Electric power maintenance ladder capable of verifying live parts

A technology for maintenance ladders and electricity inspection, applied in the directions of indicating the existence of current/voltage, lifting devices, lifting frames, etc., can solve the problems of maintenance ladder conduction, short circuit of electrical equipment, increased workload, etc., to achieve safe and reliable use, system The effect of stable signal and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

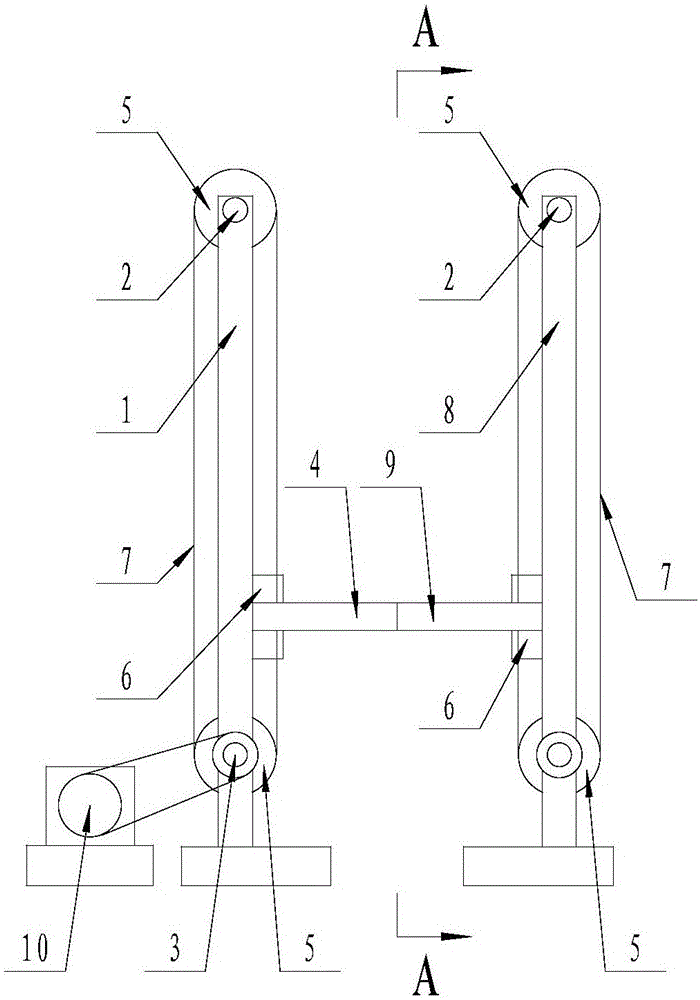

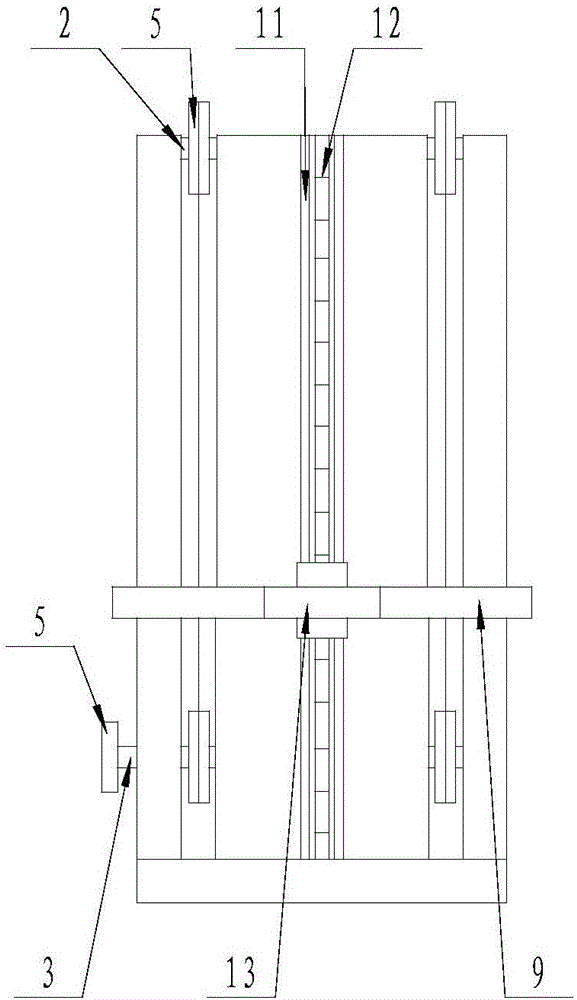

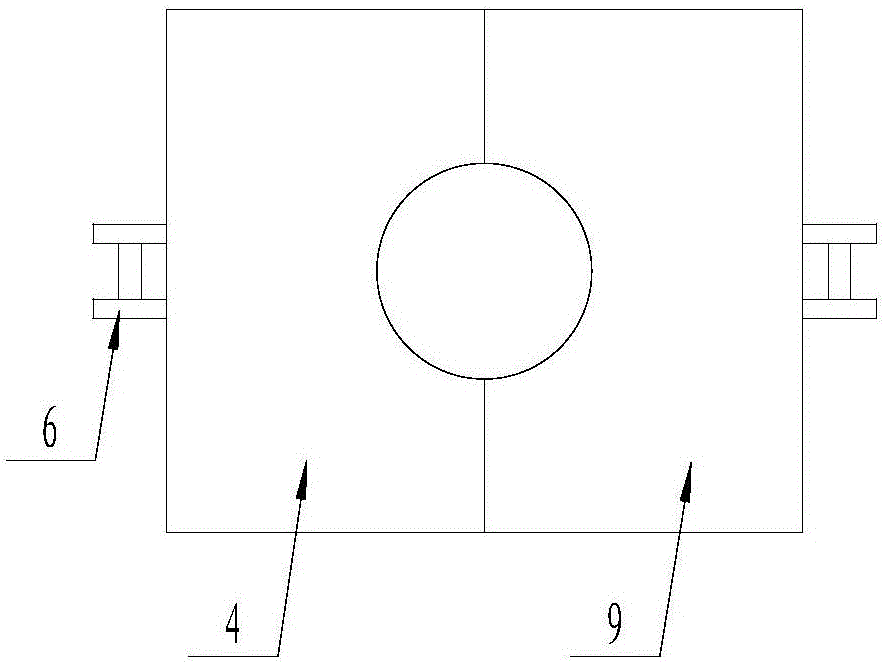

[0028] Such as figure 1 , figure 2 As shown, a kind of electric inspection and maintenance ladder comprises a first lifting frame 1 and a second lifting frame 8, the first lifting frame 1 and the second lifting frame 8 are respectively provided with a lifting transmission mechanism, the first lifting frame 1 and the second lifting frame The lifting transmission mechanisms of the two lifting frames 8 are respectively connected with the first lifting platform 4 and the second lifting platform 9, and the first lifting platform 4 and the second lifting platform 9 are detachably connected. The first lifting frame 1 and the second lifting frame 8 can be used alone or in combination. It is flexible and convenient to use alone, and is suitable for single-person work. The combined use has a wide range of work, is safer and more reliable, and is suitable for multi-person work. The first lifting The tops of the frame 1 and the second elevating frame 8 are provided with a non-contact el...

Embodiment 2

