Copper nanoclusters, thymine-modified hyaluronic acid, polycopper nanoclusters and preparation method and application of copper nanoclusters, thymine-modified hyaluronic acid and polycopper nanoclusters

A technology of thymine and hyaluronic acid, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve problems such as no indication of the formation of copper clusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] In some embodiments, PCuNCs synthesis method comprises:

[0074] providing a TMHA solution; in some embodiments, the TMHA solution is 0.1 mm, pH 7.0;

[0075] Add CuSO to TMHA solution 4 solution, in some embodiments, CuSO 4 The solution is 20mM, pH7.0, and added in a dropwise manner;

[0076] The mixture is thus allowed to react; in some embodiments, react at 37° C. for 20 minutes in the dark to obtain the PCuNCs solution; store the PCuNCs solution at 4° C. in the dark for use.

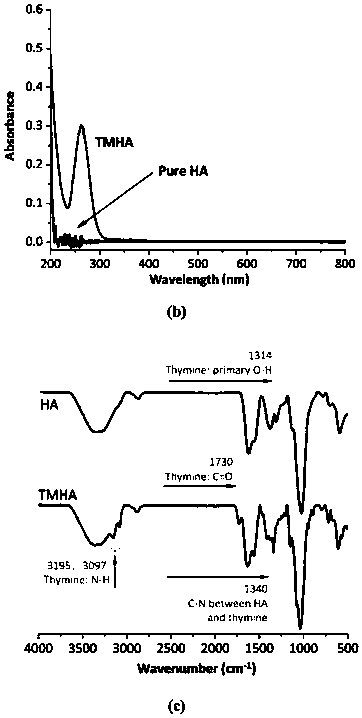

[0077] Under the irradiation of UV light (365 nm), the bright orange-red emission can be clearly seen, indicating that the formation of luminescent CuNCs is successful.

[0078] In some embodiments, the molar ratio between Cu and TMHA is in the range of 10:1 to 500:1, further in the range of 15:1 to 300:1, further in the range of 20:1 to 200:1 , further in the range of 25:1 to 100:1, and further in the range of 30:1 to 80:1.

[0079] PCuNCs contain well-dispersed spherical nanoclusters with...

Embodiment 1

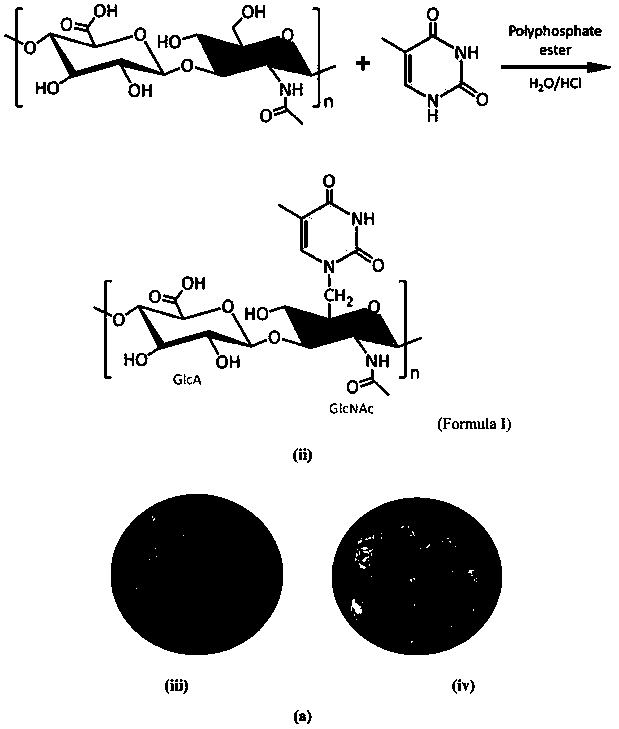

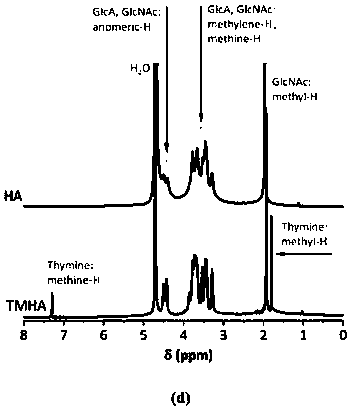

[0093] Embodiment 1, the synthesis of thymine-modified hyaluronic acid (TMHA)

[0094] First, polyphosphate is prepared as a catalyst. Diethyl ether (14.5 mL) and CHCl 3 (5.6mL) was added into phosphorus pentoxide (10g), stirred, and heated under reflux at 50°C for 12h to obtain a clear solution. After cooling to room temperature, the solvent was distilled off under vacuum. The resulting colorless sticky residue was polyphosphate and was used as catalyst without further purification.

[0095] TMHA was synthesized as follows. dissolved in 25mL of HCl added with 0.25mL of concentrated hydrochloric acid solution (25%) 2 In O, a clear solution of thymidine (23.6 mg) was obtained. Polyphosphate (1.5g) was added to HA solution (50mL, 2.2wt%; MW120KD), then thymine was dripped, the mixture was heated to 50°C in an oil bath for 16h, and cooled to 0°C to precipitate unreacted thymine . The supernatant was then dialyzed through a dialysis bag (MWCO 8000) for 72 hours to remove an...

Embodiment 2

[0098] Example 2: Synthesis of polycopper clusters (PCuNCs) with TMHA

[0099] 10 mL of TMHA (10.5% DS) solution (0.1 mM, pH 7.0) was gradually heated to 37° C. to dissolve TMHA. 2 mL of copper sulfate (20 mM, pH 7.0) solution was added dropwise, and reacted at 37° C. for another 20 minutes in the dark. Under the irradiation of ultraviolet light (365 nm), the bright orange-red emission can be clearly seen, indicating that the formation of luminescent PCuNCs is successful. Finally, the resulting solution was stored in the dark at 4°C until use.

[0100] Cu was studied separately 2+ / TMHA molar ratio, pH value, reaction temperature, reaction time and other optimal synthesis conditions. In order to examine the Cu in the reaction system 2+ content, add 2mL CuSO of different concentrations to 10mL TMHA solution 4 , so that Cu in the reaction system 2+ The molar ratio to TMHA is 5:1, 10:1, 15:1, 20:1, 30:1, 40:1, 60:1, 80:1, 100:1. After reacting with mild stirring at 37°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com