Two-dimensional-arrangement double-sided staggered embedded type three-dimensional detector and preparation method and array thereof

A two-dimensional arrangement and detector technology, applied in semiconductor devices, final product manufacturing, radiation control devices, etc., can solve the problems of easy breakdown position resolution, the number of electronic readout channels, and the complexity of electronics, etc. Achieve the effects of reduced risk of breakdown, uniform electric field distribution, and improved position resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

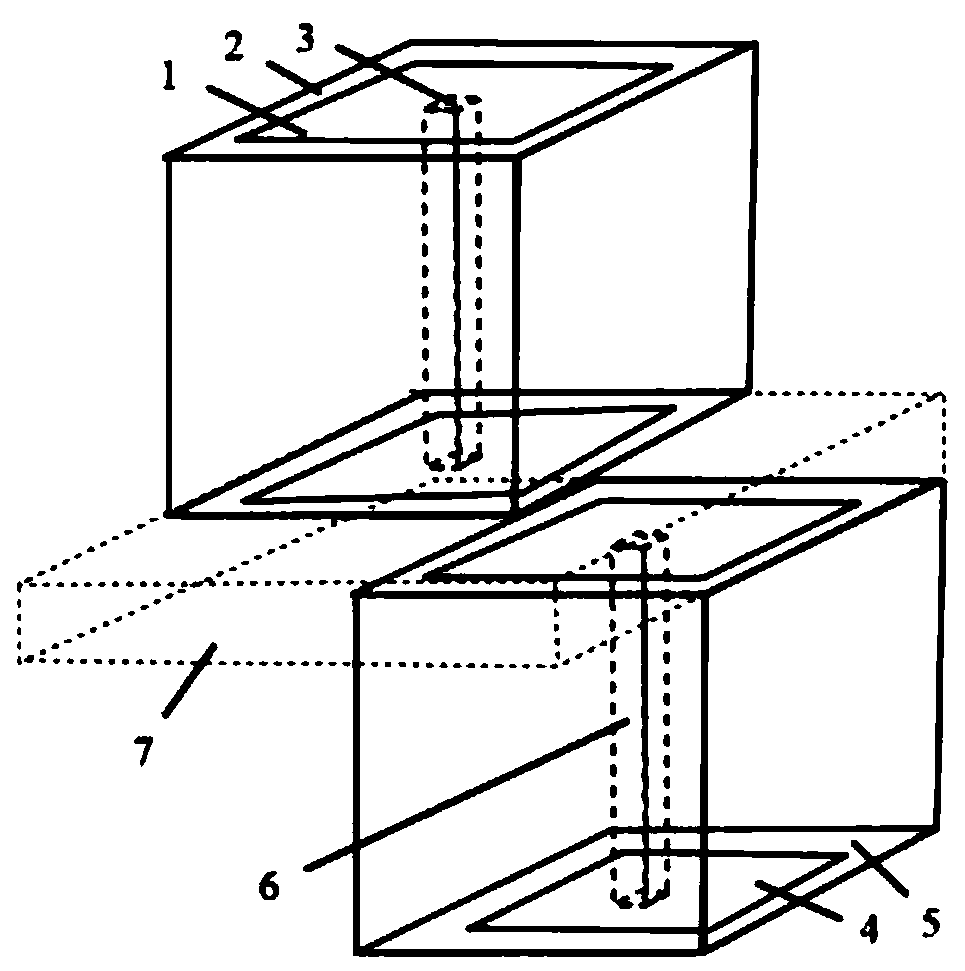

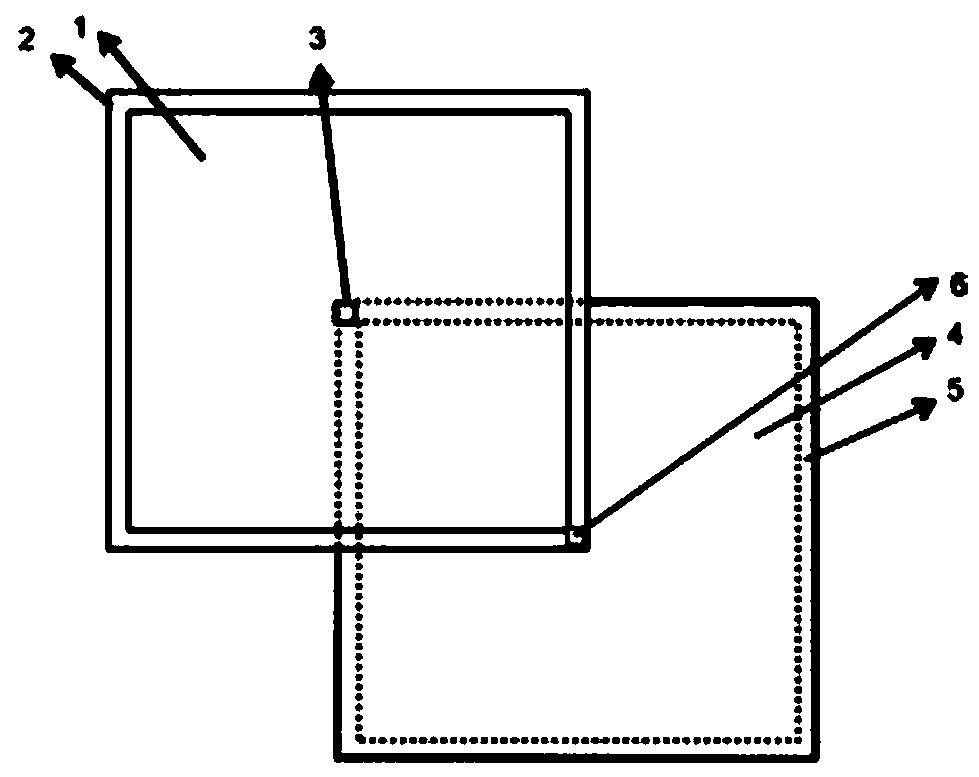

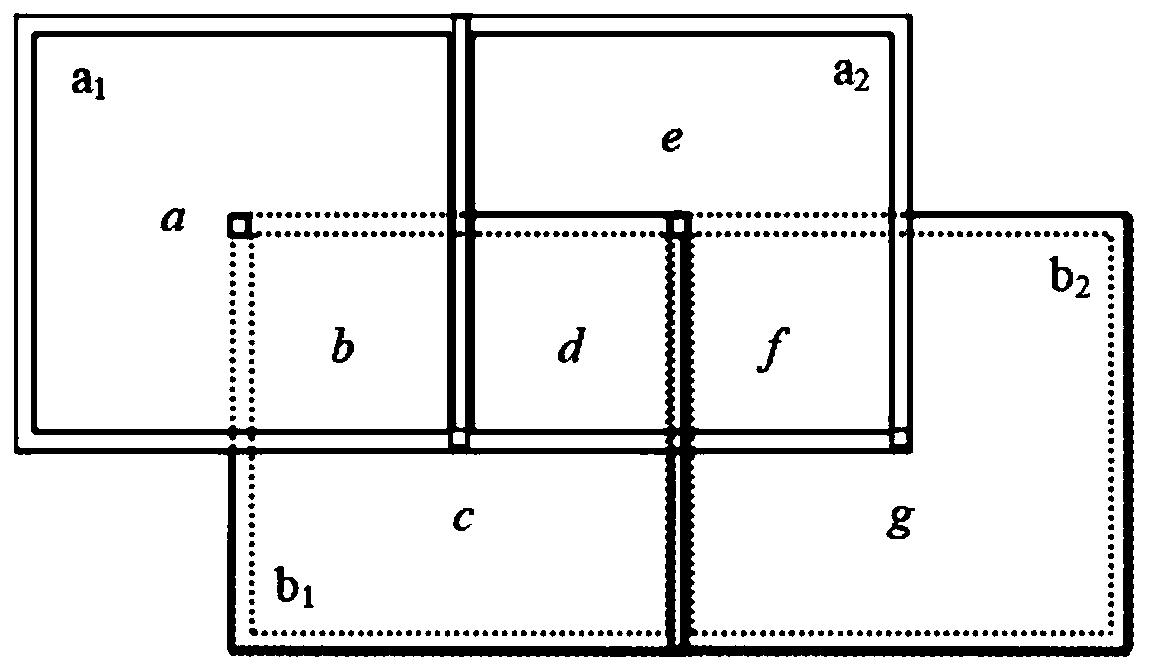

[0033] Two-dimensional arrangement of double-sided staggered three-dimensional detectors, such as Figure 1~3 As shown, the third silicon base 7 is included, the upper surface of the third silicon base 7 is etched with the upper trench electrode 2, the lower surface of the third silicon base 7 is etched with the lower trench electrode 5, the upper trench electrode 2 and the lower trench The groove electrode 5 is a hollow cuboid structure, the upper groove electrode 2 is embedded with the upper central electrode 3, the lower groove electrode 5 is embedded with the lower central electrode 6, and the gap between the upper central electrode 3 and the upper groove electrode 2 is filled with The lower semiconductor base 4 is filled between the upper semiconductor base 1 , the lower trench electrode 5 and the lower central electrode 6 . The outer length of the upper trench electrode 2 is 2R X , the outer width is 2R Y , the vertical distance between the centers of the upper central...

Embodiment 2

[0035] The difference from embodiment 1 is that the upper trench electrode 2 and the lower trench electrode 5 in this embodiment have a doping concentration of 25×10 18 cm -3 The p-type heavily doped silicon substrate; the upper central electrode 3 and the lower central electrode 6 have a doping concentration of 25×10 18 cm -3 n-type heavily doped silicon substrate.

Embodiment 3

[0037] The difference from Examples 1-2 is that the upper trench electrode 2 and the lower trench electrode 5 in this example have a doping concentration of 5×10 19 cm -3 The p-type heavily doped silicon substrate; the upper central electrode 3 and the lower central electrode 6 have a doping concentration of 5×10 19 cm -3 n-type heavily doped silicon substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com