Friction stir welding method of cold-sprayed Ti coating assisted aluminium-steel dissimilar metal lap joint

A technology of friction stir welding and dissimilar metals, applied in the direction of metal processing equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of IMCs, thermal cracks, etc., achieve simple spraying and welding process, prevent direct contact reaction, Easy to automate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the above-mentioned optimized process parameters, but the present invention is not limited thereby.

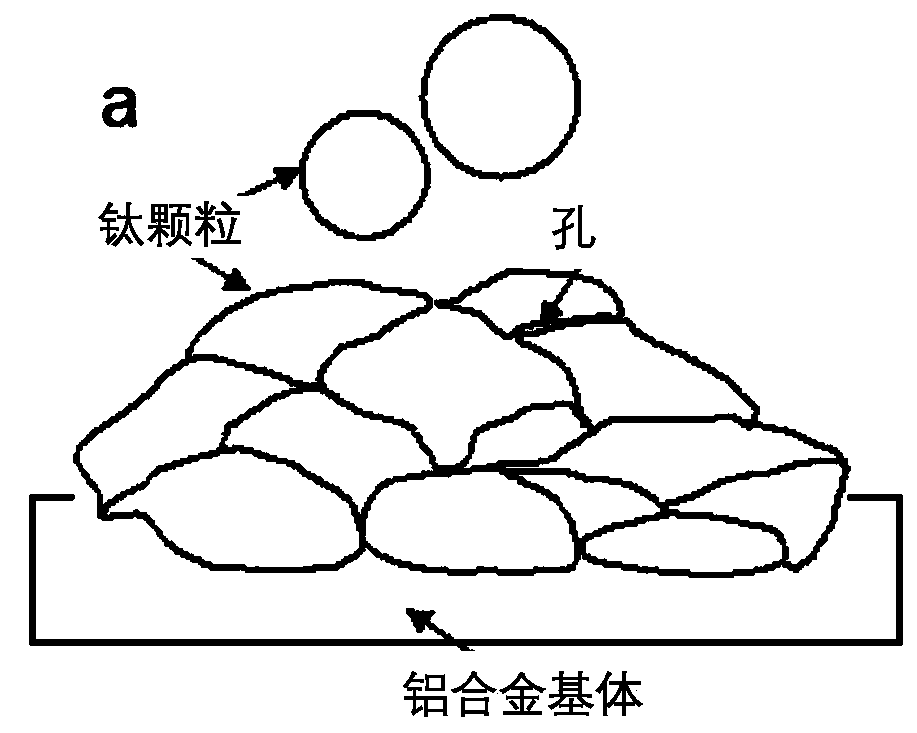

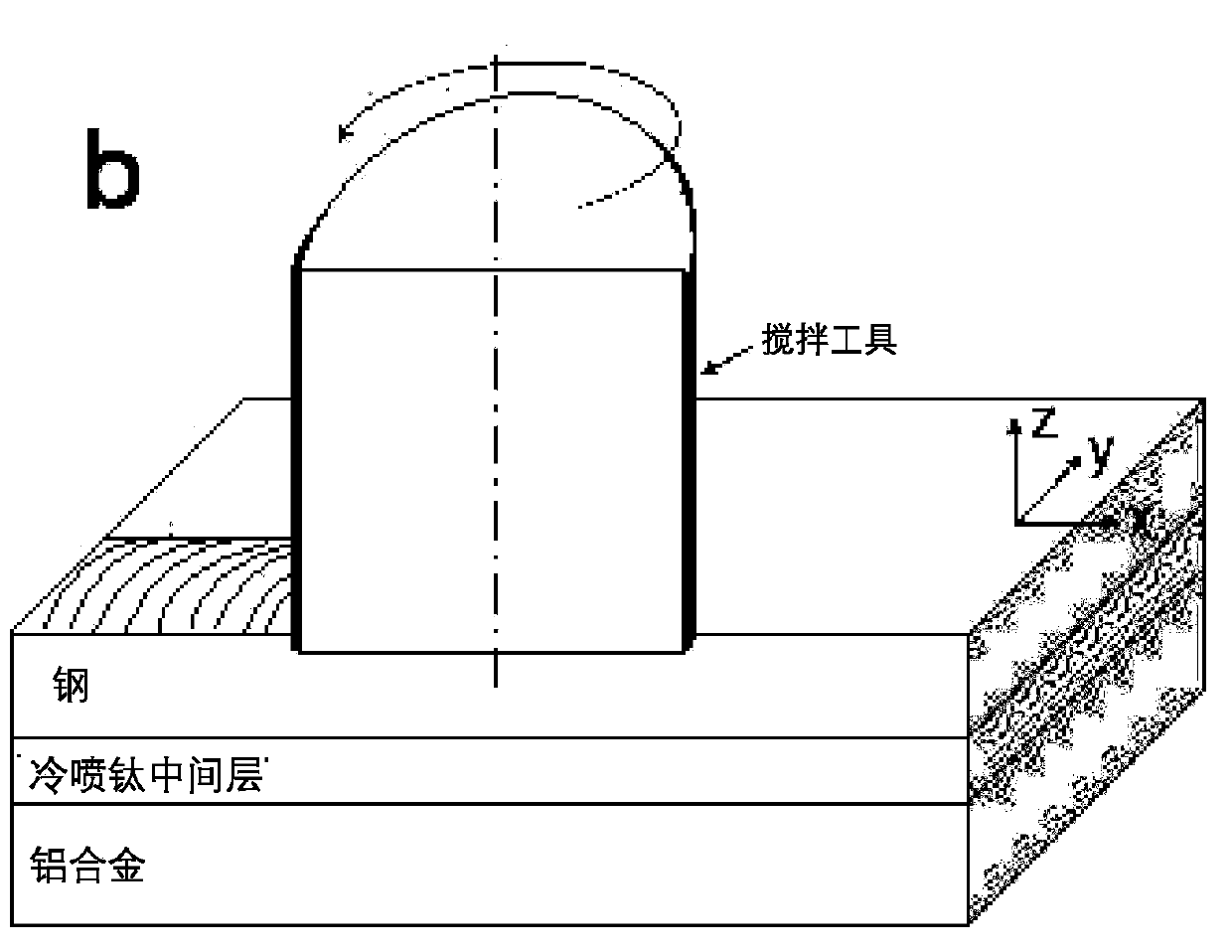

[0026] Such as Figure 1a with Figure 1b , using the cold spraying process, select Ti powder with an average particle size of 20 μm, the pressure and temperature of nitrogen are 2.8MPa and 500°C, respectively, and the spraying distance is 30mm, and a layer of Ti coating is deposited on the Al2024 substrate. The steel substrate was fixed above the middle of the Ti coating, and the friction stir welding lap process was carried out. The pressing force of the stirring head was 100 μm, and the rotation speed was 2000 rpm.

[0027] The cold-sprayed Ti-assisted friction stir welding lap joint process of aluminum-steel dissimilar metals adopted in the present invention has no obvious IMCs and thermal cracks at the joint interface, such as Figure 2a with Figure 2b , indicating that Ti coating can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com