High-strength aluminum alloy section bar for battery tray of novel energy vehicle and preparation method for high-strength aluminum alloy section bar

A technology for new energy vehicles and aluminum alloy profiles, which is applied in the field of high-strength aluminum alloy profiles for new energy vehicle battery trays and its preparation. It can solve problems affecting the quality of new energy vehicles, low strength of aluminum alloy profiles, and short service life. The performance deviation is small, the product quality is improved, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

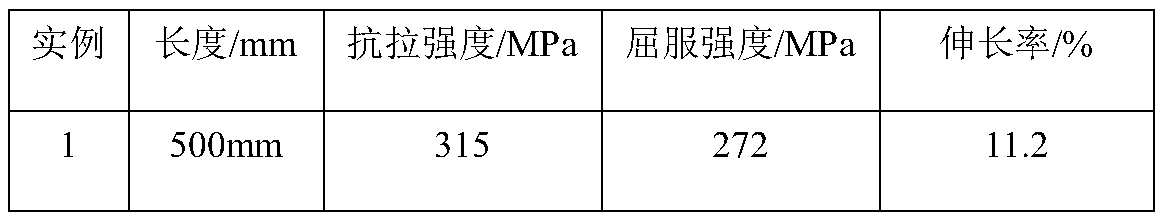

Embodiment 1

[0028] The invention relates to a high-strength aluminum alloy profile for a new energy vehicle battery tray. The chemical composition of the aluminum alloy is Mg: 0.95%, Si: 0.70%, Cu: 0.22%, Mn: 0.08%, Cr: 0.08%. Ti: 0.008%, Fe: 0%, Zn: 0%, Zr: 0.02%, and the balance is Al. The main preparation process of this aluminum alloy profile is as follows:

[0029] The main production process includes: casting - homogenization - cooling - extrusion - stretching - aging, the specific operations are as follows:

[0030] (1) Melting and casting: Add the prepared raw materials into the melting furnace for melting according to the process requirements, and effectively remove the impurities and gases in the melt by means of degassing and slag removal refining, and pass the smelted molten aluminum through the deep well casting system Cooling and casting into aluminum alloy ingots;

[0031] (2) Homogenization: place the aluminum alloy ingot at 568°C for high-temperature homogenization treat...

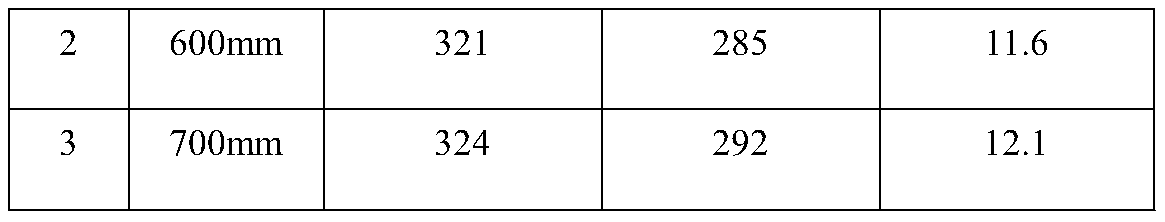

Embodiment 2

[0037] The invention relates to a high-strength aluminum alloy profile for a new energy vehicle battery tray. The chemical composition of the aluminum alloy is Mg: 1.02%, Si: 0.72%, Cu: 0.25%, Mn: 0.11%, Cr: 0.9%, Ti: 0.010%, Fe: 0.08%, Zn: 0.024%, Zr: 0.035%, and the balance is Al. The main preparation process of this aluminum alloy profile is as follows:

[0038] The main production process includes: casting - homogenization - cooling - extrusion - stretching - aging, the specific operations are as follows:

[0039] (1) Melting and casting: Add the prepared raw materials into the melting furnace for melting according to the process requirements, and effectively remove the impurities and gases in the melt by means of degassing and slag removal refining, and pass the smelted molten aluminum through the deep well casting system Cooling and casting into aluminum alloy ingots;

[0040] (2) Homogenization: place the aluminum alloy ingot at 572°C for high-temperature homogenizatio...

Embodiment 3

[0046] The invention relates to a high-strength aluminum alloy profile for a new energy automobile battery tray. The chemical composition of the aluminum alloy is Mg: 1.06%, Si: 0.75%, Cu: 0.30%, Mn: 0.13%, Cr: 0.11%. Ti: 0.012%, Fe: 0.18%, Zn: 0.05%, Zr: 0.05%, and the balance is Al. The main preparation process of this aluminum alloy profile is as follows:

[0047] The main production process includes: casting - homogenization - cooling - extrusion - stretching - aging, the specific operations are as follows:

[0048] (1) Melting and casting: Add the prepared raw materials into the melting furnace for melting according to the process requirements, and effectively remove the impurities and gases in the melt by means of degassing and slag removal refining, and pass the smelted molten aluminum through the deep well casting system Cooling and casting into aluminum alloy ingots;

[0049] (2) Homogenization: place the aluminum alloy ingot at 574°C for high-temperature homogenizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com