Double-chuck mechanism for automatic clamping and fusing of wrapping film

An automatic clamping and stretching film technology, applied in the direction of packaging/bundling items, packaging, wrapping items, etc., can solve the problems of shortening the service life of motors, wasting power, and non-adjustable packaging speed, and achieve continuous packaging and improve packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

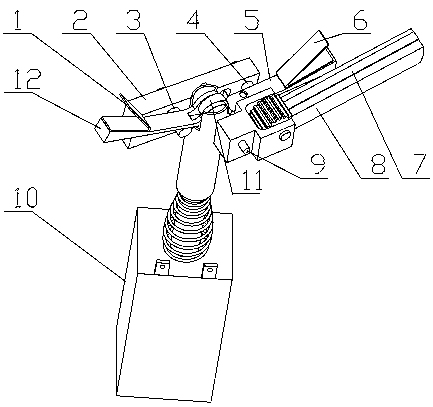

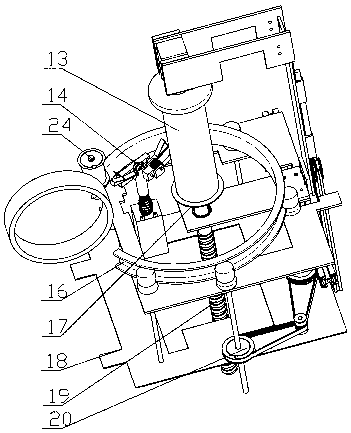

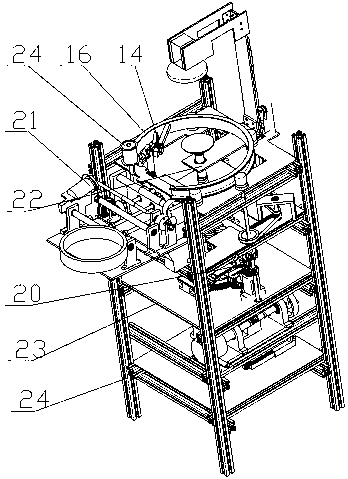

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 , when it is necessary to wrap the packaged goods 13, the mechanism moves down the clips on both sides (the right clip 5 and the left clip 12) through the pull-down of the push-pull electromagnet 10, and the left clip 12 and the right clip 5 respectively The left guide pin 3 and the right guide pin 4 are guided to rotate around the rotating pin 9, and gradually move closer to the middle during the downward movement, and drive the left spring piece 1 and the right spring piece 6 to clamp the wrapping film 15, to be wound After the film 15 is wrapped one to two times and firmly attached to the packaged product 13, the push-pull electromagnet 10 is powered off and resets, driving the left clip 12 and the right clip 5 to rise, and the left clip 12 and the right clip are driven up by the torsion spring 11. The upper clip 5 rotates around the rotating pin 9 and resets to a nearly horizontal state. If it is not reset to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com