Liquid fertilizer for improving fruit-corn fruit quality and preparation method thereof

A liquid fertilizer, fruit corn technology, applied in the directions of liquid fertilizer, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of small fruit, less nutrients, poor taste, etc., and achieve easy absorption and nutritional balance. , to prevent the effect of empty fruit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

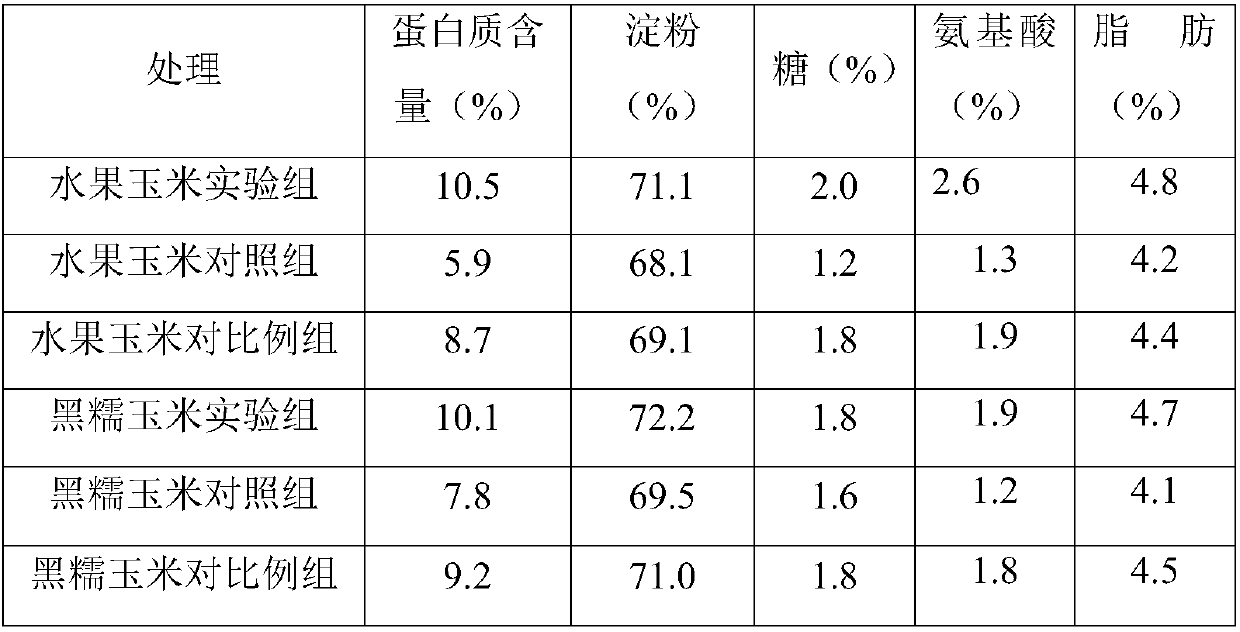

Examples

Embodiment 1

[0043] The isolation and identification of embodiment 1 Streptomyces bacterial strain (Streptomyces)

[0044] 1. Experimental materials and conditions

[0045] (1) Soil samples collected in a certain place in Chenzhou City, Hunan Province.

[0046](2) The components per liter of the liquid medium are as follows: 3.0 g of beef extract, 10.0 g of peptone, 5.0 g of sodium chloride, dilute to 1 liter of water, and the pH is 7.5.

[0047] The components per liter of solid medium are as follows: beef extract 3.0g, peptone 10.0g, sodium chloride 5.0g, agar 15-25g, water to 1 liter, pH 7.5.

[0048] The culture medium was divided into aliquots and sterilized in an autoclave (121°C, 30min).

[0049] (3) Sterile operating conditions: All utensils and utensils must be sterilized in an autoclave (121°C, 30min), and operations such as inoculation are carried out in an ultra-clean workbench.

[0050] (4) Conditions for culturing strains: place them in a light incubator (14L: 10D) at 25±1...

Embodiment 2

[0065] Embodiment 2 A kind of preparation of the liquid fertilizer that improves fruit corn fruit quality

[0066] A preparation method for improving the quality of fruit corn fruit comprises the following steps:

[0067] S1. Preparation of culture medium: soak 1000g of soybeans for 10 hours, put them into a refiner and grind them into soybean milk, filter out the bean dregs, put the filtrate in a clean fermenter, add white sugar to the filtrate, add water to The concentration of sugar in the medium is 100g / L, and the pH is 7.5;

[0068] S2. inoculation: get the liquid spawn of Streptomyces bacterial strain " TY-001# ", inoculate in the culture medium, stir evenly; There are 200,000,000 viable bacteria per milliliter in the liquid spawn; The ratio of liquid spawn and culture medium 165g:250L;

[0069] S3. Fermentation: Turn on the oxygen pump, continuously feed oxygen into the fermenter during the fermentation process, and add an appropriate amount of defoamer according to t...

Embodiment 3

[0072] Embodiment 3 A kind of preparation of the liquid fertilizer that improves fruit corn fruit quality

[0073] A preparation method for improving the quality of fruit corn fruit comprises the following steps:

[0074] S1. Preparation of culture medium: soak 1000g of soybeans for 10 hours, put them into a refiner and grind them into soybean milk, filter out the bean dregs, put the filtrate in a clean fermenter, add white sugar to the filtrate, add water to The concentration of sugar in the medium is 100g / L, and the pH is 7.5;

[0075] S2. inoculation: get the liquid spawn of Streptomyces bacterial strain " TY-001# ", inoculate in the culture medium, stir evenly; There are 200,000,000 viable bacteria per milliliter in the liquid spawn; The ratio of liquid spawn and culture medium 165g:250L;

[0076] S3. Fermentation: Turn on the oxygen pump, continuously feed oxygen into the fermenter during the fermentation process, and add an appropriate amount of defoamer according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com