A kind of gallium oxide nano material transfer method

A technology of nanomaterials and transfer methods, which is applied in the field of separation of nanomaterials to achieve good separation effect, simple operation and high success rate of transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

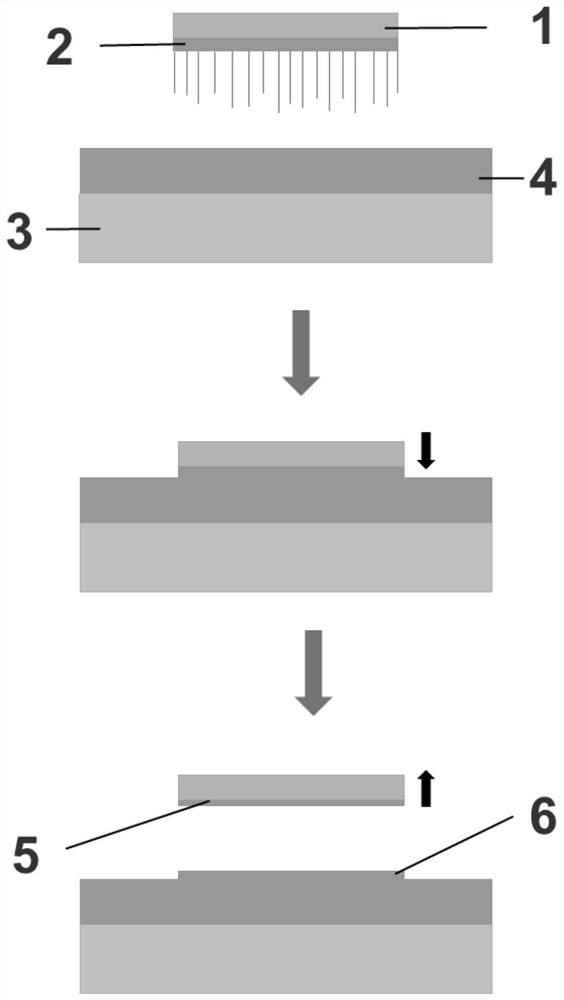

[0033] Example 1: Method for transferring gallium oxide nano.

[0034] The steps are as follows:

