Smart cable, smart cable preparation method and smart cable safety state detection method

A technology of intelligent cable and safe state, which is applied in geotechnical structure and large concrete structure, intelligent cable preparation, intelligent cable safety state detection, bridge structure, intelligent cable field, and can solve problems such as layout difficulties and achieve seamless Effects of installation error, low insertion loss, and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

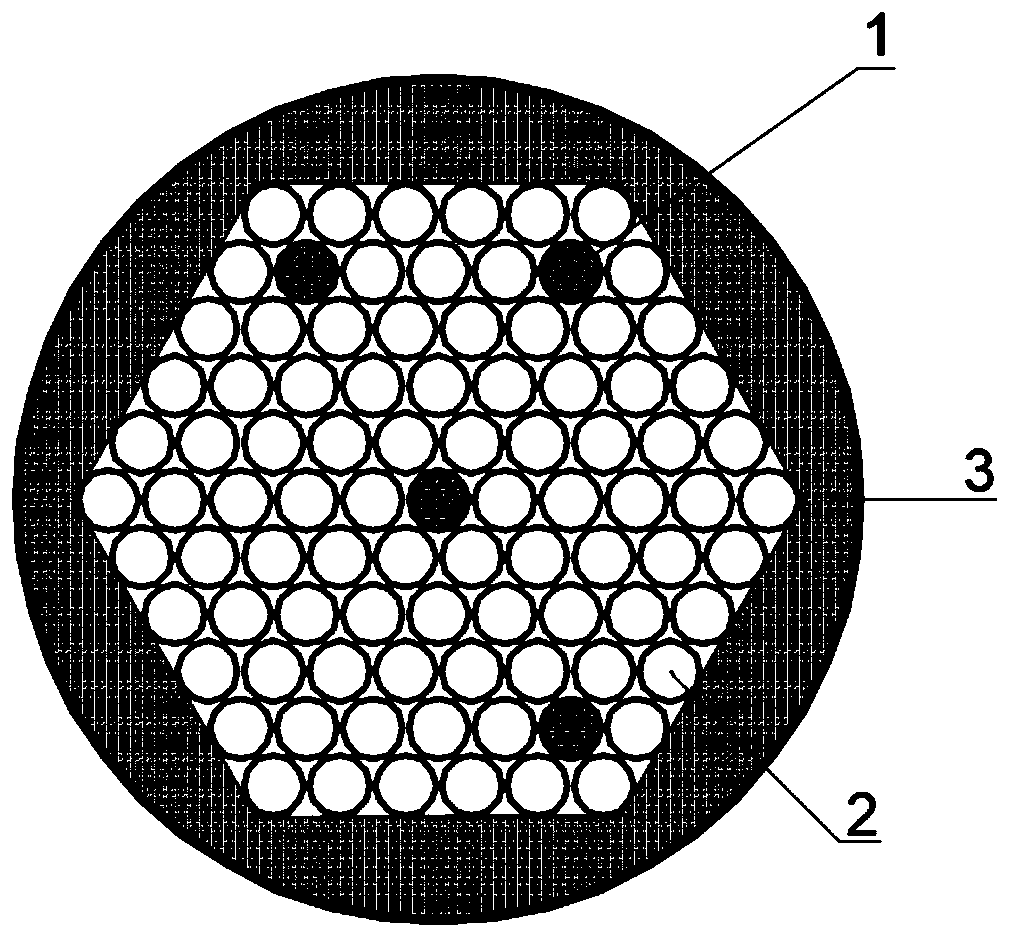

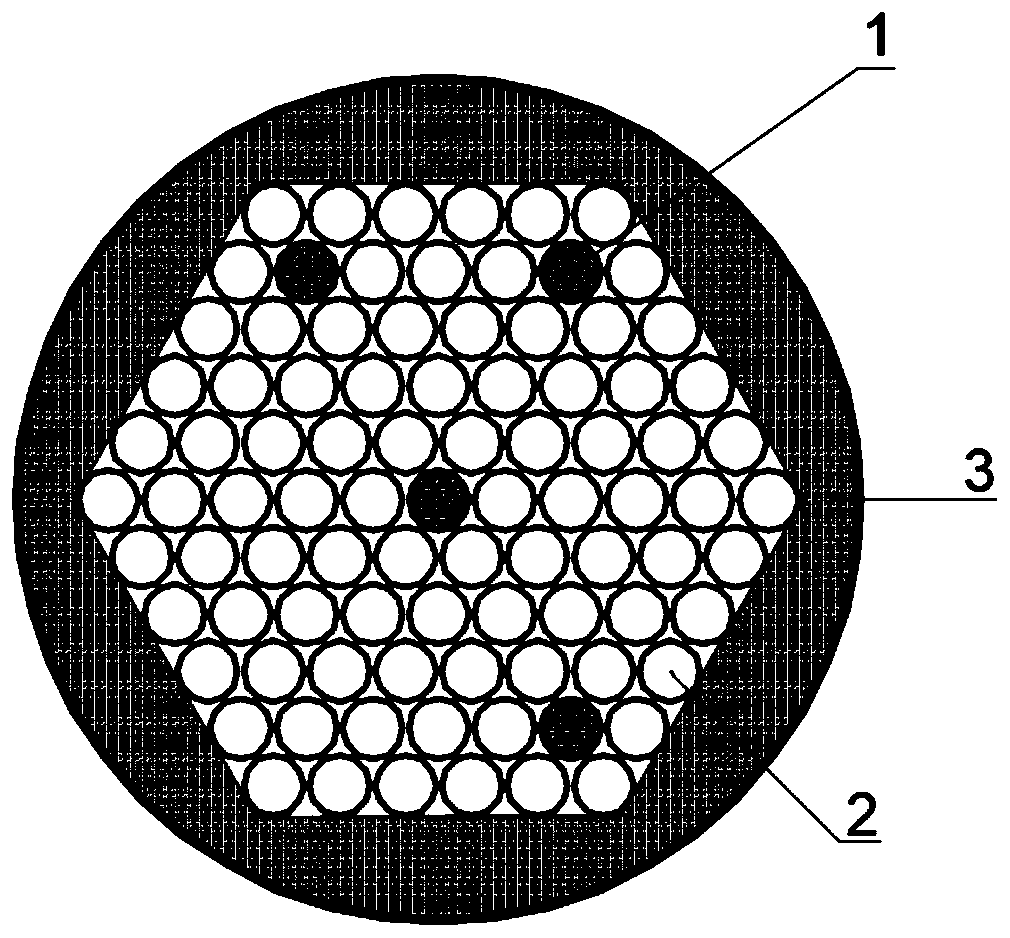

[0041] figure 1 It is a schematic cross-sectional view of an embodiment of the present invention, including a fiber-reinforced optical fiber tie bar 1, a tie bar 