a baga 4 the se 7 Polycrystalline synthesis device and synthesis method

A synthesis device and synthesis method technology, applied in polycrystalline material growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of component deviation, yield drop, low reactivity of liquid metal Ga, etc., to achieve production rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

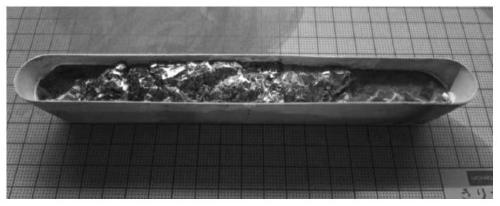

Examples

Embodiment 1

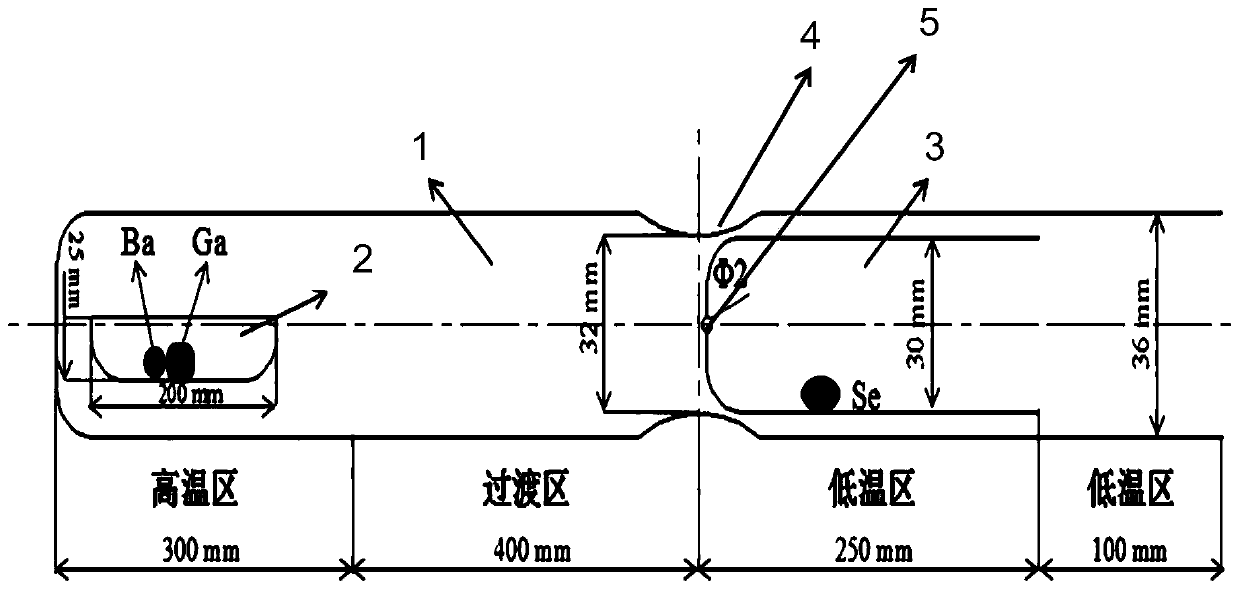

[0033] Such as figure 1 As shown, a BaGa 4 Se 7 A polycrystalline synthesis device, the polycrystalline synthesis device comprises a gas phase transport quartz tube 1, a boron nitride boat 2 and a small quartz tube 3;

[0034] The gas-phase transmission quartz tube 1 is a quartz tube with one end closed, and an annular groove 4 is formed in the tube wall in the middle of the quartz tube, which divides the gas-phase transmission quartz tube into two parts. The end is the transition zone and the high temperature zone in turn, and the ring groove to the open end is the low temperature zone;

[0035] The boron nitride boat is used to contain high-purity barium element and gallium element, and placed in the high temperature zone of the gas phase transmission quartz tube 1;

[0036] The small quartz tube is used to contain simple selenium and is placed in the low temperature area of the gas phase transmission quartz tube (1). One end of the small quartz tube is closed, and a sm...

