Comfortable permanent moisture absorption and quick drying polyester knitted fabric and making method thereof

A technology for moisture-absorbing and quick-drying, knitted fabrics, which is applied in knitting, weft-knitting, textile material processing, etc., can solve the problems of high cost of moisture-absorbing and perspiration-wicking additives, unsatisfactory moisture-absorbing and sweat-wicking effects, and decreased moisture-absorbing and sweat-wicking effects. , to achieve the effect of highlighting the function of moisture absorption and quick drying, changing the hand feel and improving the output of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for making a comfortable polyester permanent moisture-absorbing and quick-drying knitted fabric comprises the following steps:

[0057] Step 1, gray cloth weaving, by blending 65% microporous polyester fiber and 35% cotton fiber to fabricate polyester / cotton microporous mesh gray cloth, the texture of the gray cloth is a single-sided weft-knitted plain stitch structure, and the yarn length of the gray cloth is 29cm / 100G, gray fabric size is 196cm×280g / m 2 ;

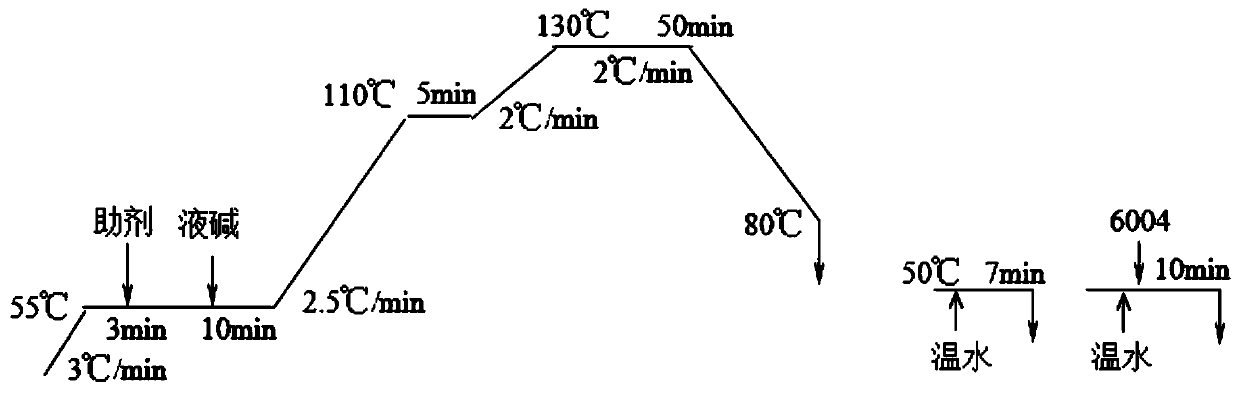

[0058] Step 2, pre-treatment one-bath treatment of opening holes: the microporous gray cloth is subjected to pre-treatment one-bath treatment of opening holes, and then washed with water and peracid; the pre-treatment one-bath treatment of opening holes is specifically: adding water, at 2°C / min The heating rate is raised to 50°C, followed by adding 1g / L refined degreasing agent SF-2 and 4g / L liquid caustic soda according to the water volume, keeping it warm for 15 minutes, then raising the temperature to...

Embodiment 2

[0069] A method for making a comfortable polyester permanent moisture-absorbing and quick-drying knitted fabric comprises the following steps:

[0070] Step 1, gray cloth weaving, by blending 65% microporous polyester fiber and 35% cotton fiber to fabricate polyester / cotton microporous mesh gray cloth, the texture of the gray cloth is a single-sided weft-knitted plain stitch structure, and the yarn length of the gray cloth is 29cm / 100G, gray fabric size is 196cm×280g / m 2 ;

