A self-distributing continuous die punching machine

A punching and self-dividing technology, which is applied in the field of self-dividing continuous die punching machines, can solve the problems of scratching hands of operators, inconvenient replacement, high labor intensity, etc., and achieve the effect of not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

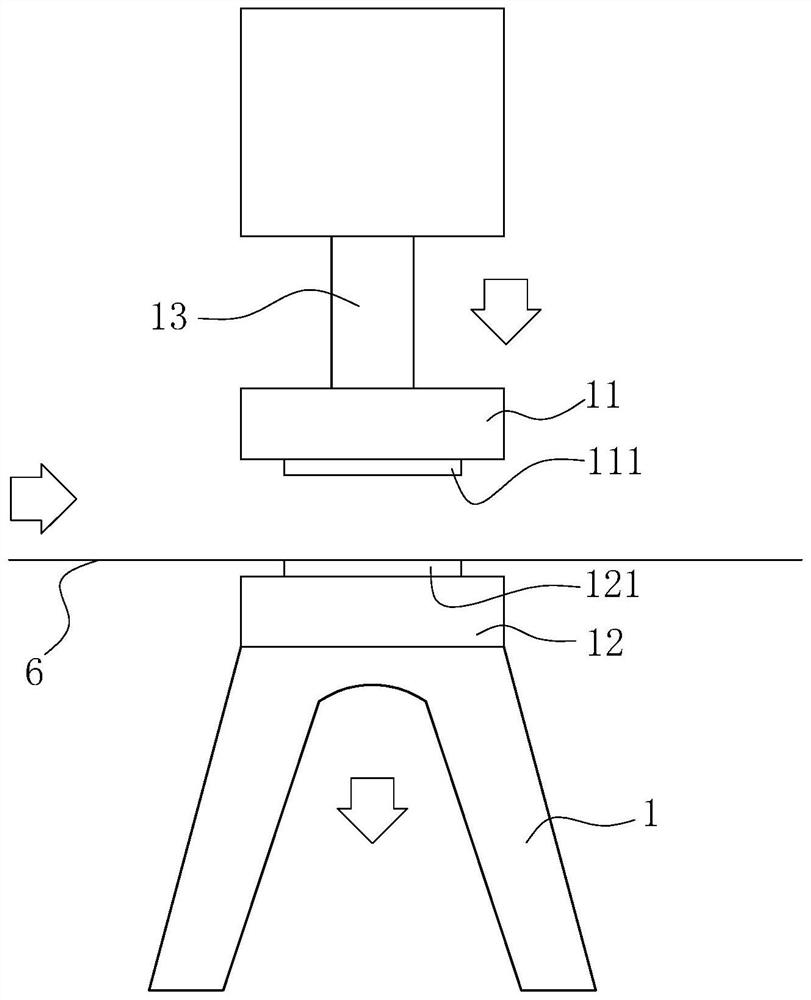

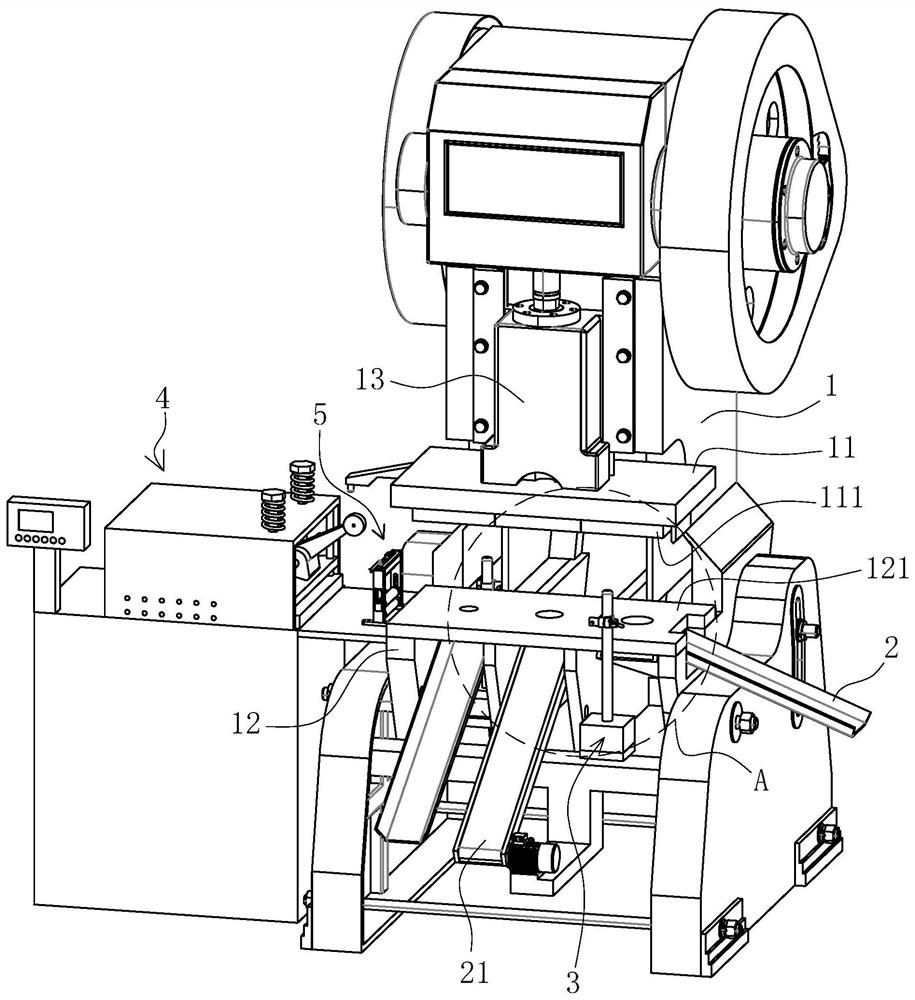

[0047] A self-distributing continuous die punching machine, refer to image 3 , which comprises a frame 1, on the frame 1, an upper mold frame 11 and a lower mold frame 12 are arranged oppositely, the upper mold frame 11 is provided with an upper mold 111, and the lower mold frame 12 is provided with a lower mold 121. The frame 1 is provided with a driving mechanism 13, and the driving mechanism 13 in this embodiment is the same as that of a mechanical punch press in the prior art. The upper mold frame 11 is connected to the driving mechanism 13, and can move up and down under the driving of the driving mechanism 13, so that the upper mold 111 and the lower mold 121 move closer or farther away from each other. It also includes a transfer mechanism 4 for transferring coils between the upper die 111 and the lower die 121 and a stamping oil adding device 5 located between the transfer mechanism 4 and the lower die 121 .

[0048] refer to image 3 and Figure 4 , the lower mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com