Special sound insulation and heat insulation glass fiber composite material for aviation, and preparation method thereof

A composite material and glass fiber technology, applied in the direction of glass manufacturing equipment, manufacturing tools, etc., can solve the problems of heavy weight, failure to meet the use requirements, strength, installation processability, sound insulation performance and heat insulation effect defects, etc., to achieve uniform distribution, Increased production cost, excellent sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

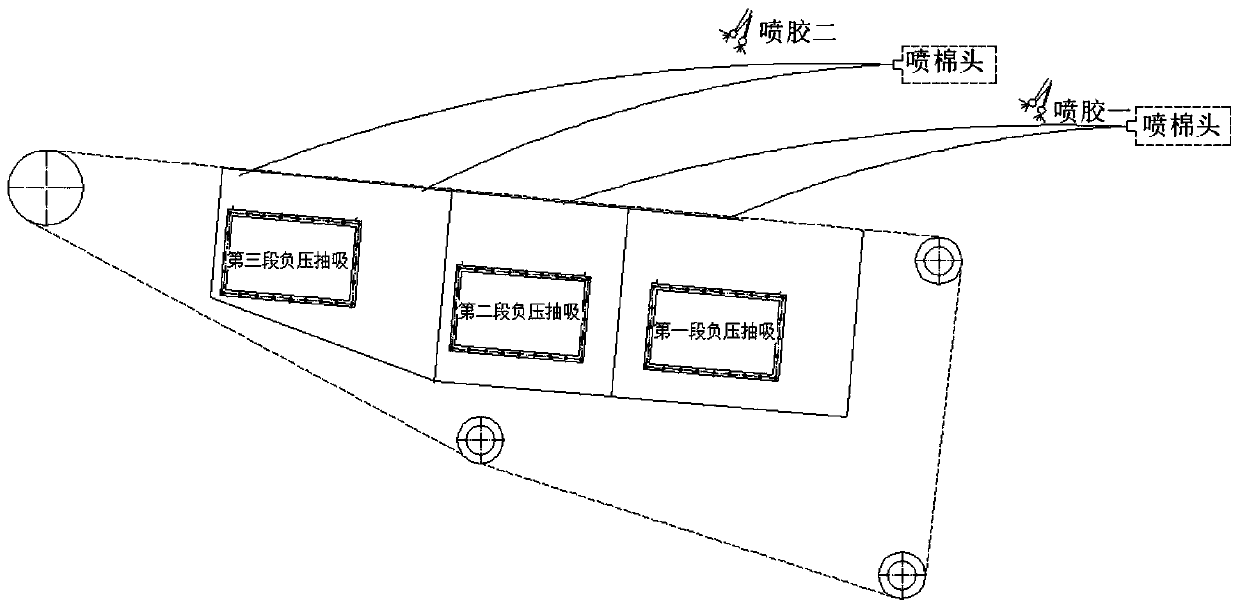

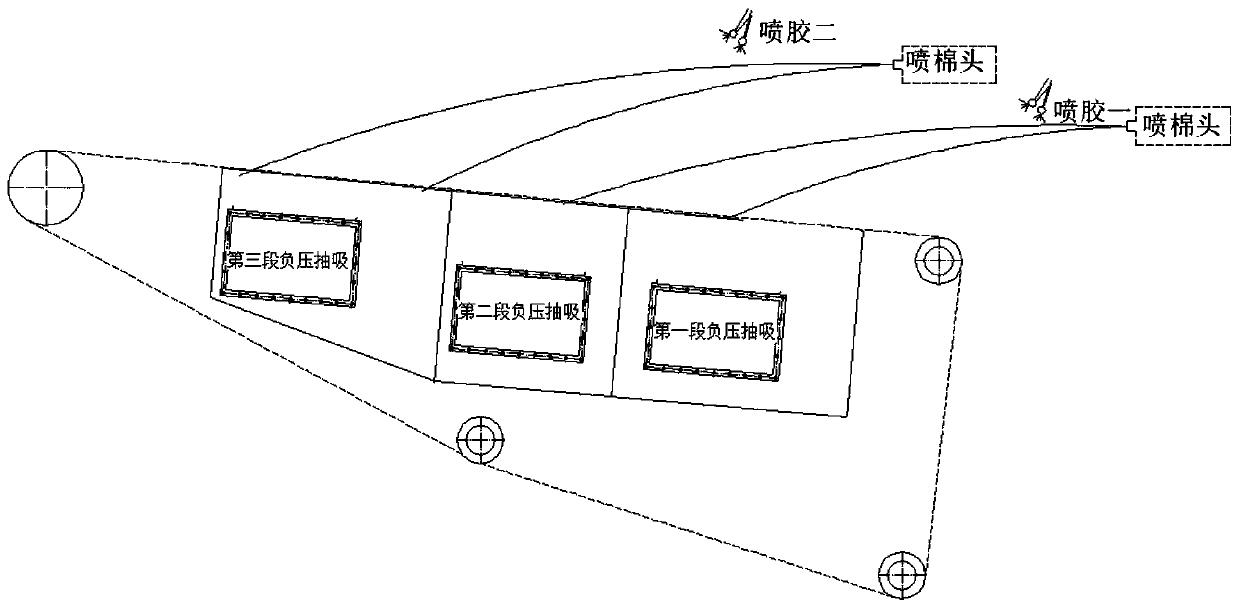

Method used

Image

Examples

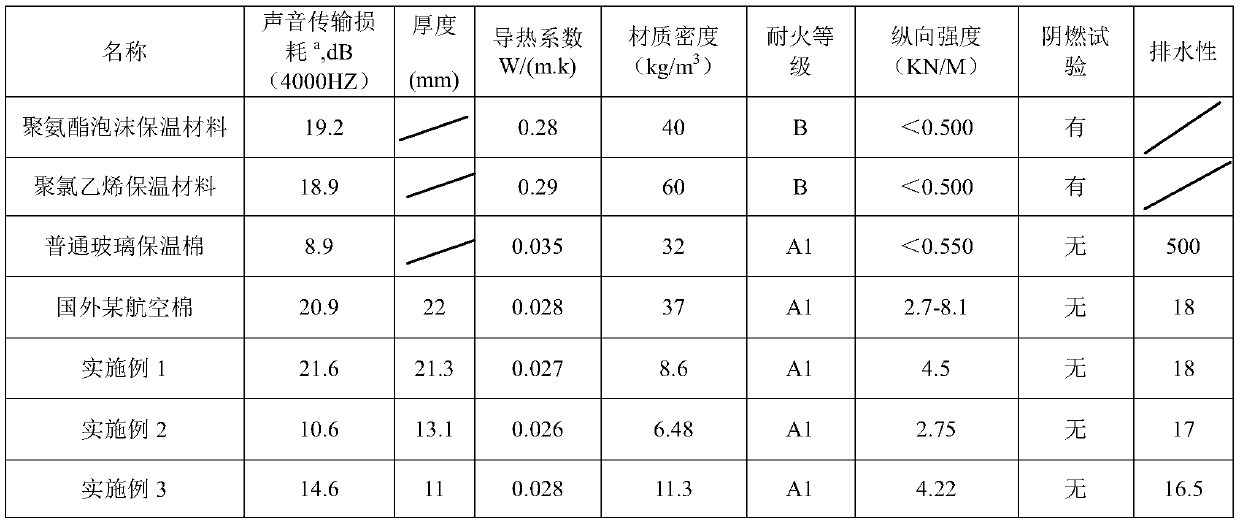

Embodiment 1

[0028] Aviation-specific sound-insulating and heat-insulating glass fiber composite material, by mass percentage, the composite material includes the following components: 78% glass fiber cotton, 22% composite resin, wherein the composite resin is composed of phenolic resin, organic fluorine resin and organic silicon resin Composition by mass ratio 3.5:0.1:0.2

[0029] (1) Raw material preparation: select 3.2 parts of zinc oxide, 14.3 parts of borax, 50.8 parts of quartz sand, 18.2 parts of potassium feldspar powder, 6.6 parts of soda ash, 3 parts of calcite, 1.1 parts of potassium carbonate and 2.8 parts of barium carbonate, mix them evenly and send them into The glass block is made after melting in the pool kiln at 1350°C;

[0030] (2) Secondary melting: the glass block prepared in step (1) is melted into molten glass again at 1050° C.;

[0031] (3) primary fiberization: the glass liquid in the step (2) flows out of the glass thin stream through the drain plate, and the gla...

Embodiment 2

