Scaffolding construction method used for super shallow buried large underground space

A technology of underground space and construction method, which is applied to underground chambers, shaft linings, tunnel linings, etc. It can solve problems such as lack of ultra-shallow buried excavation, complex construction steps, and many construction conversions, so as to save component construction and demolition time, save the cost of supporting structures, and improve the structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

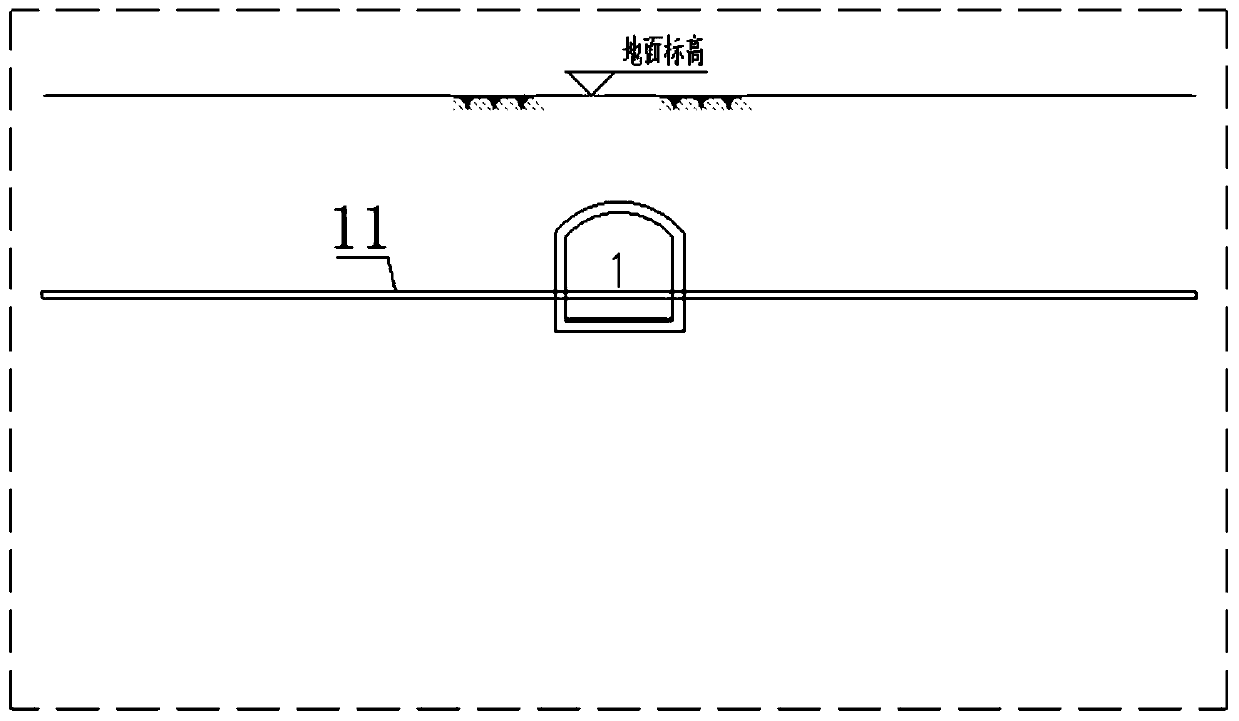

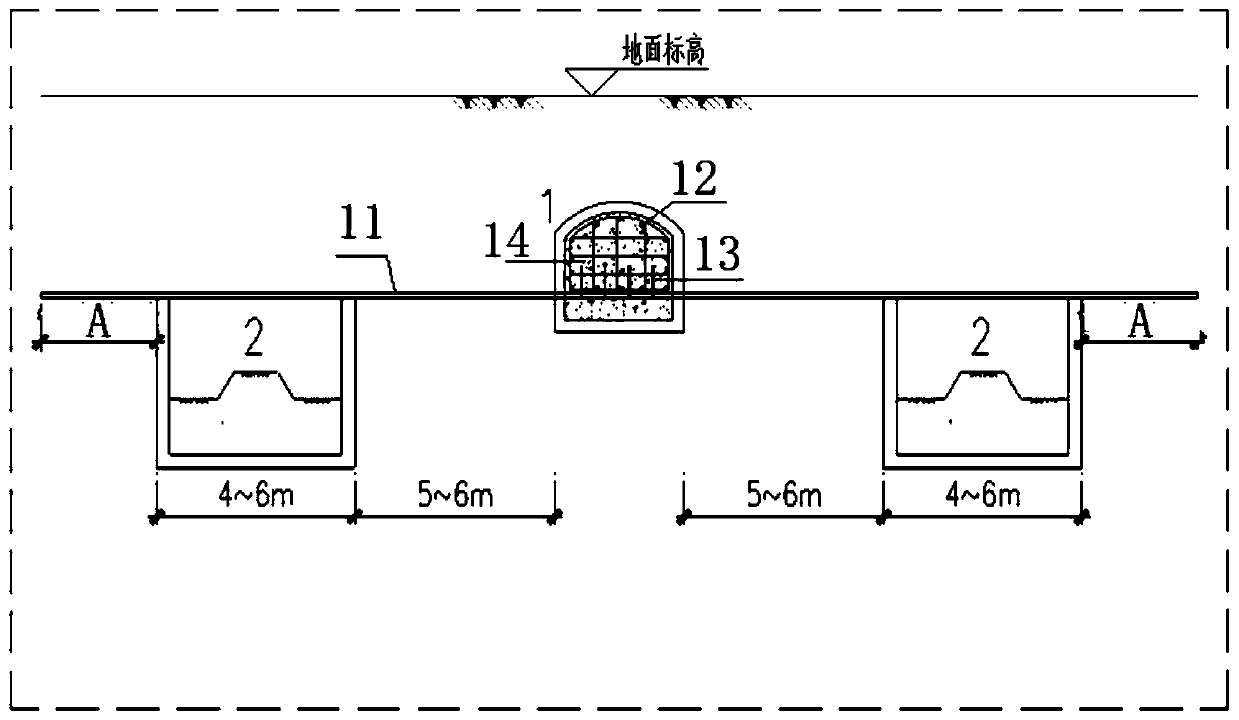

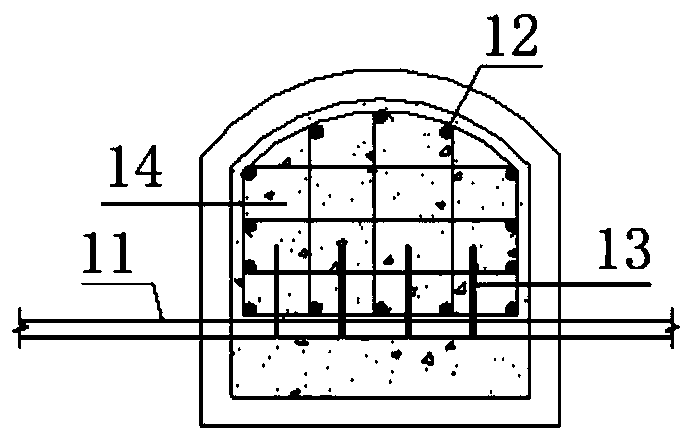

[0048] see Figure 1 to Figure 7 , shows the scaffolding construction method for ultra-shallow buried large underground space of the present invention.

[0049] The scaffold construction method for ultra-shallow buried large underground space includes the following steps:

[0050] Step 1: Enclose the available open space on both sides of the road, construct a construction shaft for underground excavation within the enclosure, and construct a horizontal cross passage in the shaft for excavation during the excavation of the underground space structure to be constructed under the road and feeding. The available space on both sides of the road can be fenced without affecting traffic and pipelines. The number of construction shafts and cross passages is determined by the builder based on the length, height, width, construction period and site conditions of the underground structure.

[0051] Step 2: Construct the first guide tunnel 1 at the selected location in the underground spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com