Preparation method of flexible film pressure sensor

A pressure sensor, flexible film technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problem of small measuring range of the sensor, and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

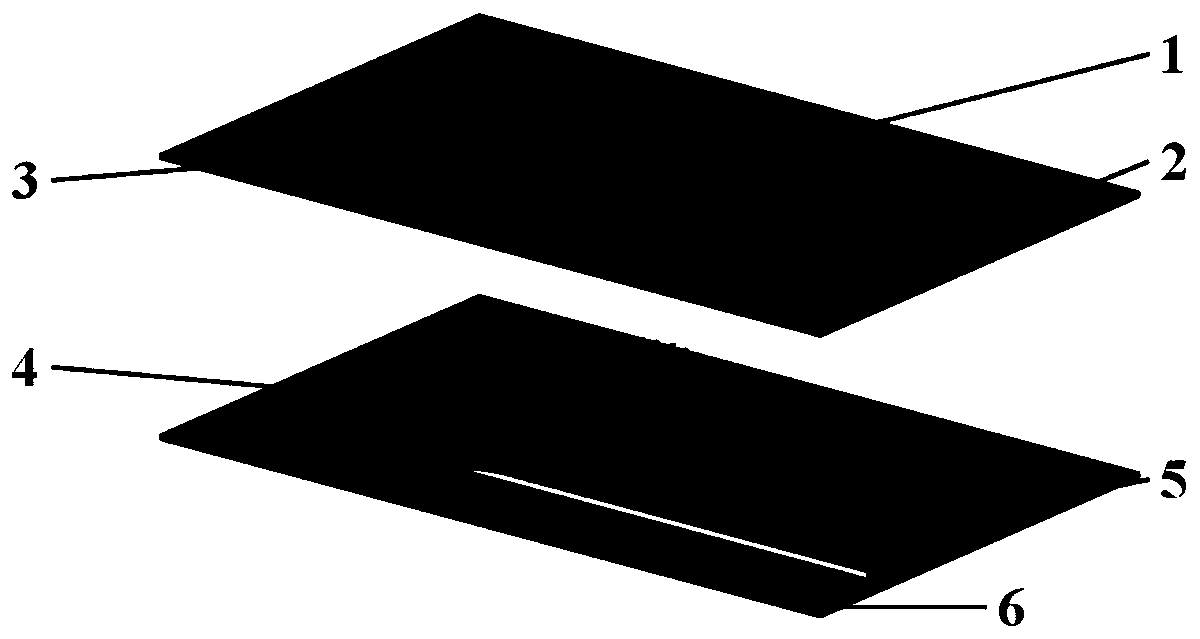

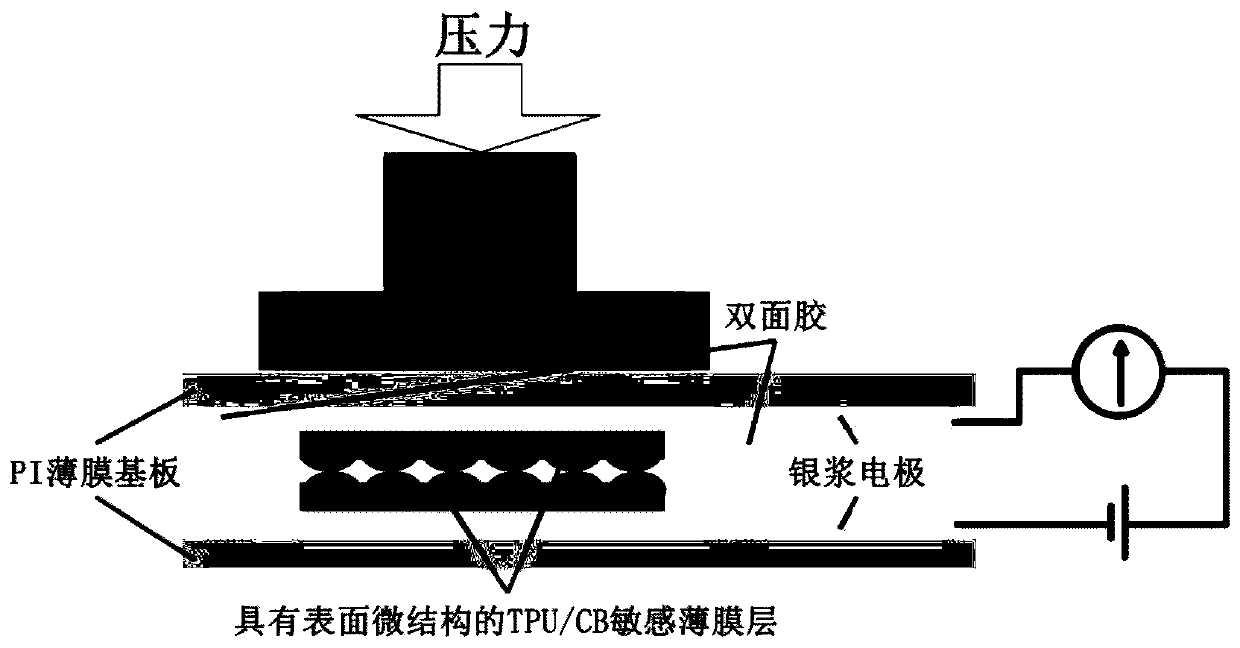

[0043] like figure 1 As shown, it is a structural schematic diagram of a flexible thin-film pressure sensor provided by the present invention. From top to bottom, it is an upper flexible substrate 1, an upper electrode layer 2, an upper sensitive thin-film layer 3, a lower sensitive thin-film layer 4, and a lower electrode layer 5. and the lower flexible substrate 6, wherein the upper and lower flexible substrates are PI (polyimide), the upper and lower electrode layers are silver electrodes, and the sensitive film layer is TPU (thermoplastic polyurethane), Carbon Black (conductive carbon black), DMAc (Dimethylacetamide) and dibutyl phthalate are uniformly mixed to make a composite material layer.

[0044] The preparation method of the above-mentioned flexible film pressure sensor specifically comprises the following steps:

[0045] Step 1: Take 0.45g of conductive carbon black and add it to 10g of DMAc (dimethylacetamide) solvent. At normal temperature and pressure, use an u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com