Electrolyte for ultra-low temperature and high voltage patch aluminum capacitor and preparation method thereof

A high-voltage, chip-type technology, applied in the field of capacitors, can solve the problems of short-circuit, leakage current recovery, and impedance increase of chip capacitors, and achieve the effect of reducing ESR.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

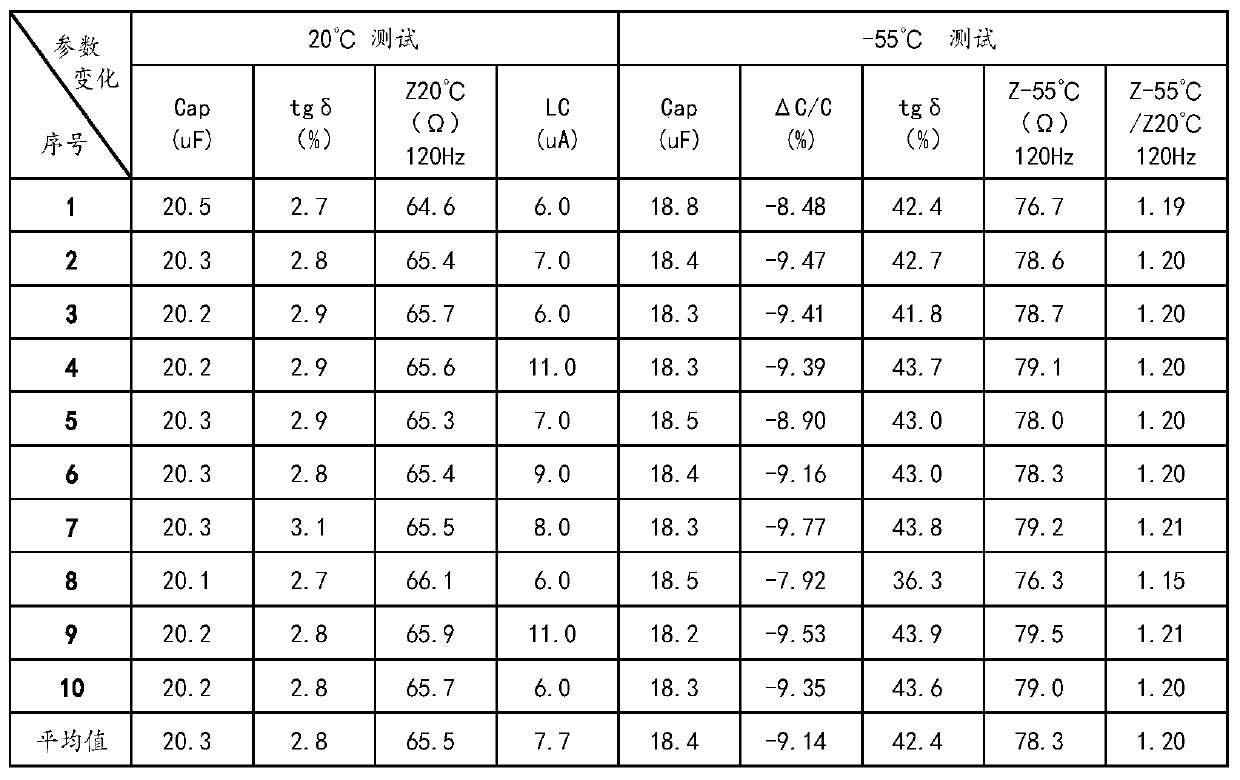

Image

Examples

Embodiment 1

[0020] ①Heat the main solvent: 35.2% of γ-butyrolactone and 22.4% of ethylene glycol and auxiliary solvents of 8.2% of diethylene glycol monomethyl ether and 7.7% of diethylene glycol butyl ether in the reaction kettle to 85 ℃.

[0021] ②Slowly add flash fire voltage enhancer: 2.5% polypropylene alcohol and 1.5% nano-silicon dioxide and raise the temperature to 135°C for 70 minutes.

[0022] ③Reduce the temperature to 70°C and add solutes: 8.3% 2-methylammonium azelate and 3.4% 7,8-dimethyltetradecaneammonium tetracarboxylate and raise the temperature to 125°C for 40 minutes.

[0023] ④Reduce the temperature to 80°C and add 2.5% p-nitrobenzyl alcohol as a dehydrogenating agent, then raise the temperature to 110°C and keep the temperature for 20 minutes.

[0024] ⑤ Cool down to 55°C and add 8.3% ethylene glycol, boric acid, glycerol, polyvinyl alcohol, sebacic acid, phosphoric acid and its derivatives to react at 130-165°C for 3-6 hours as a modified synthetic additive The pr...

Embodiment 2

[0027] ①Heat the main solvent: 30.9% of γ-butyrolactone and 12.1% of ethylene glycol and the auxiliary solvent of 18.2% of diethylene glycol diethyl ether and 13.8% of diethylene glycol butyl ether in the reaction kettle to 85°C .

[0028] ②Slowly add flash fire voltage enhancer: 2.0% polypropylene alcohol and 1.5% high polyethylene glycol and raise the temperature to 135°C for 70 minutes.

[0029] ③Reduce the temperature to 70°C and add solutes: 8.7% ammonium 5,6-sebacate and 3.3% ammonium 1,6-dodecanedioate and raise the temperature to 125°C for 40 minutes.

[0030] ④Reduce the temperature to 80°C and add 2.1% m-nitroacetophenone as a dehydrogenating agent, then raise the temperature to 110°C and keep the temperature for 20 minutes.

[0031] ⑤ Cool down to 55°C and add 7.4% ethylene glycol, boric acid, glycerol, polyvinyl alcohol, sebacic acid, phosphoric acid and its derivatives to react at 130-165°C for 3-6 hours as a modified synthetic additive The product is completed ...

Embodiment 3

[0033] ① Heat the main solvent: 10.9% of diethylene glycol and 36.1% of γ-butyrolactone and the auxiliary solvent of 16.2% of diethylene glycol monomethyl ether and 9.8% of dimethyl sulfoxide to 85°C in the reaction kettle .

[0034] ②Slowly add flash fire voltage enhancer: 2.2% polyvinyl alcohol and 4.8% nano-silicon dioxide and raise the temperature to 135°C for 70 minutes.

[0035] ③Reduce the temperature to 70°C and add solutes: 9.3% ammonium 1,7-sebacate and 3.7% ammonium tridecanetricarboxylate and heat up to 125°C for 40 minutes.

[0036] ④Reduce the temperature to 80°C and add 1.8% p-nitrobenzoic acid as a hydrogen remover, and raise the temperature to 110°C for 20 minutes.

[0037] ⑤ Cool down to 55°C and add 5.2% ethylene glycol, boric acid, glycerol, polyvinyl alcohol, sebacic acid, phosphoric acid and its derivatives to react at 130-165°C for 3-6 hours as a modified synthetic additive The product is completed after 30 minutes of incubation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com