Fast-response redundant membrane type thermocouple

A thermocouple, fast-response technology, applied in thermometers using electrical/magnetic components directly sensitive to heat, measuring heat, using electrical devices, etc., can solve problems such as shortening the service life of heated components, large failures, and economic losses Achieve the effect of avoiding inaccurate measurement results, improving accuracy, and widening temperature measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

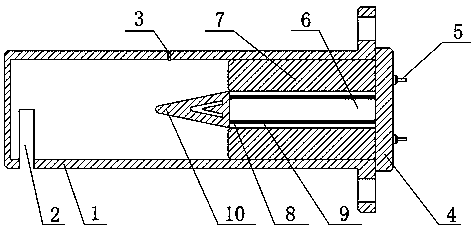

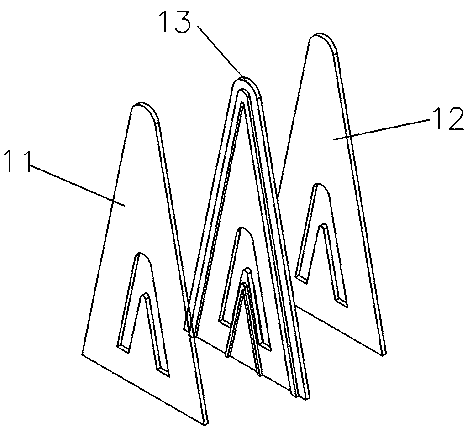

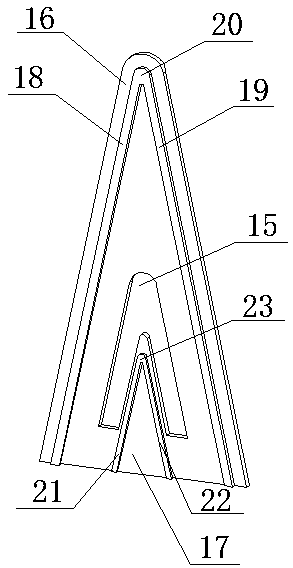

[0020] see Figure 1-3 , the present invention provides a technical solution: a fast-response redundant membrane thermocouple, including a stagnation cover 1, an air inlet 2 is provided on one side of the stagnation cover 1, and an upper end of the stagnation cover 1 is provided with The air outlet 3, the terminal block 4 is installed on one side of the stagnation cover 1, the terminal block 4 is provided with a wiring port 5, the inner cavity of the stagnation cover 1 is also provided with a fixed seat 6, and the fixed seat 6 One end of the terminal block 4 is connected to one side, and high-temperature cement 7 is filled between both sides of the fixed seat 6 and the inner side of the stagnation cover 1, and a lead wire protection tube 8 is provided inside the fixed seat 6, and the lead wire protection tube 8 is penetrated inside. There is a lead wire 9, the other end of the fixing seat 6 is connected to a sandwich structure 10, and the sandwich structure 10 is connected to ...

Embodiment 2

[0023] Such as Figure 4 As shown, one side of the stagnation cover 1 is provided with an air inlet 2, the upper end of the stagnation cover 1 is provided with an air outlet 3, one side of the stagnation cover 1 is installed with a terminal block 4, and the terminal block 4 is provided with Wiring port 5, the inner cavity of the stagnation cover 1 is also provided with a fixing seat 6, and one end of the fixing seat 6 is connected to one side of the wiring seat 4, and a high temperature is filled between both sides of the fixing seat 6 and the inner side of the stagnation cover 1 Cement 7, the inside of the fixed base 6 is provided with a lead wire protection tube 8, and the inside of the lead wire protection tube 8 is threaded with a lead wire 9, and also includes a corundum tube 24, the corundum tube 24 is arranged between the high temperature cement 7, and the One end of the corundum tube 24 is connected to the fixed seat 6, and a dual wire protection tube 25 is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com