Nitrogen-containing organic compounds and application of compounds in organic light emission diodes

A technology of organic compounds and compounds, applied in organic chemistry, electrical solid devices, electrical components, etc., can solve different problems and achieve the effects of not being easy to gather, preventing energy loss, and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

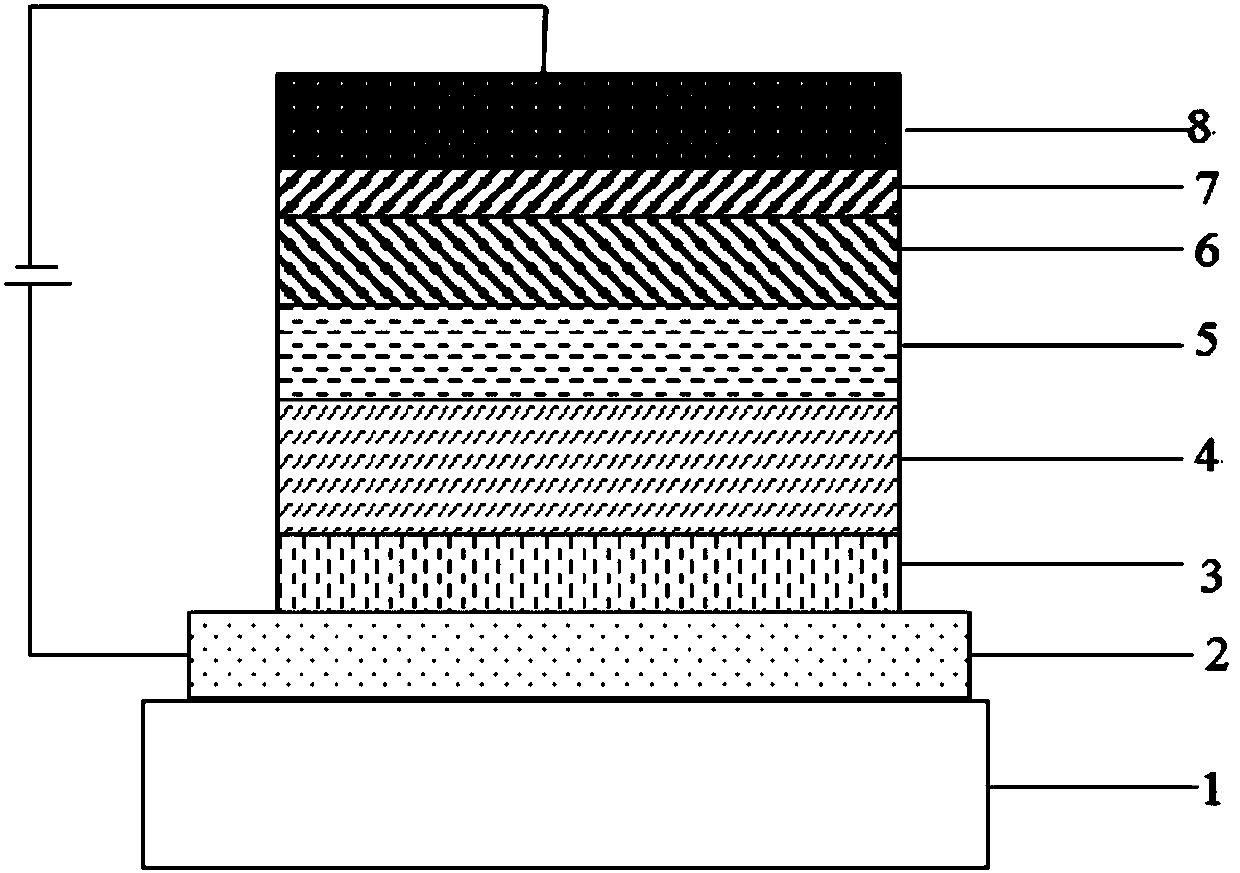

Method used

Image

Examples

Embodiment 1

[0050] The synthesis of embodiment 1 compound 1

[0051] The synthetic steps of compound are as follows:

[0052]

[0053] In a 500mL three-neck flask, under the protection of nitrogen, add 0.03mol raw material A-1, 0.03mol raw material B-1, 250mL toluene and stir to mix, then add 0.09mol potassium tert-butoxide, 0.0015mol Pd 2 (dba) 3 , heated to 110°C, reflux reaction for 24 hours; naturally cooled to room temperature, filtered, and the filtrate was subjected to vacuum rotary evaporation (-0.09MPa, 85°C), and passed through a neutral silica gel column to obtain compound 1. The HPLC purity was 99.3%, and the yield was 76.3%;

[0054] Elemental analysis structure (molecular formula C 41 h 23 N 3 O): theoretical value C, 85.84; H, 4.04; N, 7.33; found value: C, 85.82; H, 4.05; N, 7.34. MS m / z: 573.42[M+H] + , theoretical value: 573.65.

Embodiment 2

[0055] The synthesis of embodiment 2 compound 13

[0056] The synthetic steps of compound are as follows:

[0057]

[0058]

[0059] In a 500mL three-neck flask, under the protection of nitrogen, add 0.03mol raw material B-2, 0.03mol p-dibromobenzene, 250mL toluene and stir to mix, then add 0.09mol potassium tert-butoxide, 0.0015mol Pd 2 (dba) 3 , heated to 110°C, and refluxed for 24 hours; naturally cooled to room temperature, filtered, and the filtrate was subjected to reduced-pressure rotary evaporation (-0.09MPa, 85°C), and passed through a neutral silica gel column to obtain intermediate C-1;

[0060] In a 250mL three-neck flask, under the protection of nitrogen, add 0.02mol of intermediate C-1, 0.03mol of pinacol diborate, 0.05mol of potassium carbonate, 0.002mol of Pd(PPh 3 ) 4 and 100ml of toluene / water (volume ratio=5:1), stir and mix, heat to 80°C, react for 24 hours, take a sample point plate, it shows that there is no intermediate C-1 remaining, and the re...

Embodiment 3

[0063] The synthesis of embodiment 3 compound 26

[0064] The synthetic steps of compound are as follows:

[0065]

[0066] In a 500mL three-neck flask, under the protection of nitrogen, add 0.03mol raw material A-1, 0.03mol raw material B-3, 250mL toluene and stir to mix, then add 0.09mol potassium tert-butoxide, 0.0015mol Pd 2 (dba) 3 , heated to 110°C, and refluxed for 24 hours; naturally cooled to room temperature, filtered, and the filtrate was subjected to vacuum rotary evaporation (-0.09MPa, 85°C), and passed through a neutral silica gel column to obtain compound 26. The HPLC purity was 99.3%, and the yield was 76.3%;

[0067] Elemental analysis structure (molecular formula C 41 h 23 N 3 O): theoretical value C, 85.84; H, 4.04; N, 7.33; found value: C, 85.82; H, 4.05; N, 7.34. MS m / z: 573.42[M+H] + , theoretical value: 573.65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com