2 (the tie bar 2 adopts steel wire or steel strand in this embodiment), and a sheath 3. The fiber-reinforced optical fiber tie bars 1 and the tie bars 2 are equally long and thickly blanked. When the smart cable is processed and formed, the fiber-reinforced optical fiber tie bar 1 replaces at least one tie bar 2 in the cable, and the outer cover of the cable is covered with a sheath 3. The end of the dragline has an anchor head (not shown).

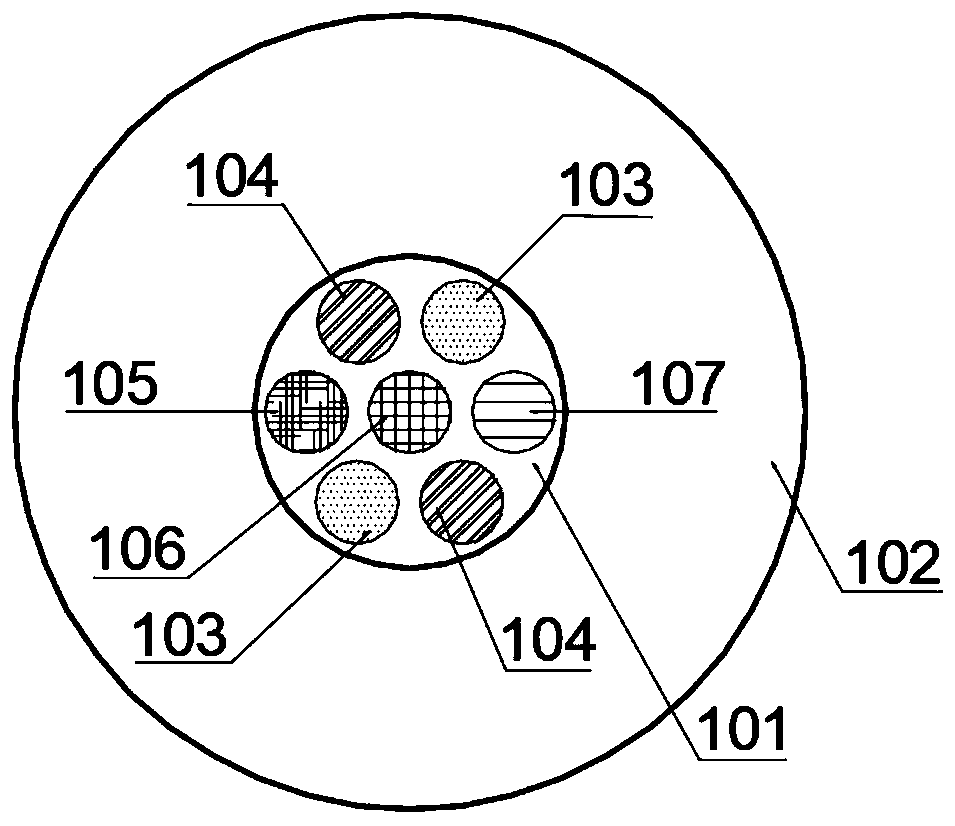

[0042] combine figure 2, the multi-core optical fiber 101 is placed in the center of the fiber-reinforced plastic rib 102 along the length direction of the rib, and the fiber-reinforced optical fiber tie bar 1 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com