A dust removal waste gas treatment device

A technology of waste gas treatment device and gas outlet head, applied in separation method, sedimentation tank, separation of dispersed particles, etc., can solve the problems of insufficient absorption of absorbing liquid and waste gas, and the adsorption efficiency needs to be improved, so as to improve the adsorption effect and accelerate the precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

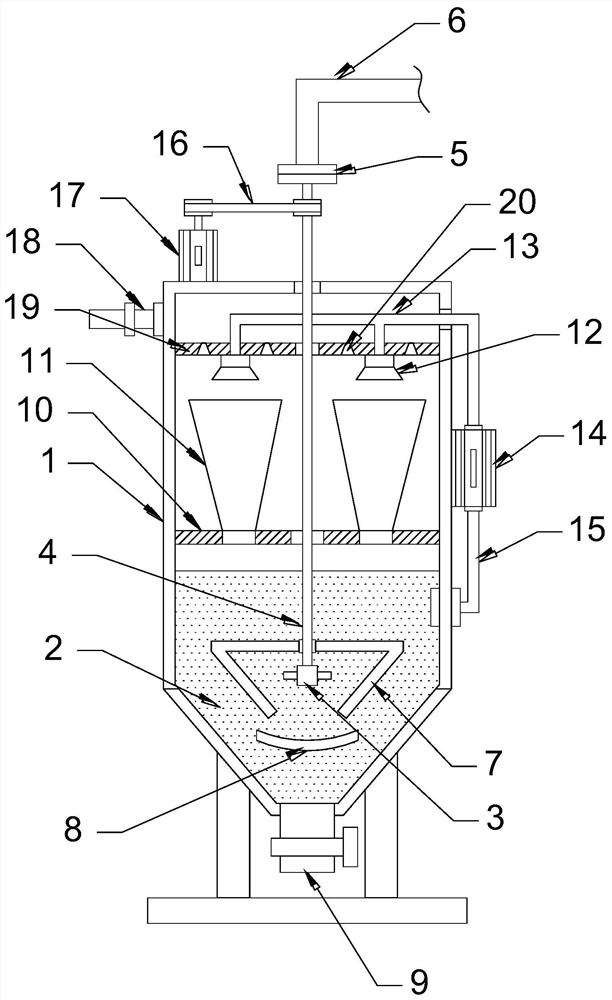

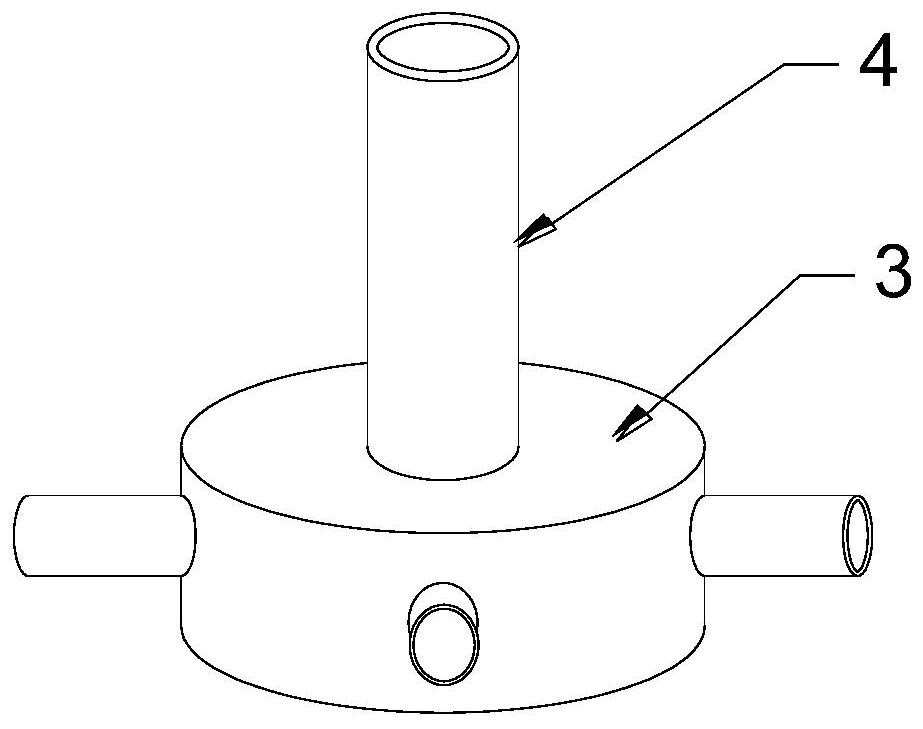

[0021] see Figure 1~4 , in an embodiment of the present invention, a dust removal waste gas treatment device includes a tank body 1, an atomizing nozzle 12 and a lift pump 14; the lower part of the tank body 1 is provided with a sedimentation chamber 2, which is a conical chamber, and 2 is filled with absorption liquid; the precipitation chamber 2 is provided with an air outlet head 3, and the air outlet head 3 is provided with a gas outlet branch pipe distributed in a circle, so that the exhaust gas is evenly dispersed in the absorption liquid, and the absorption efficiency of harmful substances is improved; the air outlet The upper end of the head 3 is communicated with a central pipe 4 , the central pipe 4 extends to the top of the tank body 1 and communicates with an air intake pipe 6 through the rotary joint 5 , and exhaust gas enters the central pipe 4 from the air intake pipe 6 .

