Anti-drop device of machine roomless car roof repairing platform

A machine room-less elevator and maintenance platform technology, applied in elevators, transportation and packaging, etc., can solve problems such as collision and failure to reset to the end, and achieve the effect of ensuring maintenance safety, changing the fixed mode, and facilitating installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

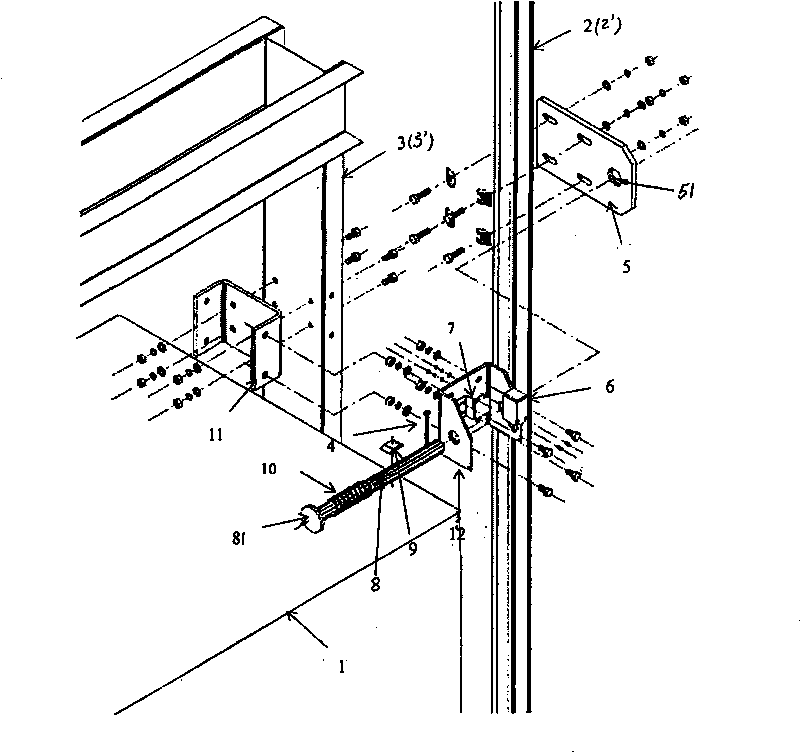

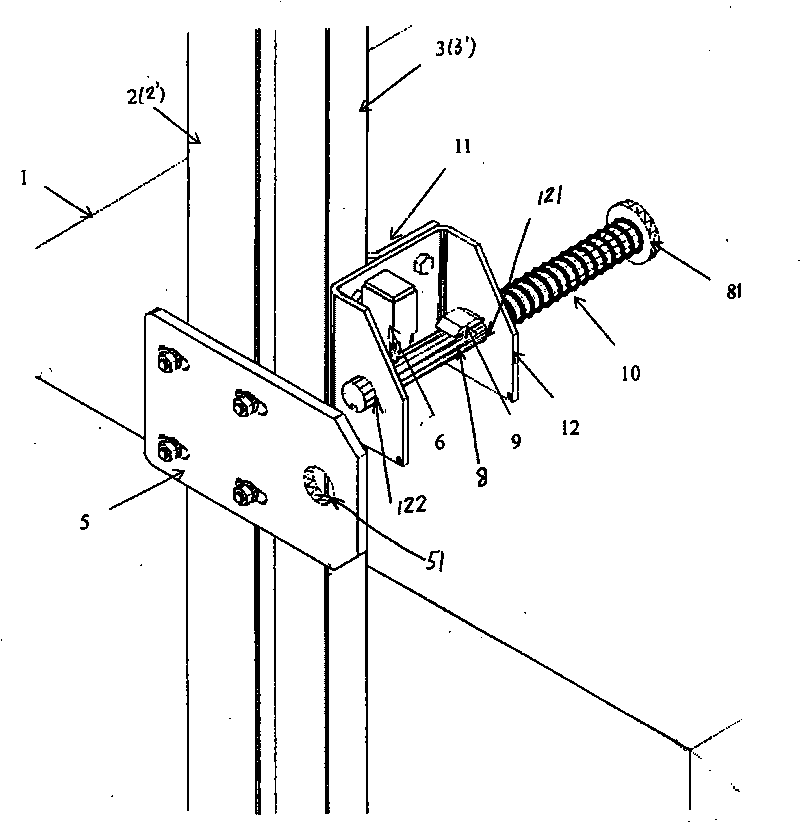

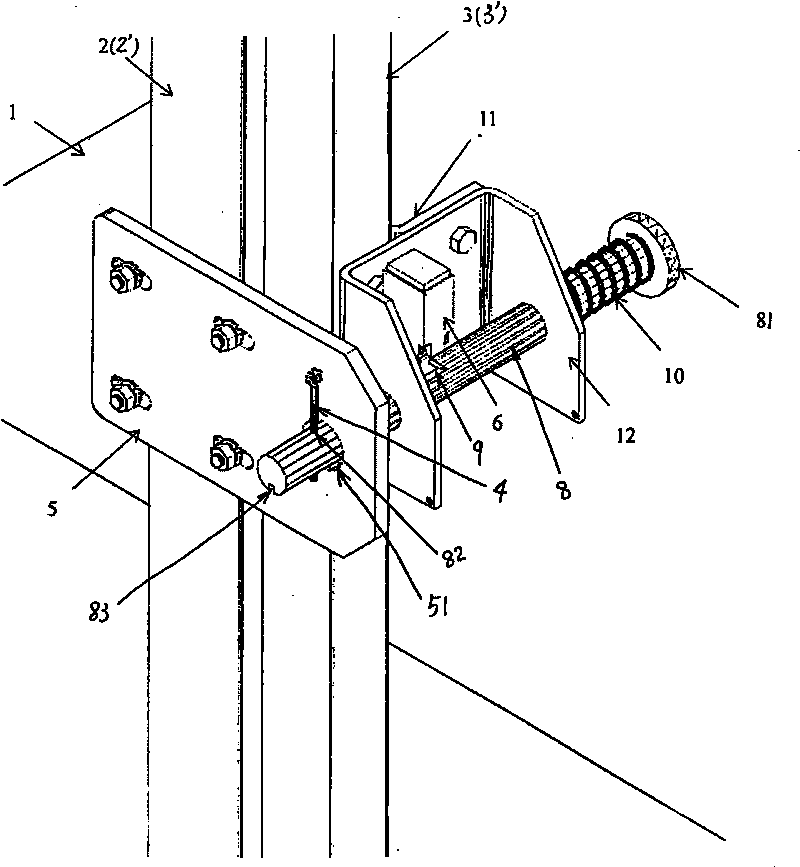

[0040] see figure 1 It is a schematic diagram of the disassembled and assembled structure of the anti-fall device of the present invention, figure 2 It is the schematic diagram of installation structure and image 3 As shown in the schematic diagram of the installation structure of the anti-falling device of the present invention in the maintenance state, a kind of anti-falling device for the maintenance platform of the machine-room-less elevator car is arranged on the top of the car 1, and the top of the elevator car is used as the maintenance platform, and the left and right sides of the car 1 There are vertical beams 3, 3' fixed on the side, and two relative guide rails 2, 2' are respectively arranged on the outside of the two vertical beams 3, 3', the car 1 moves up and down along the guide rails, and two anti-fall devices are arranged on the top of the car. On the relevant vertical beams 3, 3', where,

[0041] The anti-fall device comprises a fixed seat 11, an anti-fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com