Large-scale press processing system for transmission oil seal processing

A technology for stamping and transmission oil, applied in the field of stamping equipment, can solve the problems of increasing the time for changing coils and feeding materials, limiting the processing efficiency, etc., and achieves the effect of stable transmission and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

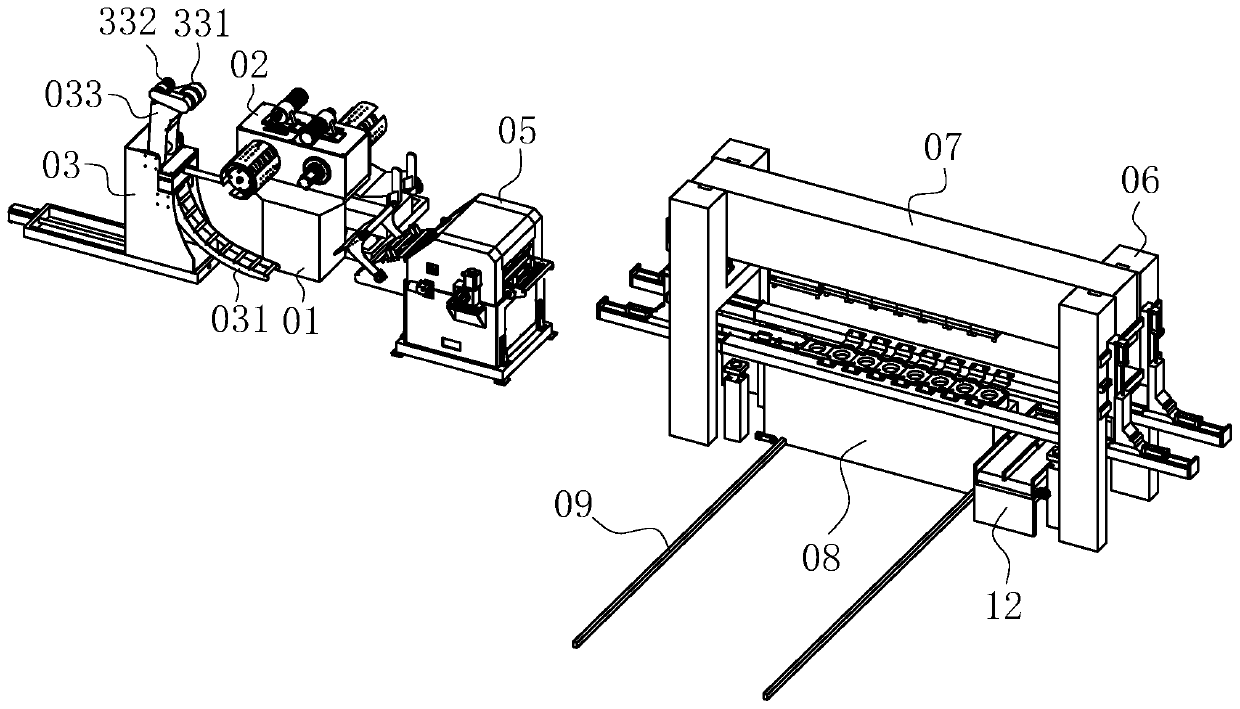

[0060] A large-scale stamping processing system for gearbox oil seal processing, refer to figure 1 , It includes a strip unwinding unit, a strip orthopedic unit and a stamping forming unit arranged in sequence according to the running direction of the strip. When used for the punching of gearbox oil seals, the metal coil used as the raw material is fixed to the strip unwinding unit and slowly unwinded; the unwinded strip is straightened and flattened by the strip orthopedic unit and then transferred to the stamping forming Unit; Finally, the strip material completes the process steps of dropping wafers, stretching, forming, shaping, punching, turning, punching and trimming at the stamping forming unit to obtain stamping parts.

