Antifreeze polysaccharide composite starch hydrogel, preparation method and application

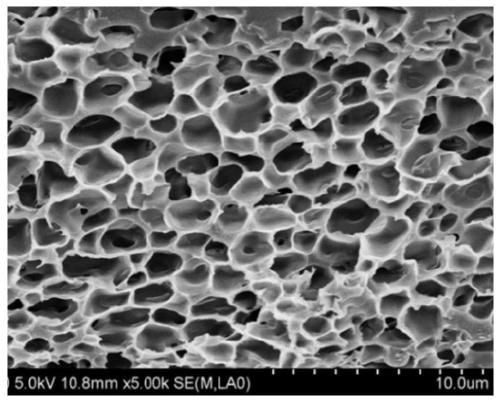

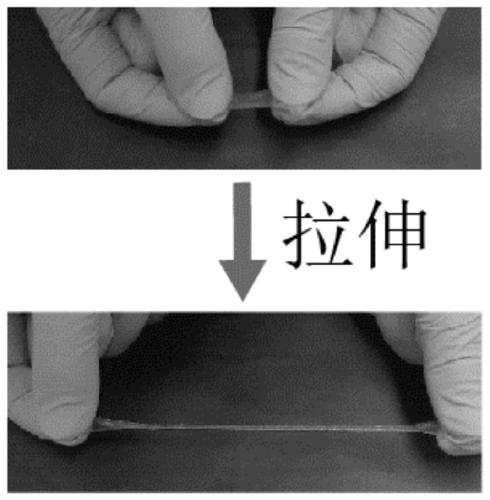

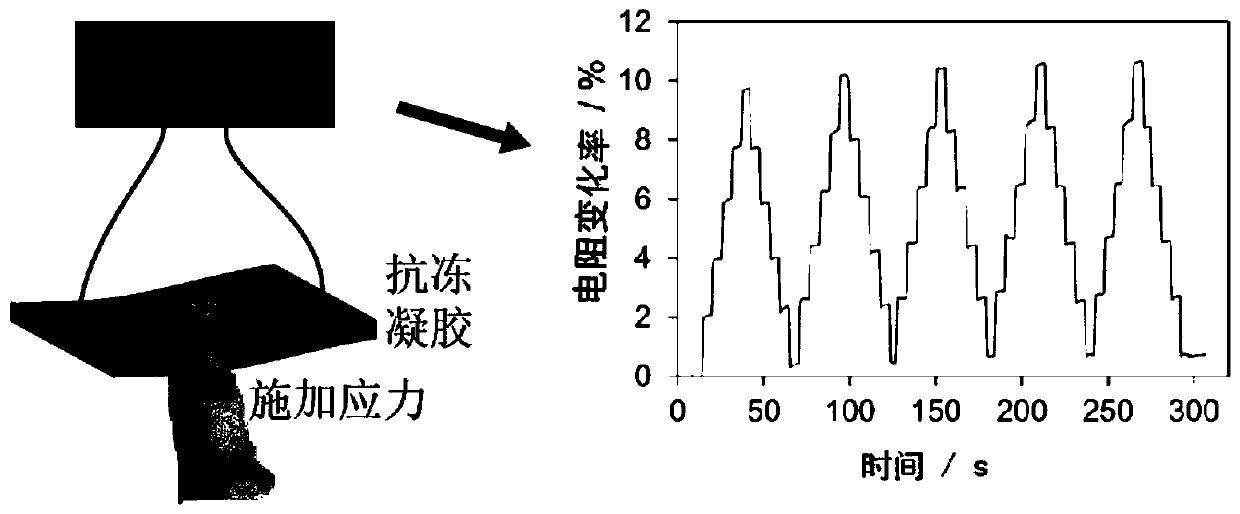

A polysaccharide composite and hydrogel technology, which is applied in the field of antifreeze hydrogel materials, can solve the problems that the mechanical integrity of the hydrogel cannot be guaranteed, and achieve easy repeatability and mass production, simple methods, and high tensile elongation The effect of rate and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Filter the Flammulina velutipes mycelium strainer, wash two to three times with water, collect the precipitate, freeze-dry, and pulverize into powder with a small laboratory grinder; add the Flammulina velutipes mycelium powder to distilled water (quality of mycelial solid powder: distilled water After mass=1:20), extract in a water bath at 100°C for 3 hours, repeat three times, collect the supernatant after centrifugation, concentrate, and precipitate with ethanol. The volume ratio is supernatant: ethanol=1:3. Collect the solid and dry.

[0029] Step 2: Use commercially available sweet potato starch, add it to deionized water, stir at room temperature to form a starch milk with a mass fraction of 10.0%, adjust the pH to 10.0 with 0.1 mol / L NaOH solution, and add NaCl (2.0% of the starch mass) to inhibit Starch granules swell; add 1, 6-hexanediol diglycidyl ether (3.0% of starch quality) and tetrabutylammonium bromide (0.6% of starch quality) to the prepared starch ...

Embodiment 2

[0035] Step 1: Filter the Flammulina velutipes mycelium filter, wash two to three times with water, collect the precipitate, freeze-dry, and pulverize into powder with a small laboratory grinder; add the Flammulina velutipes mycelium powder to distilled water (quality of mycelial solid powder: distilled water Mass=1:30), extract 4h in a water bath at 100℃, repeat three times, collect the supernatant after centrifugation, concentrate, precipitate with ethanol, the volume ratio is supernatant: ethanol=1:5, collect the solid and dry.

[0036] Step 2: Use commercially available glutinous rice starch, add it to deionized water, stir into starch milk with a mass fraction of 20.0% at room temperature, adjust the pH to 12.0 with 0.1 mol / L NaOH solution, and add NaCl (5.0% of the starch mass) to inhibit Starch granules swell; add 1, 6-hexanediol diglycidyl ether (5.0% of starch quality) and tetrabutylammonium bromide (0.7% of starch quality) to the prepared starch milk, and heat to 50 ℃, ...

Embodiment 3

[0043] Step 1: Filter the Flammulina velutipes mycelium filter, wash two to three times with water, collect the precipitate, freeze-dry, and pulverize into powder with a small laboratory pulverizer; add the Flammulina velutipes mycelium powder to distilled water (quality of mycelial solid powder: distilled water Mass=1:50), extract for 2 h in a water bath at 100°C, repeat three times, collect the supernatant after centrifugation, concentrate, and precipitate with ethanol. The volume ratio is supernatant: ethanol=1: 6, collect the solid and dry;

[0044] Step 2: Use commercially available corn starch, add it to deionized water, stir at room temperature into a starch milk with a mass fraction of 10.0%, adjust the pH to 13.0 with 0.1 mol / L NaOH solution, and add NaCl (8.0% of the starch mass) to inhibit Starch granules swell; add 1, 6-hexanediol diglycidyl ether (3.0% of starch quality) and tetrabutylammonium bromide (0.6% of starch quality) to the prepared starch milk, and heat to 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com