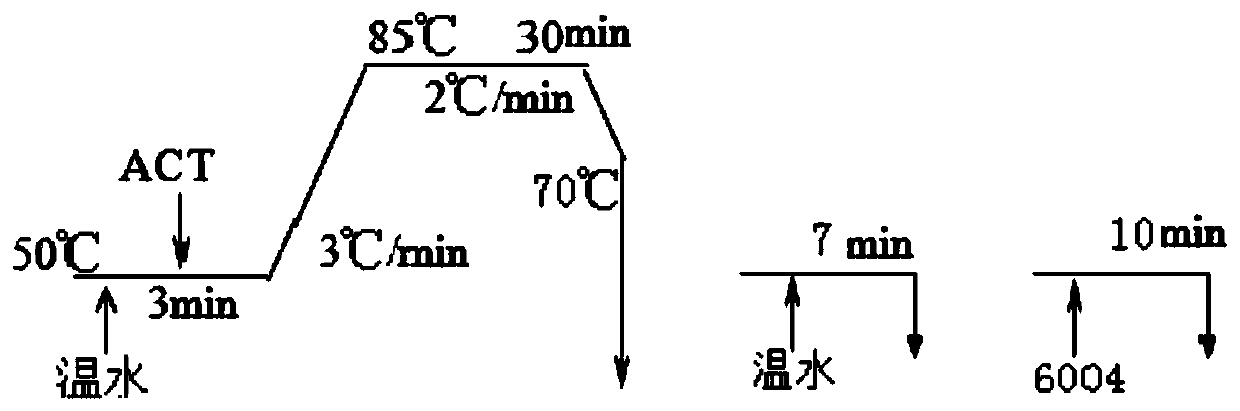

[0071] Step 2, pre-treatment one-bath treatment of opening holes: the microporous gray cloth is subjected to pre-treatment one-bath treatment of opening holes, and then washed with water and peracid; the pre-treatment one-bath treatment of opening holes is specifically: adding water, at 4°C / min The heating rate is raised to 60°C, followed by adding 2.5g / L refined degreasing agent SF-2 and 12g / L liquid caustic soda according to the water volume, and the temperature is raised to 115°C at a heating rate of ...

Embodiment 3

[0082] A method for making a comfortable polyester permanent moisture-absorbing and quick-drying knitted fabric comprises the following steps:

[0083] Step 1, gray cloth weaving, by blending 65% microporous polyester fiber and 35% cotton fiber to fabricate polyester / cotton microporous mesh gray cloth, the texture of the gray cloth is a single-sided weft-knitted plain stitch structure, and the yarn length of the gray cloth is 29cm / 100G, gray fabric size is 196cm×280g / m 2 ;

[0084] The arrangement of weaving triangles is shown in Table 1 below:

[0085] Table 1 Weaving triangle arrangement

[0086] dial

∧

∧

∧

∩

Number of channels / F

1

2

3

4

∧

∩

∧

∧

[0087] ∧: Triangle forming circle ∩: Triangle tucking

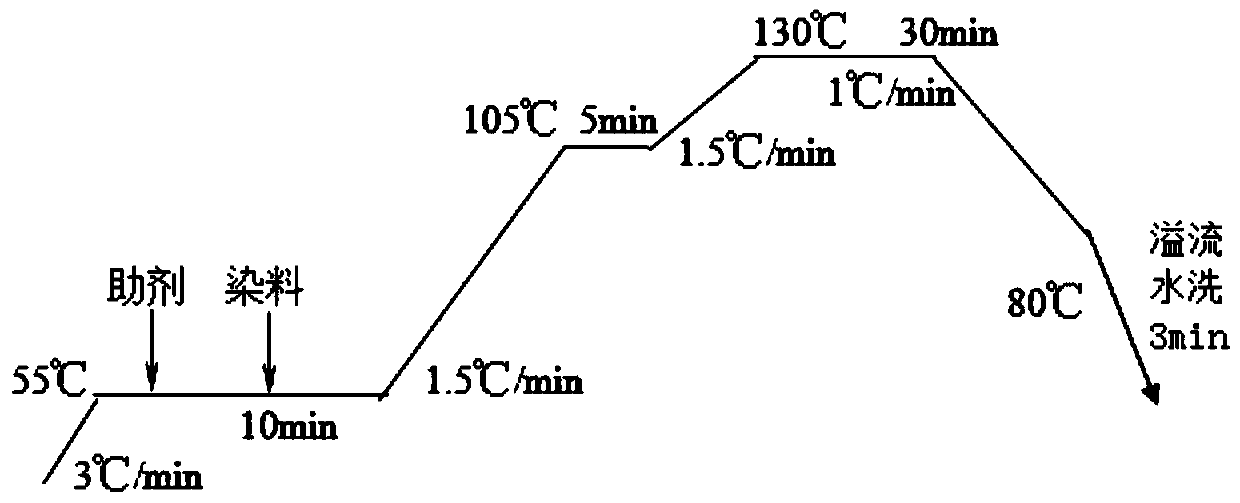

[0088] Step 2, pre-treatment one-bath treatment of opening holes: pre-treatment one-bath treatment of opening holes on the microporous gray cloth, and then washing with water and peracid; the pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com