A Fault Monitoring Method Based on Hierarchical Density Peak Clustering and Most Similar Modes

A technology for fault monitoring and density peaks, applied in electrical testing/monitoring and other directions, which can solve problems such as multi-modal fault monitoring methods relying on prior modal information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

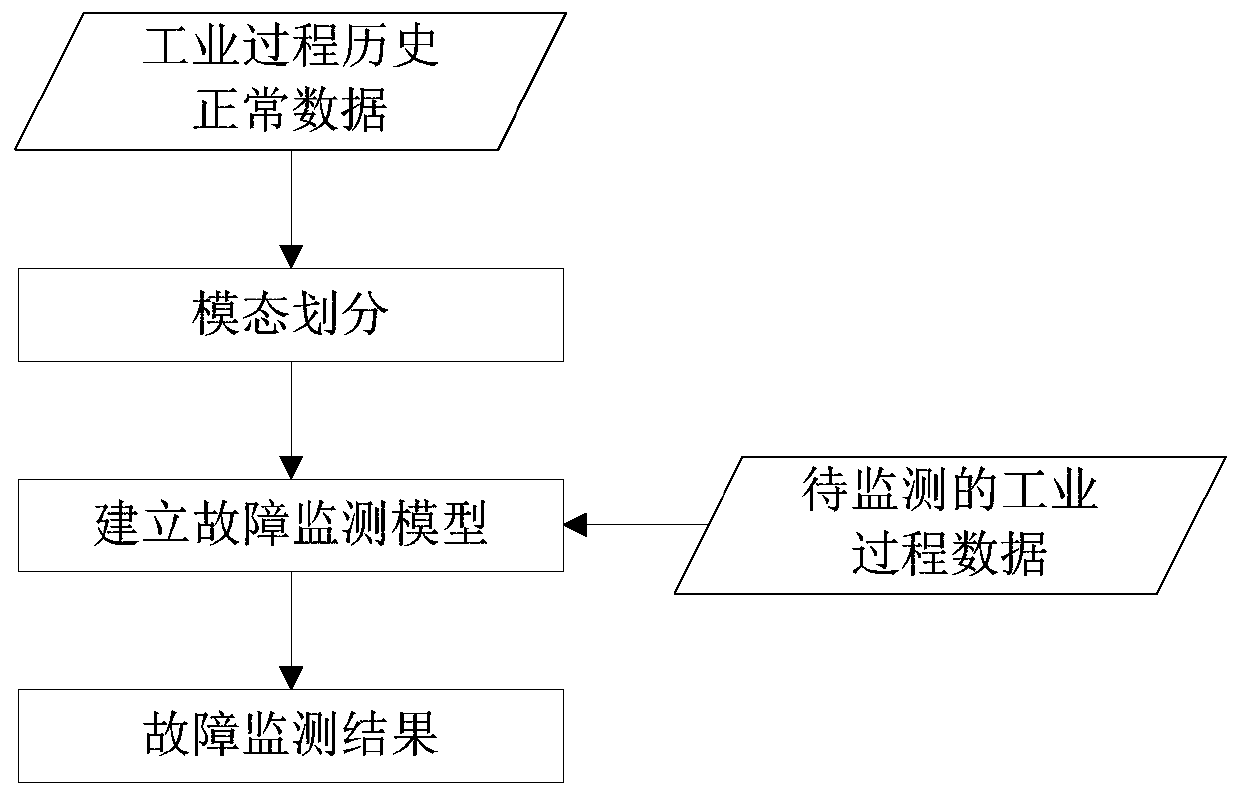

[0067] Such as figure 1 Shown is the flow chart of the method of the present invention.

[0068] Based on the fault monitoring method of hierarchical density peak clustering and the most similar mode, the industrial process data is collected, and after obtaining the hierarchical mode information, the independent element analysis and the most similar mode are used for fault monitoring.

[0069] Concrete steps of the present invention are as follows:

[0070] Step 1: Collect historical normal data of penicillin fermentation process, including ventilation rate, agitator power, substrate feeding speed, heat generated by reaction, medium volume, carbon dioxide concentration, pH value, temperature, dissolved oxygen saturation, and conduct Standardized processing, the mean value of each variable of the processed data is 0, and the variance is 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com