SBR modified emulsified asphalt and preparation method thereof

A technology for emulsified asphalt and modification, applied in building components, building insulation materials, buildings, etc., can solve the problems of strict production equipment and process requirements, poor high-temperature performance, general low-temperature performance, etc., and achieve good low-temperature crack resistance. performance, improved high temperature performance, increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

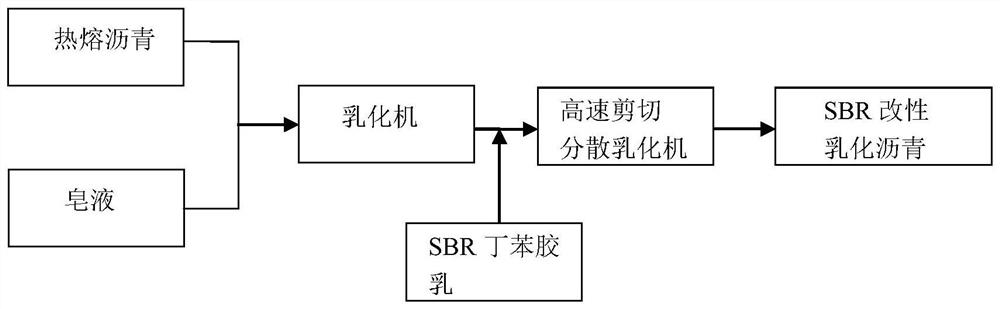

[0035] The preparation method of SBR modified emulsified asphalt of the present invention, as figure 1 As shown, follow the steps below:

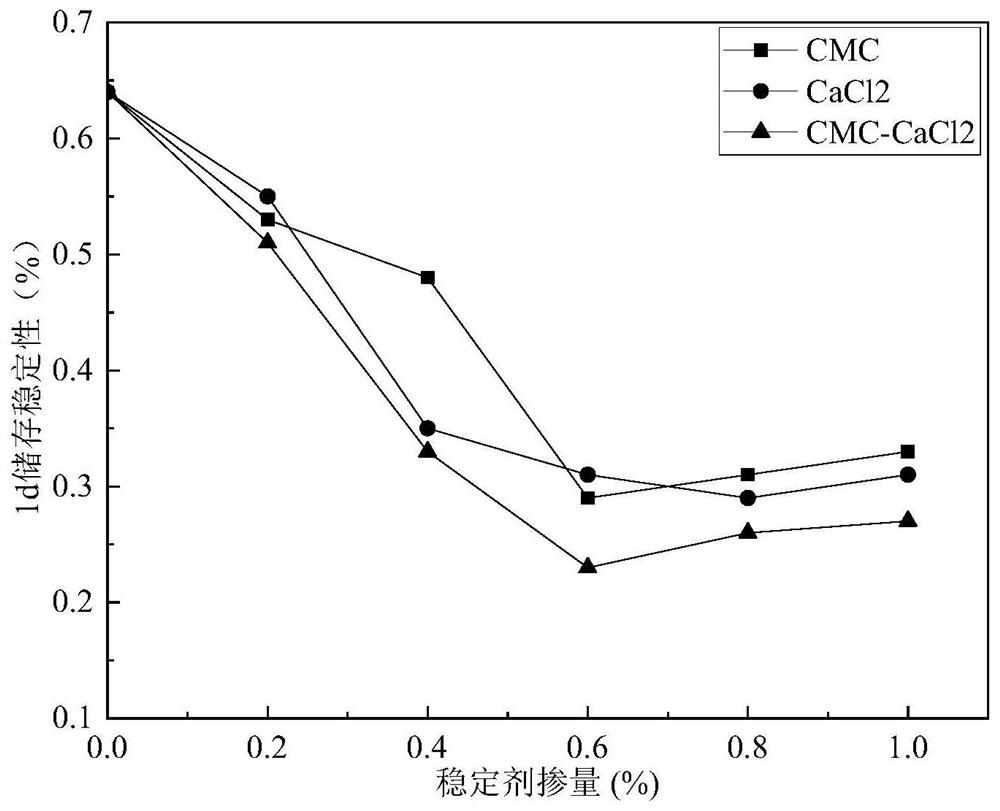

[0036] S1, weigh 66-69 parts of base asphalt according to the following parts by mass, 2-3 parts of CMK-50 cationic emulsifier, 3-4 parts of SBR styrene-butadiene latex, 0.2-0.4 parts of carboxymethyl cellulose (CMC), Anhydrous Calcium Chloride (CaCl 2 ) 0.2-0.4 parts, water 29-31 parts.

[0037] S2, heat the weighed base asphalt to a hot-melt state of 130-140°C, pour it into the asphalt tank, set the colloid mill speed to 9000-10000r / min, open the internal circulation system of the asphalt tank, and disperse the hot-melt asphalt into Homogeneous body; last for 25-35 minutes, the function is to disperse the hot-melt asphalt into a homogeneous body, which is beneficial to the emulsification effect.

[0038] S3, preparation of soap solution: heat water to 85-90°C, add carboxymethyl cellulose, stir with glass rod until carboxymethyl cellulo...

Embodiment 1

[0043] Example 1, SBR modified emulsified asphalt is composed of the following parts by mass: 66 parts of 70# heavy traffic asphalt, 3 parts of CMK-50 cationic emulsifier, 4 parts of SBR styrene-butadiene latex, 0.2 parts of carboxymethyl cellulose, no 0.4 parts of calcium chloride water, 31 parts of water.

Embodiment 2

[0044] Example 2, SBR modified emulsified asphalt is composed of the following parts by mass: 69 parts of 70# heavy traffic asphalt, 2 parts of CMK-50 cationic emulsifier, 3 parts of SBR styrene-butadiene latex, 0.4 parts of carboxymethyl cellulose, no 0.2 parts of calcium chloride water, 29 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com