[0030] Such as Figure 5 As shown, the non-contact electrometric device includes a power supply, a single-chip microcomputer, a sensor, a signal processing module, a voice module, and an indicating module. The sensor is used to read the electric field signal and transmit the signal to the signal processing module. The signal processing module includes a parallel Two identical signal processing circuits, the single-chip microcomputer is used to receive the signal from the signal processing module, and the single-chip microcomputer will make a corresponding judgment, and send the processing result to the subsequent circuit, and the voice module and the indication module are connected with the single-chip microcomputer. The signal processing module is a two-way crossover operation circuit, the two signal processing circuits are completely consistent, and the cross-check is performed before sending the signal to the indicator light and the computer at the end, that is, only when th...

Embodiment 3

[0034] The lifting transmission mechanism includes a motor 10, a transmission shaft 3 and a driven shaft 2, and the transmission shaft 3 and the driven shaft 2 are respectively fixed with at least one group of sprockets 5, and the chain wheels 5 of the transmission shaft 3 and the driven shaft 2 The sprocket 5 is arranged vertically correspondingly and is connected by a chain 7 , and one end of the transmission rotating shaft 3 is also connected with the motor 10 by the sprocket 5 and the chain 7 . The structure of the lifting transmission mechanism is not limited to the above-mentioned structure, and other structures similar to the present application can also be used, such as gear transmission, hydraulic lifting and other structures.

[0035] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com