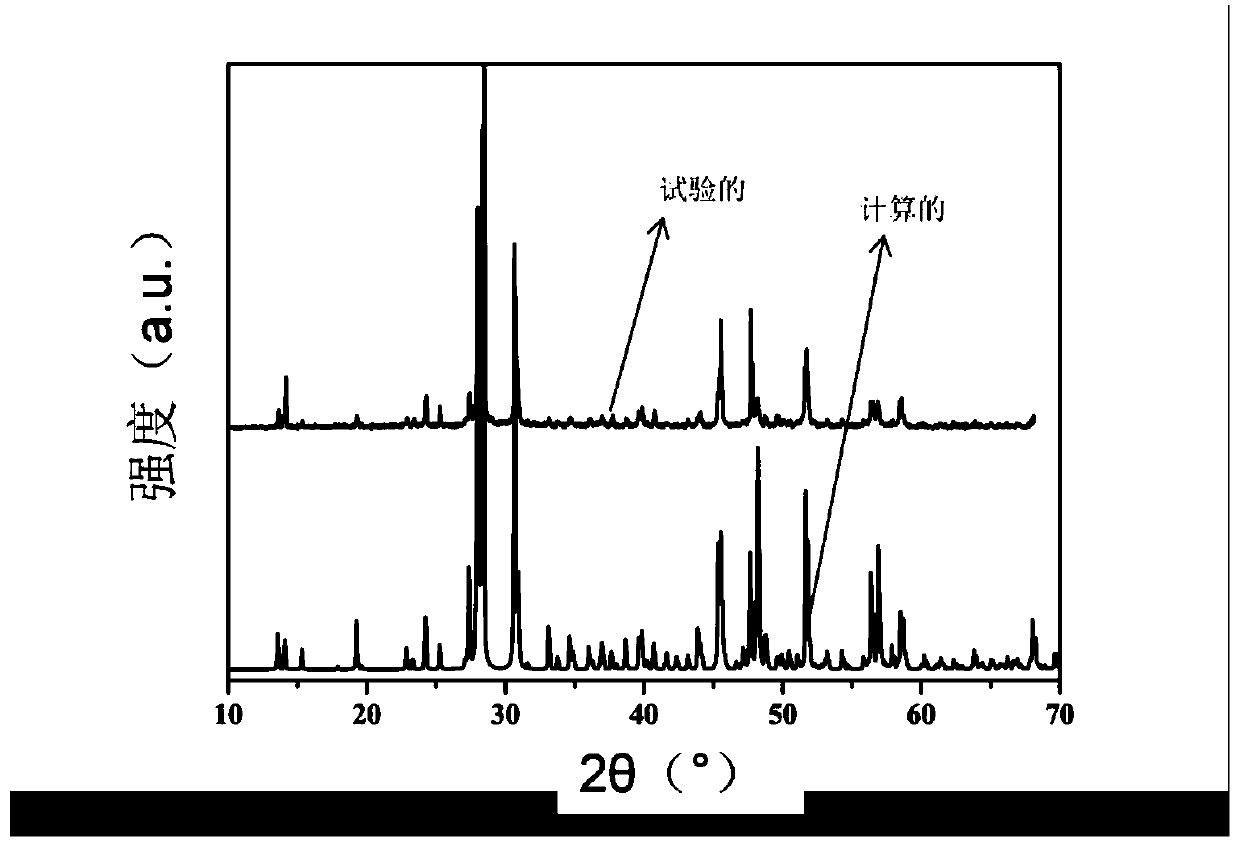

Embodiment 2

[0040] In the present embodiment, the synthesis device described in Example 1 is adopted, and the raw materials barium (Ba), gallium (Ga), and selenium (Se) used are all 6N grades. During batching, the molar ratio of each raw material is barium: gallium: Selenium = 1:4:7, and according to the above ratio, appropriate selenium-enriched (1%-3% excess) ingredients: 35.082 grams of barium, 71.252 grams of gallium, and 142.617 grams of selenium. The synthesis process steps are as follows:

[0041] 1. Reaction vessel cleaning and drying

[0042] Rinse the gas-phase transmission quartz tube, boron nitride boat, and the inner wall of the small quartz tube with tap water, soak in aqua regia for 24 hours, then rinse with tap water until neutral, place in an ultrasonic cleaning tank for oscillating cleaning for 30 minutes, and use Rinse with deionized water repeatedly, then clean with high-purity alcohol, and dry in an oven at 100°C for later use.

[0043] 2. Loading

[0044] First pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com