A general method for the assembly of ultrathin porous nanosheets using metal oxide quantum dots

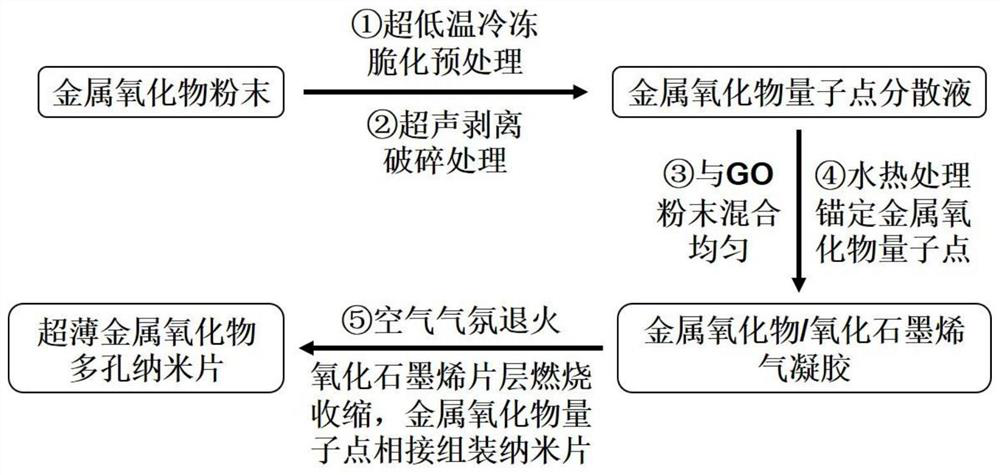

A general method and oxide technology, applied in nanotechnology, cobalt oxide/cobalt hydroxide, nickel oxide/nickel hydroxide, etc., can solve the problems of difficult and ultra-thin porous layer flaky nanomaterials, and achieve uniform pore distribution, The effect of stable morphology and less demand for raw materials and equipment types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

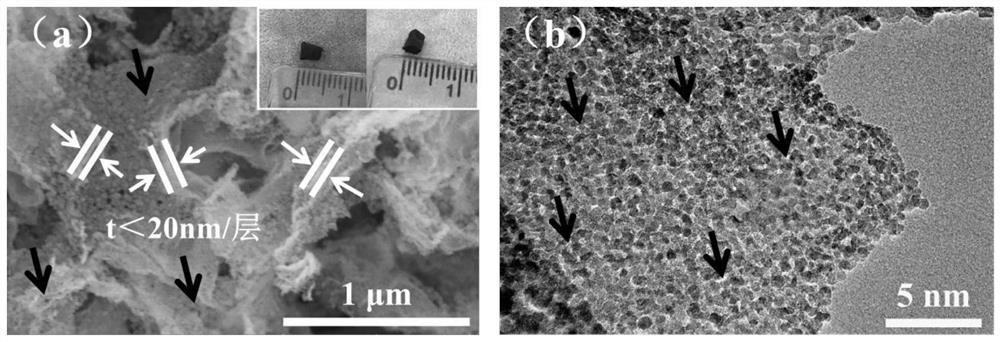

[0033] This embodiment prepares CO as follows 3 O 4 Porous nanoflakes:

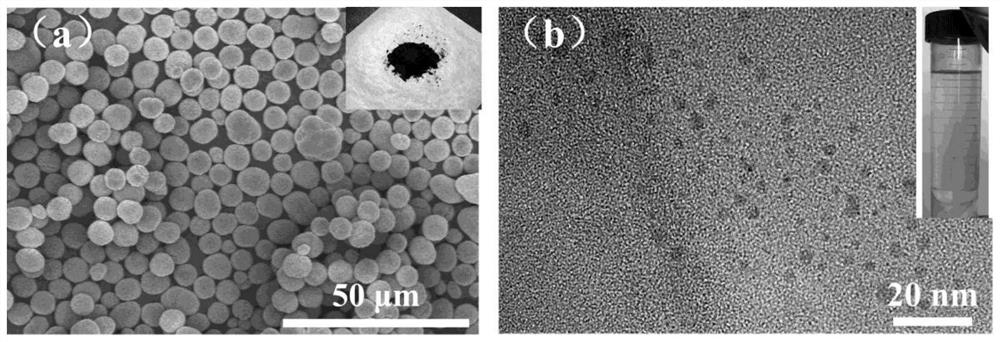

[0034] 1) Weigh 2G CO 3 O 4 The initial powder (purchased from the ALO) was placed in a 50 ml centrifuge tube, and then 40 ml of liquid nitrogen was injected into the centrifuge tube, and the centrifuge tube was immersed in the thermos of liquid nitrogen for 12 hours, thereby completing ultra-low temperature cold frit. Pretreatment;

[0035] 2) Remove the centrifuge tube of step 1), after the liquid is completely volatilized, then the powder is immediately dispersed in a mixed solvent of 500 ml of isopropanol and a water volume ratio of 1: 1, and the ultrasonic power ultrasound is broken. Treatment 10 hours, then centrifuge at 10,000 rpm for 5min, take the upper layer, to produce CO 3 O 4 Quantum dispersion;

[0036] 3) at 500ml CO 3 O 4 The quantum dot dispersion was added to 15 mg of oxide powder, and the ultrasonic dispersion was uniformly dispersed, and the heat treatment was 12 h at 180 ° C to obtain CO. ...

Embodiment 2

[0040] This embodiment prepares CO as follows 3 O 4 Porous nanoflakes:

[0041] 1) Weigh 1G CO 3 O 4 The initial powder (purchased from the ALO) was placed in a 50 ml centrifuge tube, and then 35 ml of liquid nitrogen was injected into the centrifuge tube, and the centrifuge tube was immersed in the thermos of liquid nitrogen for 14 hours, thereby completing ultra-low temperature cold frit. Pretreatment;

[0042] 2) Remove the centrifuge tube of step 1), after the liquid is completely volatilized, immediately after the treatment is dispersed in a 500 mL of 1-methyl-2-pyrrolidone solvent, and the crushing treatment is 8 hours by ultrasonic power of 300W, then 8000rpm Centrifuge 10min, take the upper layer, to make CO 3 O 4 Quantum dispersion;

[0043] 3) at 500ml CO 3 O 4 The quantum dot dispersion was added to 12 mg of oxide oxide powder, and the ultrasonic dispersion was uniformly dispersed, and the heat treatment was 180 ° C for 12 h, resulting in CO 3 O 4 / GO hydrogel;

[0044...

Embodiment 3

[0047] This embodiment prepares CO as follows 3 O 4 Porous nanoflakes:

[0048] 1) Weigh 0.1g Co 3 O 4 The initial powder (the powder preparation method is: 0.01 mol of hexahydrate and 0.01 mol urea is dissolved in 40 ml of deionized water, 150 ° C water heat treatment for 5 h, the resulting powder 500 ° C air annealing 3h is given into 50 ml of centrifuge tube In the centrifuge tube, 40 ml of liquid nitrogen was then injected into the centrifuge tube, and the centrifuge tube was immersed in the insulation tub in liquid nitrogen, thereby completing ultra-low temperature freezing and criticization pretreatment;

[0049] 2) Remove the centrifuge tube of step 1), after the liquid is completely volatilized, the treatment is immediately dispersed in a mixed solvent of 100 ml of isopropanol and a water volume ratio of 1: 1, and the ultrasonic power is ultrasound. Handling 6 hours, then 6000 rpm is centrifuged for 20min, take the upper layer, and produce CO 3 O 4 Quantum dispersion;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com