System and method for azimuth element and distortion testing of optical remote sensor

An optical remote sensor and internal orientation element technology, which is used in optical instrument testing, machine/structural component testing, and optical performance testing, etc. It can solve problems such as low efficiency, huge demand for testing equipment, and untimely test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

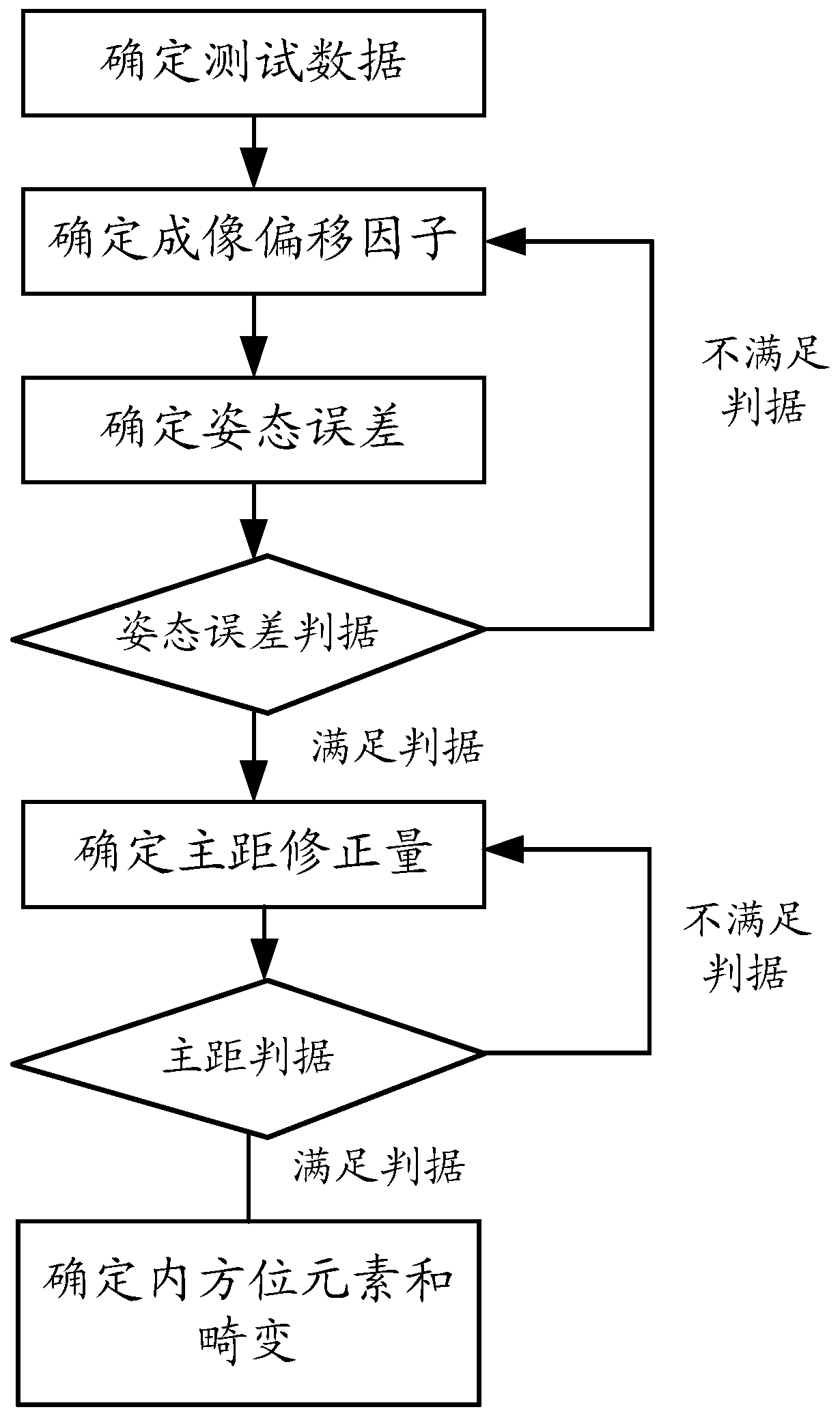

Method used

Image

Examples

Embodiment Construction

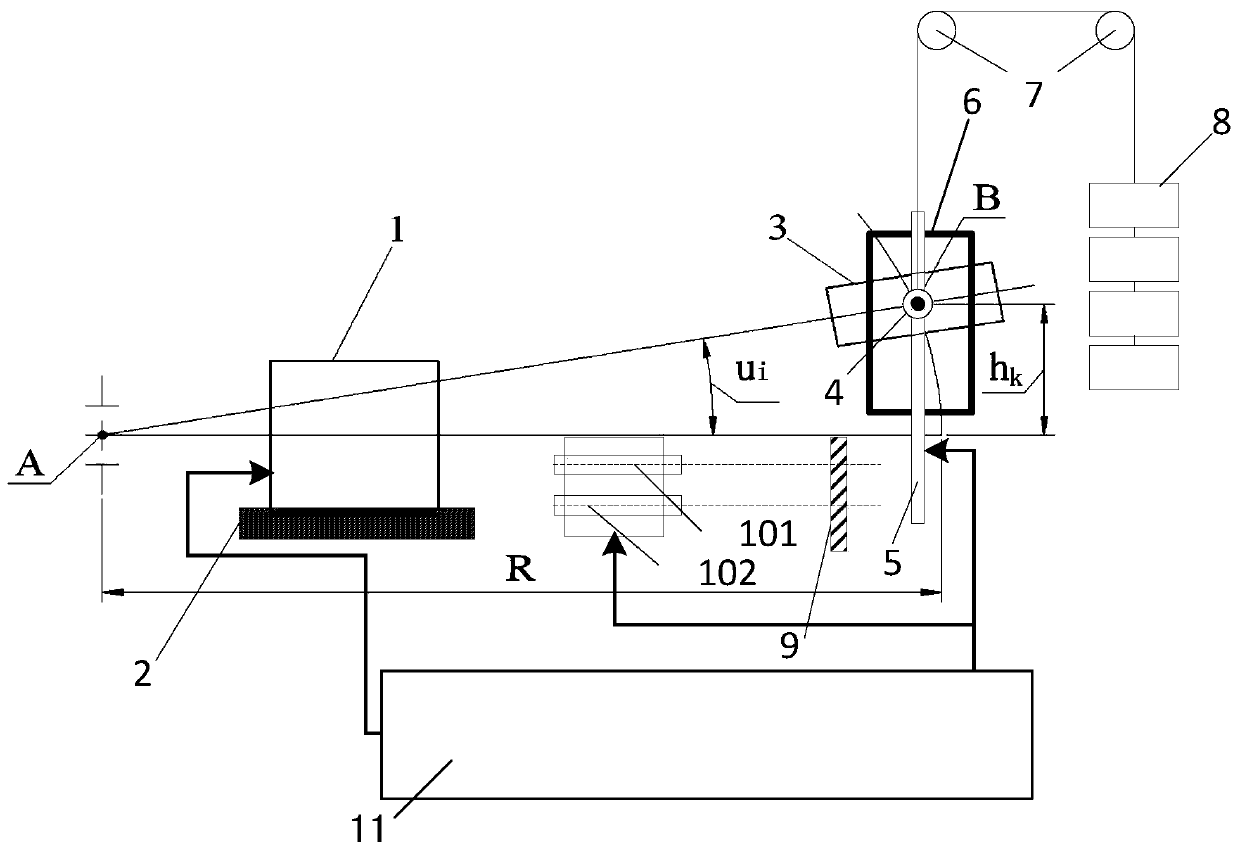

[0064] An optical remote sensor internal orientation element and distortion test system of the present invention is attached figure 2 As shown, it includes: test platform 2, collimator 3, rotating mechanism, slider 4, guide rail 5, motion support 6, fixed pulley 7, counterweight 8, plane mirror 9, first photoelectric autocollimator 101 , a second photoelectric autocollimator 102 , and a data processing system 11 . The optical remote sensor 11 to be tested is placed on the test platform 2, and the direction of its line array CCD is adjusted to be perpendicular to the earth by optical means. The collimator 3 simulates parallel light at infinity, and projects the reticle at the focal plane of the collimator onto the focal plane of the camera under test. The collimator 3 is connected with the counterweight 8 through the fixed pulley 7 to realize the weight balance of the collimator system and generate a collimated light source injected into the optical remote sensor 1 to be test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com