Stone crushing and screening device for hydraulic engineering

A technology of crushing and screening, water conservancy engineering, applied in the direction of using liquid separation agent, separation method, dispersed particle separation, etc., can solve the problems of water pollution, consumption of large water resources, increase transportation cost, etc., and achieve the effect of reducing crushing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

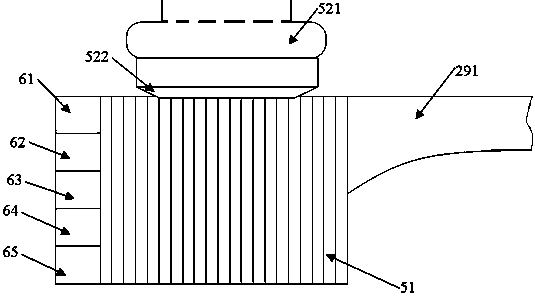

[0035] Such as Figure 1-3The shown stone crushing and screening device for water conservancy projects includes a pneumatic impact chamber, a crushing chamber, a screening device and a water purification device.

[0036] The pneumatic shock chamber includes a shell of the shock chamber, a raw material inlet, a treatment material outlet and a pneumatic shock component; the pneumatic shock component includes a lower pneumatic shock plate, a lower support plate, a lower pneumatic shock tooth, an upper pneumatic shock plate, an upper support plate and Upper pneumatic impact teeth.

[0037] The crushing chamber includes the shell of the crushing chamber, the material inlet of the crushing chamber, the rotor ingot, the main shaft, the drive shaft, the driving motor, the conveyor belt, the breaking hammer, the high-pressure water nozzle, the upper recoil plate, the upper recoil plate fixing rod, Upper recoil plate moving rod, upper recoil plate adjusting motor, lower recoil plate, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com