[0022] Described settling chamber 2 is provided with stirring bar 7, and stirring bar 7 ...

Embodiment 2

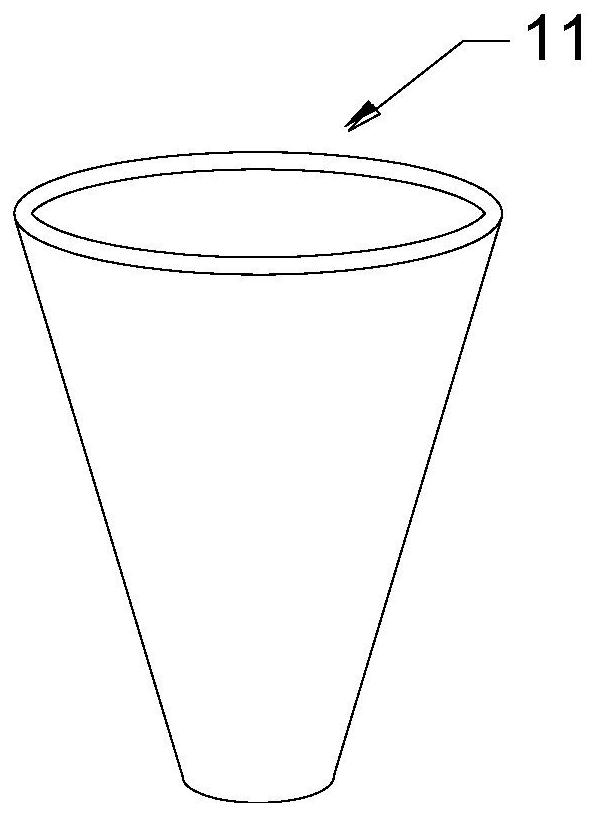

[0025] The difference between this embodiment and Embodiment 1 is that a first partition 10 is provided above the settling chamber 2, and the first partition 10 is nested with ventilators 11 distributed in a circle, and the ventilators 11 are conical cylinders. The opening diameter of the upper end of the ventilation cylinder 11 is larger than the diameter of the opening of the lower end of the ventilation cylinder 11; the ventilation cylinder 11 passes through the first partition 10 and communicates with the sedimentation chamber 2; the waste gas flows upward from the ventilation cylinder 11 after being purified by the absorption liquid; the ventilation cylinder 11 An atomizing nozzle 12 is arranged on the top, and the absorption liquid sprayed by the atomizing nozzle 12 meets the exhaust gas rising in the ventilator 11, so that the exhaust gas and the atomizing liquid are fully contacted, and the absorption effect of harmful substances in the exhaust gas is further improved; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com