Bipolar plate for fuel cell stacks, composite material and preparation process

A technology of fuel cell stacks and composite materials, which is applied in the field of fuel cells and can solve problems such as difficult diffusion bonding and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

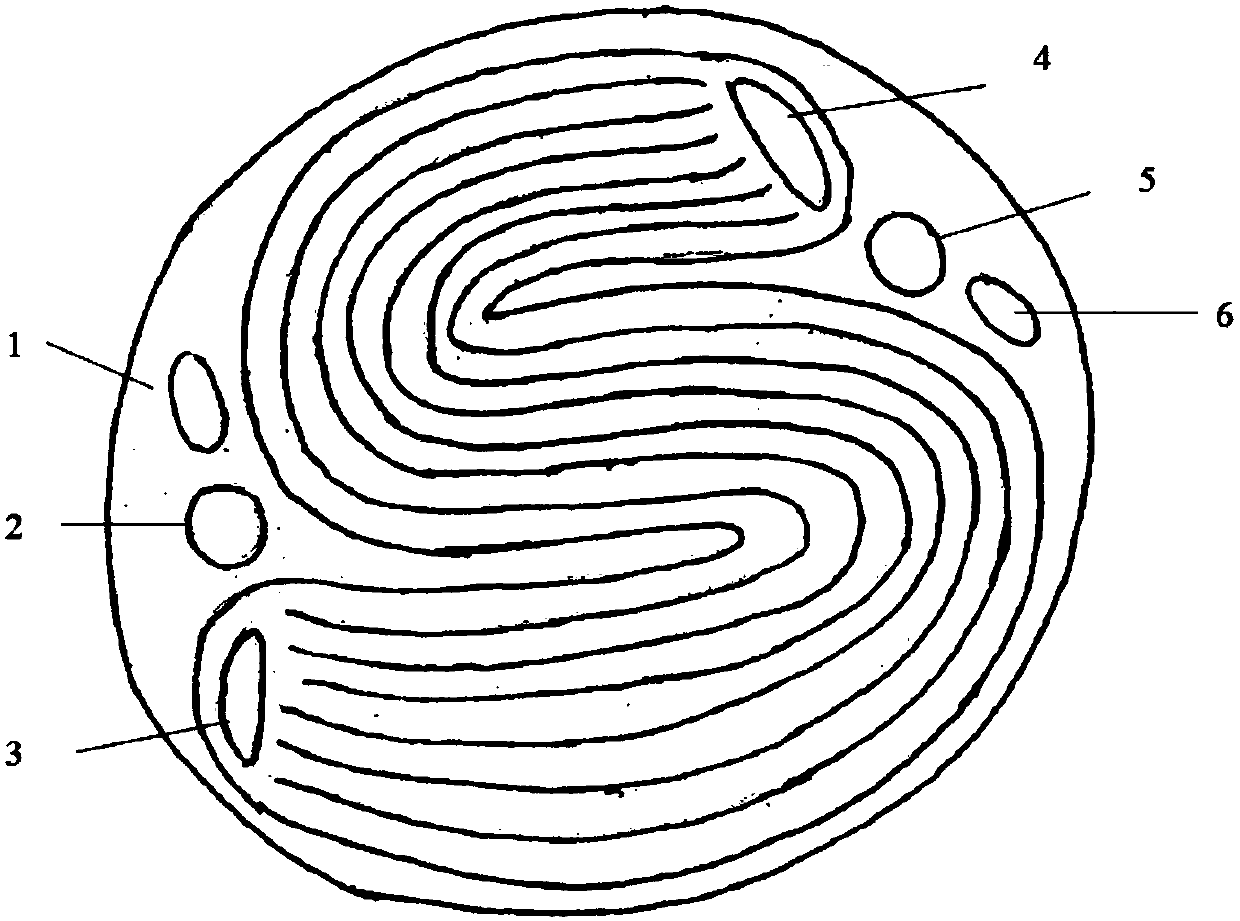

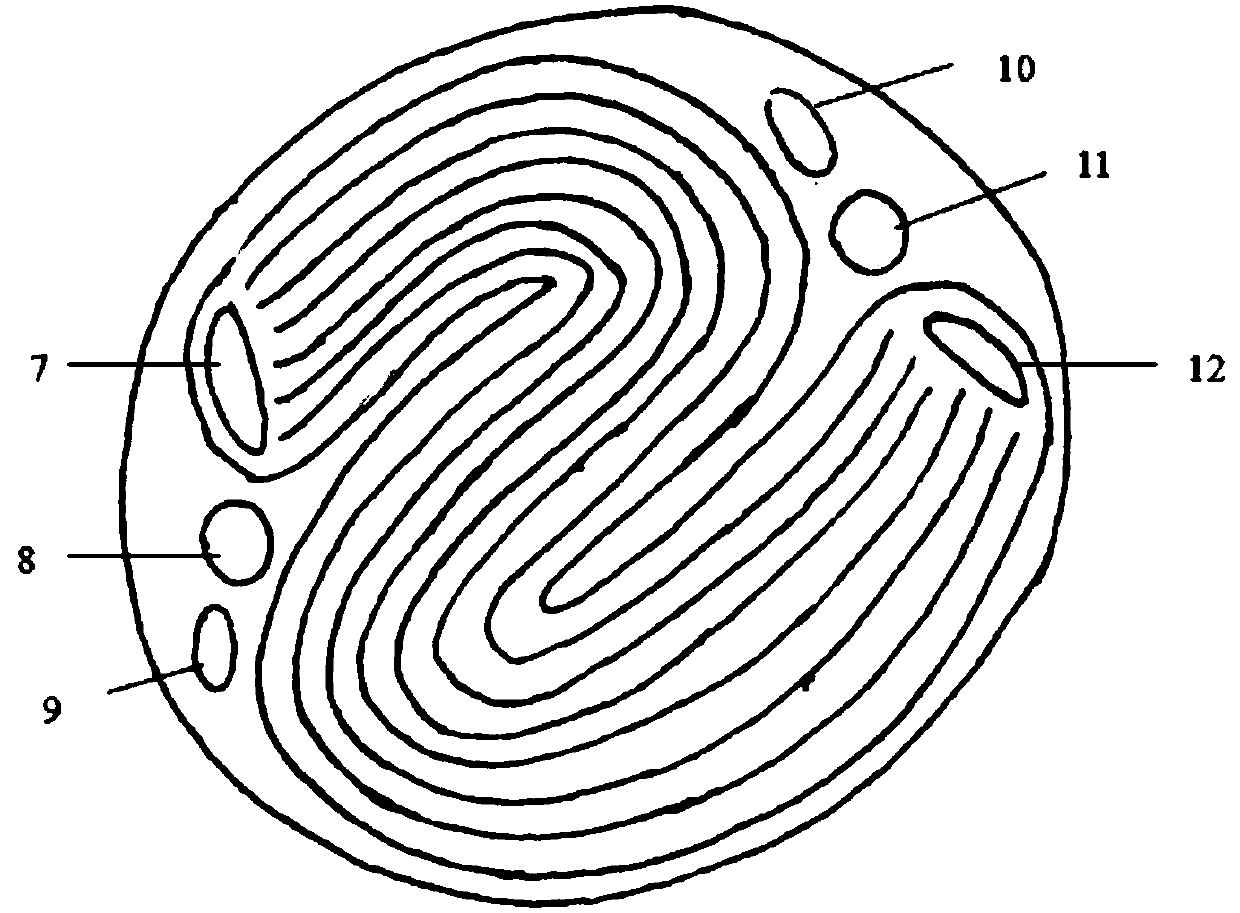

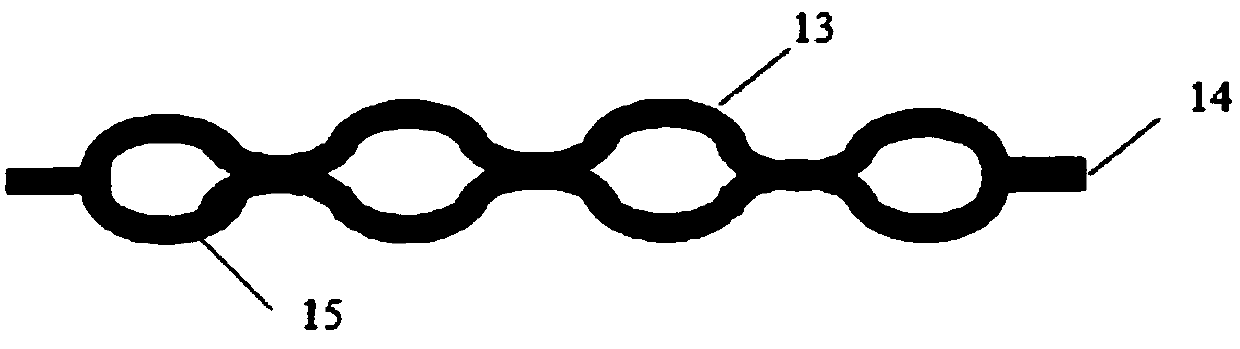

[0073] see figure 1 , the present invention discloses a bipolar plate for a fuel cell stack, the bipolar plate includes: a cathode flow field plate, an anode flow field plate, and the cathode flow field plate and the anode flow field plate are joined together, using The bonding process joins the edges of the cathode flow field plate and the anode flow field plate. A coolant channel is left between the cathode flow field plate and the anode flow field plate.

[0074] The cathode gas inlet 3 flows through the S-shaped gas channel to the cathode gas outlet 4, and the cross-sectional area of the gas channel changes from wide to narrow.