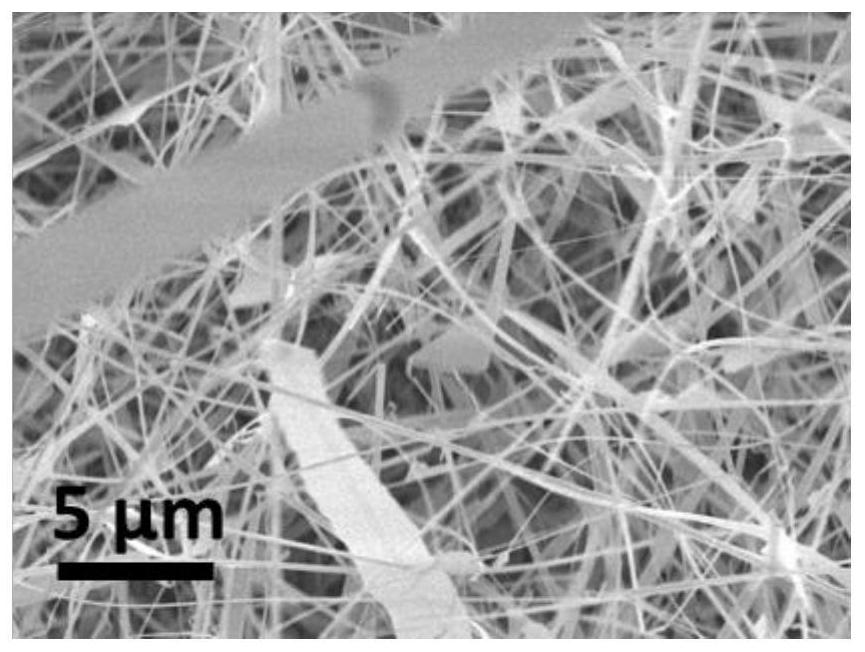

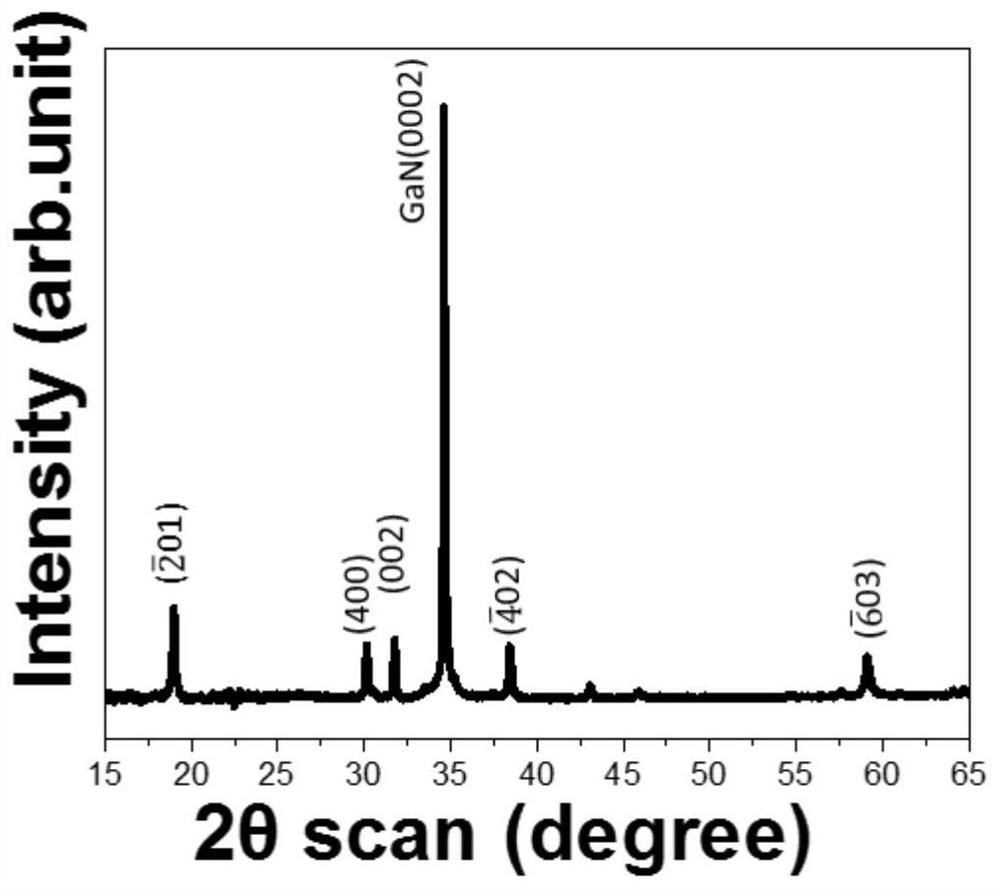

[0035] (1) A (0001) gallium nitride film is a substrate, an area of 2 mm × 2 mm, and a thickness of 20 μm, and a CVD method is generated on a gallium nitride film substrate to grow β-gallium oxide nanomaterials.

[0036] (2) Use polysilicon as a substrate material, deposit a layer of SiO on substrate material 2 The dielectric layer is to increase the adhesion between the gallium oxide material and the substrate and the insulation effect. SiO 2 The dielectric layer thickness is 200 nm.

[0037] (3) Put the growth of beta-gallium oxide nanomaterials, and use non-mechanical way to apply a specific force, that is, SiO 2 At 1cm height above the dielectric layer, the restriction is released, so that the β-gallium oxide nanomaterial layer naturally drops naturally due to gravity, bonded to SiO under the influence of gravity. 2 Medium layer.

[0038] (4) After the bonding, then the SIO 2 T...

Embodiment 2

[0040] Example 2: A method of transferring gallium oxide nanoji.

[0041] The steps are as follows:

[0042] (1) A (0001) gallium nitride film is a substrate, an area of 2 mm × 2 mm, and a thickness of 20 μm, and a CVD method is generated on a gallium nitride film substrate to grow β-gallium oxide nanomaterials.

[0043] (2) Use polysilicon as a substrate material, deposit a layer of SiO on substrate material 2 The dielectric layer is to increase the adhesion between the gallium oxide material and the substrate and the insulation effect. SiO 2 The dielectric layer thickness is 200 nm.

[0044] (3) The growth of the β-gallium oxide nanomaterial layer is facing downward, and the mechanical manner is applied, and the β-gallium oxide nanomaterial layer is placed in SiO. 2 On the dielectric layer, the β-gallium oxide nanomaterial layer was pressed using 0.1 N to press the β-gallium oxide nanomaterial layer in SiO. 2 Medium layer.

[0045] (4) After the bonding, then the SIO 2 The die...

Embodiment 3

[0049] Example 3: A method of transferring gallium oxide nanowires.

[0050] The steps are as follows:

[0051] (1) A (0001) gallium nitride film is a substrate, an area of 2 mm × 2 mm, and a thickness of 20 μm, and a CVD method is generated on a gallium nitride film substrate to grow β-gallium oxide nanomaterials.

[0052] (2) Use polysilicon as a substrate material, deposit a layer of SiO on substrate material 2 The dielectric layer is to increase the adhesion between the gallium oxide material and the substrate and the insulation effect. SiO 2The dielectric layer thickness is 200 nm.

[0053] (3) The growth of the β-gallium oxide nanomaterial layer is facing downward, and the mechanical manner is applied, and the β-gallium oxide nanomaterial layer is placed in SiO. 2 On the dielectric layer, the β-gallium oxide nanomaterial layer was pressed using 0.1 N to press the β-gallium oxide nanomaterial layer in SiO. 2 Medium layer.

[0054] (4) After the bonding, then the SIO 2 The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com