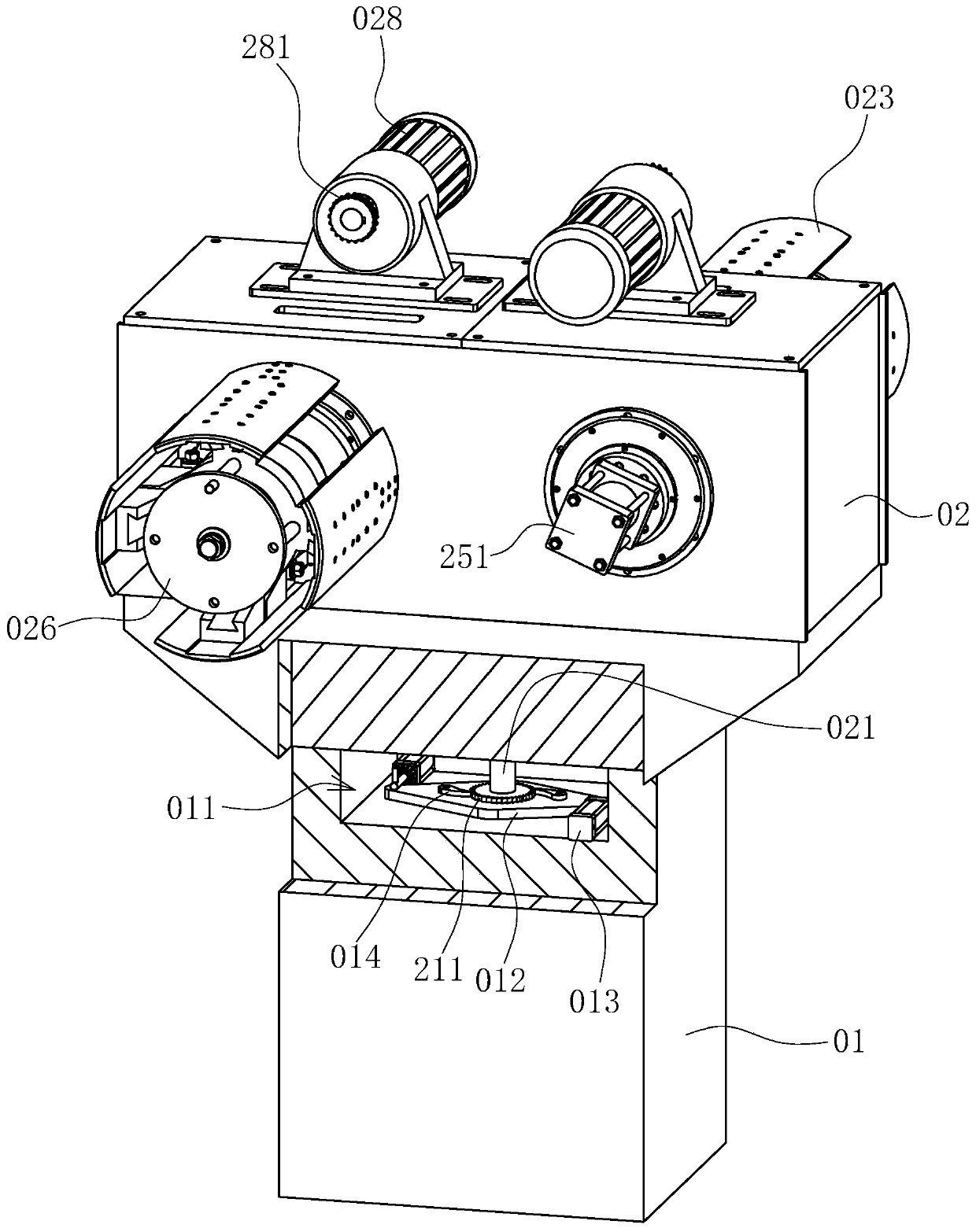

[0061] Reference figure 1 with figure 2 , The strip unwinding unit includes a base 01, a rotating table 02 arranged above the base 01, a material guide 03 and a material roll lifting device. The rotating table 02 is provided with a roll fixing device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com