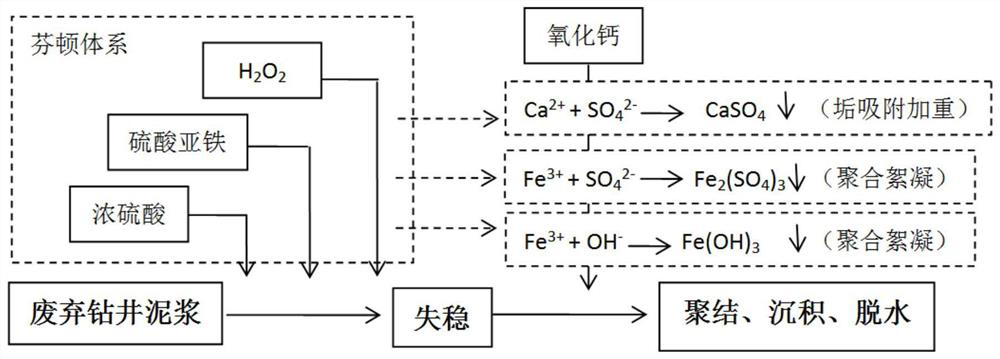

A dehydration method of waste drilling mud based on the coupling of Fenton's oxidation destabilization and scale adsorption aggravation

A technology of drilling mud and Fenton oxidation, which is applied in chemical instruments and methods, mining wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems that clay particles are not easy to sink and lose stability, and achieve pollutant reduction The effect of large capacity, short processing cycle and small processing site volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 1000mL of waste drilling mud (water content 65.25%, oil content 3.38%, solid content 31.37%), under constant stirring, first adjust its pH to 3 with concentrated sulfuric acid, then add 180mg ferrous sulfate, 3mL The hydrogen peroxide with a mass concentration of 30% was continuously stirred for 56 minutes, then calcium oxide was added to adjust the pH to 10, the stirring was stopped after 5 minutes, and centrifuged at 2500 r / min for 10 minutes. After treatment, the dehydration rate was 77.15%, the content of suspended matter in the extracted water was 35.21mg / L, the oil content was 2.19mg / L, and the COD was 215.71mg / L; the water content of the bottom sediment was 29.23%, and the oil content was 6.18%.

Embodiment 2

[0021] Take 1000mL of waste drilling mud (water content 45.78%, oil content 24.25%, solid content 29.97%), under constant speed stirring, first adjust its pH to 3 with concentrated sulfuric acid, then add 120mg ferrous sulfate, 120mg Vitamin C and 3mL hydrogen peroxide with a mass concentration of 30% were stirred continuously for 32 minutes, then calcium oxide was added to adjust the pH to 10, the stirring was stopped after 5 minutes, and centrifuged at 2500 r / min for 10 minutes. After treatment, the dehydration rate was 65.23%, the content of suspended matter in the extracted water was 68.79mg / L, the oil content was 17.51mg / L, and the COD was 247.08mg / L; the water content of the bottom sediment was 21.27%, and the oil content was 33.32%.

Embodiment 3

[0023] Take 1000mL of waste drilling mud (water content is 81.22%, oil content is 10.09%, solid content is 8.69%), under constant speed stirring, at first adjust its pH to be 3 with concentrated sulfuric acid, then add 120mg ferrous sulfate, 120mg Vitamin C and 3mL hydrogen peroxide with a mass concentration of 30% were continuously stirred for 29 minutes, then a mixture of calcium oxide and sodium hydroxide with a mass ratio of 1:1 was added to adjust the pH to 10, the stirring was stopped after 5 minutes, and centrifuged at 2500r / min for 10 minutes. After treatment, the dehydration rate is 91.37%, the content of suspended solids in the extracted water is 123.40mg / L, the oil content is 10.13mg / L, and the COD is 174.85mg / L; the water content of the bottom sediment is 27.91%, and the oil content is 37.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com