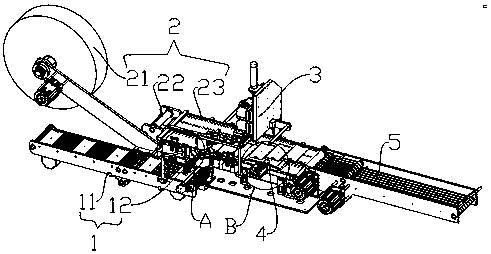

An all-in-one machine for automatic edge banding production of screen protection products

A protective product and all-in-one technology, applied in packaging sealing/fastening, transportation packaging, packaging, etc., can solve the problems of no continuous packaging, uneven packaging quality, low degree of automation, etc., and achieve good market application value , Improve production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] Embodiment 2: The ironing cloth receiving support bar 38 is connected by a cloth ironing motor, the cloth ironing motor is fixed on the back of the backboard, and the output shaft of the ironing cloth motor is fixed with a driving synchronous wheel, and the cloth ironing motor is fixed on the output shaft of the ironing cloth receiving material. A driven synchronous wheel is set on the support rod 38, and the active synchronous wheel and the driven synchronous wheel are connected by a synchronous belt, and the ironing motor drives the ironing material receiving support bar 38 to rotate intermittently through the synchronous belt, so that the ironing cloth can be used for a period of time automatically turn the position.

Embodiment 3

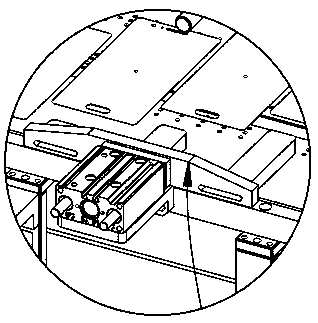

[0052] The third embodiment is different from the above embodiments in that a hot-pressing backing plate 27 is arranged directly below the hot-cutting seat 36, and the two ends of the hot-pressing backing plate 27 are fixed on the frames on both sides of the bag film conveyor belt 23, The bag film conveyor belt 23 passes under the heat pressing backing plate 27, and the height of the upper surface of the hot pressing backing plate 27 is flush with the overall height of the bag film conveyor belt 23, and the hot pressing backing plate 27 provides a padding function for the hot cutter 361 on the hot pressing seat , using a hot knife 361 to cut off the bag film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com