[0075] The cathode cooling liquid inlet 2 and the cathode cooling liquid outlet 5 communicate with each other from inside the bipolar plate, and the cooling liquid flows from the inside of the bipolar plate.

[0076] The anode gas inlet 1 and the anode gas outlet 6 are connected by an anode flow field, and the flow direction of the anode gas i...

Embodiment 2

[0093] The bipolar plate is made of composite material, and the composite material contains conductive aggregate with a weight ratio of 75% to 84%, 16% to 25% of adhesive and curing agent; the conductive aggregate is processed by potassium permanganate solution Treatment changes surface chemistry;

[0094] The conductive aggregate is formed by mixing flake graphite and powder graphite or carbon black, and the weight ratio of flake graphite to powder graphite is 16-5.4;

[0095] Described binder adopts thermoplastic polyimide resin or phenolic resin solution, wherein the solid content of thermoplastic polyimide resin or phenolic resin is 63%~70%; The weight ratio of crosslinking agent hexamethylenetetramine is 2-4%, and the weight ratio of filler silicon dioxide is 2-5%.

[0096] see figure 1 , the present invention discloses a bipolar plate for a fuel cell stack, the bipolar plate includes: a cathode flow field plate, an anode flow field plate, the cathode flow field plate a...

Embodiment 3

[0108] The invention discloses a composite material for preparing fuel cell stack bipolar plates, specifically as follows:

[0109] Conductive aggregate: In the composite material of the present invention, the conductive aggregate used is a mixed powder of flake graphite and graphite powder or carbon black. The particle size of flake graphite is generally 10000 mesh, and the particle size of graphite powder or carbon black is It is 800 mesh. The ratio of the two graphites in the bipolar plate composite material is: flake graphite / graphite powder is 16-5.4, the amount of conductive aggregate accounts for 85%-75% of the weight of the composite material, and the preferred value is 80%-84%. , The conductive aggregate is first treated with potassium permanganate solution, washed and then dried for use.

[0110] Binder resin: The binder resin not only plays the role of bonding other solid particles in the composite material together, but also affects the strength of the bipolar pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com