reactor. 2+ and Cu at a concentration of 0.1mol / L 2+ solution (i.e. catalyst solution) 50mL, then continue to dropwise add this catalyst solution 50mL and volume fraction be 30% H 2 o 2 Solution 200mL, the initial pH value of reaction solution in this reactor is 1.85; Another group of experiments directly adds the catalyst solution (Fe 2+ and Cu 2+ The concentration is 0.1mol / L, H 2 SO 4 The concentration is 1mol / L), then continue to drip thi...

Embodiment 2

[0055] The mixture of cation exchange resin and anion exchange resin is treated by Fenton-like oxidation method, the total treatment capacity is 20g, the mass ratio of cation exchange resin and anion exchange resin is 1:1, and a total amount of 50mL of sulfuric acid is added to the reactor Catalyst solution after acidification (wherein Fe 2+ and Cu 2+ concentration is 0.2mol / L), and then continue to dropwise add this catalyst solution 50mL and volume fraction be 30% H 2 o 2 The solution is 200mL; mechanical stirring is carried out during the reaction, the reaction temperature is 96±1°C, after 240min of reaction, record the concentration of H 2 SO 4 The catalyst solution of acidification is to the treatment result of mixed ion exchange resin, see table 2:

[0056] Table 2 Example 2 test results

[0057] h 2 SO 4 Concentration (mol / L)

[0058] The results in Table 2 show that after reacting for 240min, the concentration of 0.5-2mol / L H 2 SO 4 Solution, the d...

Embodiment 3

[0060] The mixture of cation exchange resin and anion exchange resin is treated by Fenton-like oxidation method, the total treatment capacity is 20g, the mass ratio of cation exchange resin and anion exchange resin is 1:1, and a total amount of 50mL of sulfuric acid is added to the reactor Acidified catalyst solution (wherein H 2 SO 4 The concentration is 1mol / L), then continue to dropwise add catalyst solution 50mL and volume fraction be 30% H 2 o 2 The solution is 200mL; mechanical stirring is carried out during the reaction, and the reaction temperature is 96±1°C. After reacting for 240 minutes, record the treatment results using different types of catalyst solutions respectively, as shown in Table 3:

[0061] Table 3 Example 3 test results

[0062] Catalyst type pH value COD value (mg / L) Weight loss rate (%) 0.1mol / L Cu 2+

[0063] The results in Table 3 show that for the oxidative decomposition of mixed ion exchange resins, Fe 2+ or Fe 2+ / Cu ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com