[0036] Aviation-specific sound-insulating and heat-insulating glass fiber composite material, by mass percentage, the composite material includes the following components: 85% glass fiber cotton, 15% composite resin, wherein the composite resin is composed of phenolic resin, organic fluorine resin and organic silicon resin Composition by mass ratio 3.7:0.12:0.23

[0037] (1) Raw material preparation: select 8 parts of borax, 49.8 parts of quartz sand, 4.6 parts of potassium feldspar powder, 8.7 parts of albite feldspar, 16.3 parts of soda ash, 2.2 parts of calcite, 10 parts of dolomite, mix them evenly and send them into the kiln at 1420 Glass balls were obtained after melting at ℃;

[0038] (2) Secondary melting: the glass spheres prepared in step (1) are melted into molten glass again at 1100° C.;

[0039] (3) primary fiberization: the glass liquid in the step (2) flows out of the glass thin stream through the drain plate, and the glass thin stream is rapidly cooled and the...

Embodiment 3

[0044] Aviation-specific sound-insulating and heat-insulating glass fiber composite material, by mass percentage, the composite material includes the following components: 90% glass fiber cotton, 10% composite resin, wherein the composite resin is composed of phenolic resin, organic fluorine resin and organic silicon resin Composition by mass ratio 4:0.15:0.3

[0045] (1) Raw material preparation: select 3.2 parts of zinc oxide, 13.5 parts of borax, 51.6 parts of quartz sand, 18.2 parts of potassium feldspar powder, 0 parts of albite feldspar, 6.5 parts of soda ash, 3 parts of calcite, 1.2 parts of potassium carbonate and 2.8 parts of barium carbonate , mixed evenly and sent to the pool kiln to be melted at 1280°C to make glass block;

[0046] (2) Secondary melting: the glass block prepared in the step (1) is melted into molten glass again at 1050° C.;

[0047] (3) primary fiberization: the glass liquid in the step (2) flows out of the glass thin stream through the drain plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com