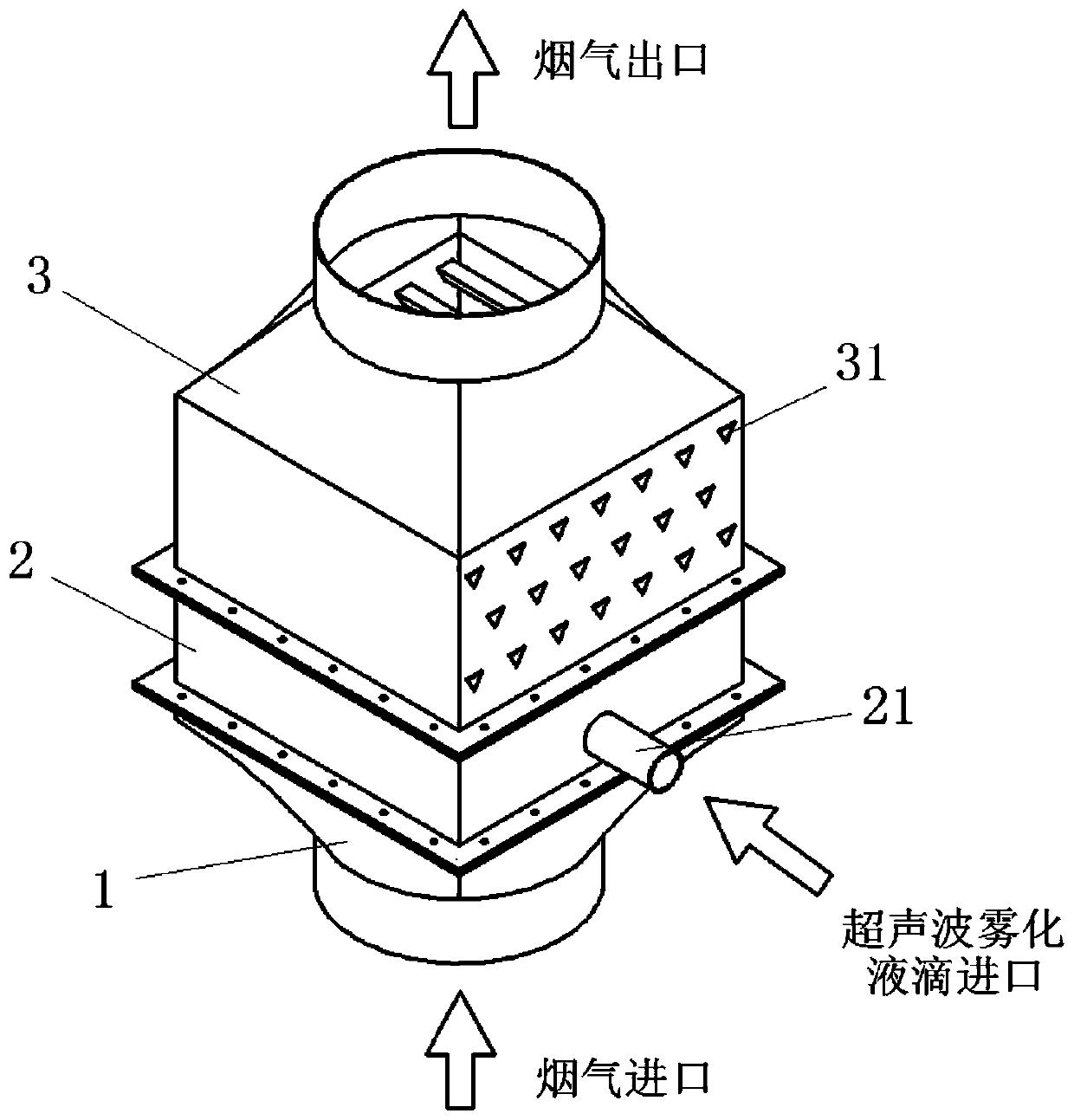

Particle agglomeration device for low temperature plasma charging ultrasonic atomization liquid drops

A low-temperature plasma, atomized droplet technology, applied in solid separation, separation methods, electrostatic effect separation, etc., can solve the problems of pipeline deposition, difficult to stabilize and effectively condense particulate matter, blockage, etc., and achieve low cost and large application. and the effect of promoting value and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0029] The invention relates to a low-temperature plasma charged particle agglomeration device for ultrasonically atomized liquid droplets, which is arranged in sequence along the flue gas flow with an inlet gradual expansion section 1 , an atomization charging section 2 and a turbulent flow agglomeration section 3 . The atomization charging section 2 includes an atomization charging tube 21 and an anti-wear tile 22, which can be used for low-temperature plasma charging of the atomized liquid droplets generated by ultrasonic atomization, and the charging voltage is 5-20kV. The particle size of the charged atomized droplets is 1-20 μm; the atomized charging tube has a tree-like branched tubular structure, and the charging area is sequentially composed of a high-voltage electrode 215, a barrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com