Manufacturing process of a flexible thermal insulation board

A production process and insulation board technology, which is applied in the field of building materials, can solve problems such as poor insulation effect, low tensile strength of insulation boards, and low combustion performance, so as to improve production efficiency, solve fire safety problems, and achieve the effect of insulation performance and fire protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The raw material composition of embodiment 1 includes:

[0052] Siliceous minerals, including 50 parts of active microsilica, 5 parts of silicon dioxide, 6 parts of vitrified microbeads and 50 parts of quartz powder;

[0053] Binders, including 50 parts of cement, 30 parts of calcium oxide and 10 parts of fly ash;

[0054] Mineral activator, including 105 parts of sodium silicate and 5 parts of sodium fluorosilicate;

[0055] Additives, including 1 part of water reducing agent, 2 parts of waterproofing agent, 2 parts of redispersible latex powder, 2 parts of cellulose ether, 3 parts of graphite and 4 parts of foaming agent;

[0056] Reinforcing fiber, in this embodiment, is 1 part of chopped glass fiber;

[0057] 15 parts of graphite polystyrene particles;

[0058] 50 parts of water.

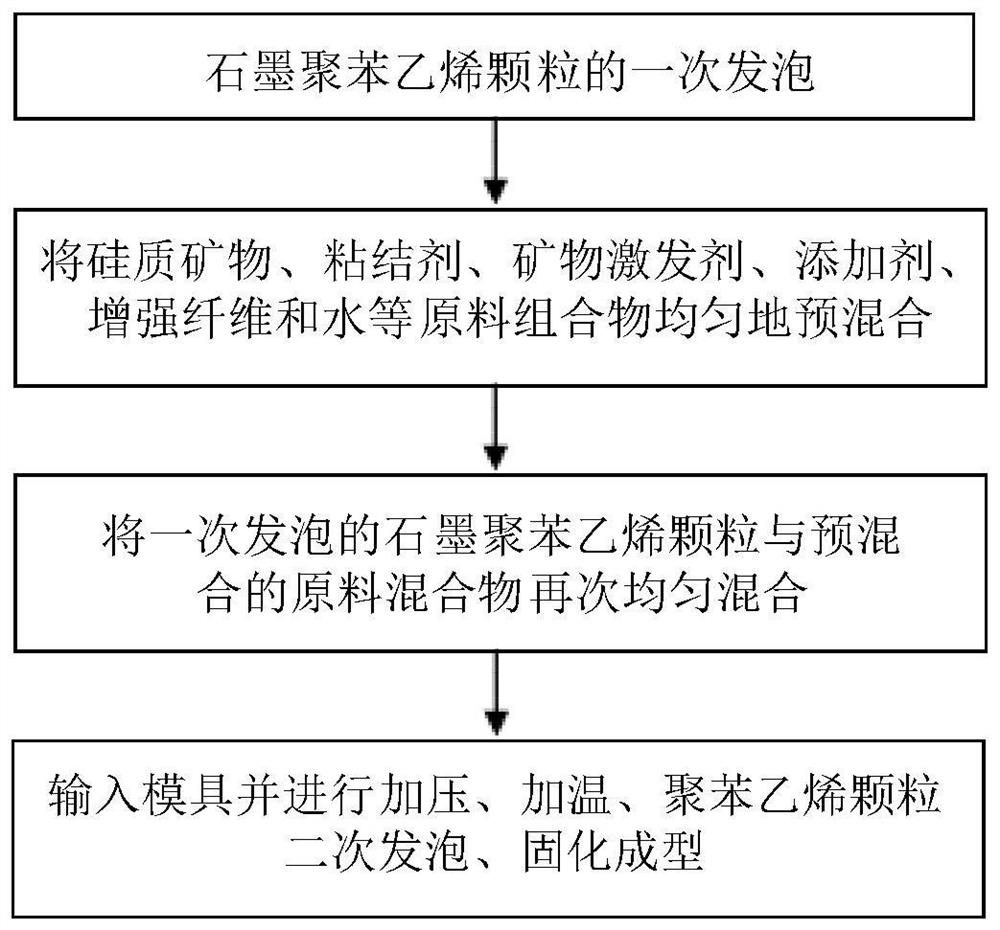

[0059] The manufacturing process of the flexible thermal insulation board of the present invention is as follows: image 3 As shown in the figure, first, the graphite polystyrene par...

Embodiment 2-5

[0067] The material ratios and production processes adopted in Examples 2-5 are basically the same as those in Example 1, except that in Examples 2, 3, 4 and 5, the temperatures applied to the raw material compositions during heating are respectively: 80°C, 95°C, 110°C and 130°C. The test results of the samples obtained in Examples 1-5 are shown in Table 1.

[0068]

Embodiment 6-10

[0070] The material ratio and manufacturing process used in Examples 6-10 are basically the same as those in Example 1, the difference is that in Examples 6, 7, 8, 9 and 10, the pressure is applied inside the raw material composition. The pressures of both are 0.15 MPa, and the temperatures applied inside the raw material composition during heating are 65°C, 80°C, 95°C, 110°C, and 130°C, respectively. The test results of the samples obtained in Examples 6-10 are shown in Table 2.

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com