A method for separating oil and mud from oily sludge

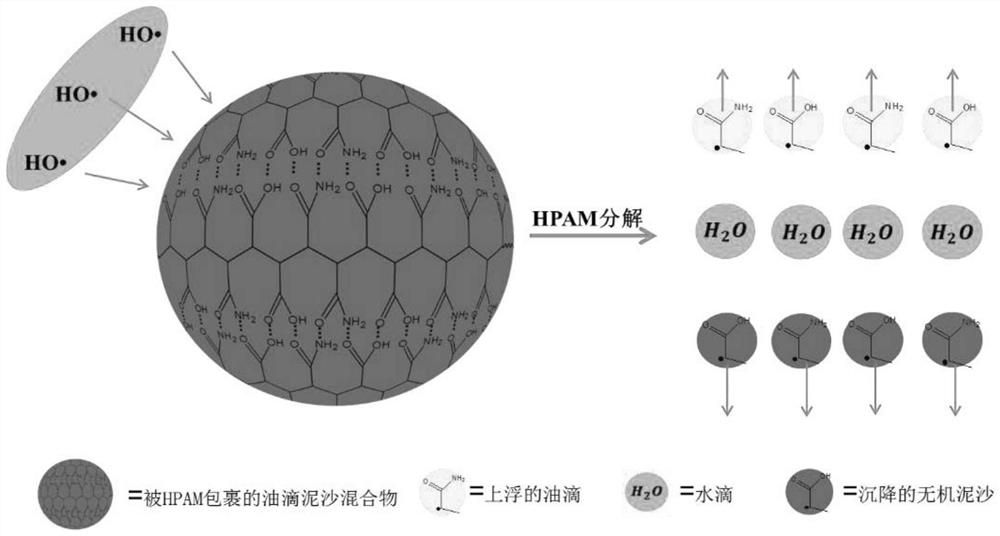

A kind of technology of poly-oil sludge and system, which is applied in the direction of oxidation treatment sludge, mining wastewater treatment, etc., can solve the problems of poly-oil-containing sludge, polymer residue, and inclusion pollutants, etc., achieve low oil content and simplify subsequent steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

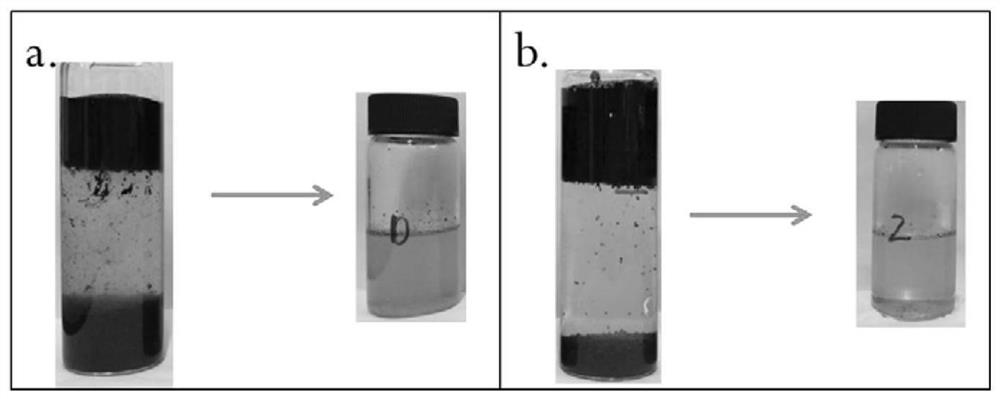

Embodiment 1

[0040] 24mL of thiourea / hydrogen peroxide (mass percentage ratio = 1:1) with a concentration of 1% in mass percentage was reacted with 8g of oily sludge (45°C, 800rpm), stirred for 15min, kept at a constant temperature of 45°C for 15min, and used 10mL Take out the water phase with a syringe and place it in a glass bottle, measure the water phase taken out three times with an oil meter and take the average value to obtain the oil content, which is 20836 mg / L.

Embodiment 2

[0042] 24mL of 3% thiourea / hydrogen peroxide (mass percentage ratio = 1:1) reacted with 8g of oily sludge (45°C, 800rpm), stirred for 15min, kept at a constant temperature of 45°C for 15min, and used 10mL Take out the water phase with a syringe and place it in a glass bottle, measure the water phase taken out three times with an oil meter and take the average value to obtain the oil content, which is 18768mg / L.

Embodiment 3

[0044] 24mL thiourea / hydrogen peroxide (mass percentage ratio = 1:1) with 4% concentration by mass percent was reacted with 8g oily sludge (45°C, 800rpm), stirred for 15min, kept at a constant temperature of 45°C for 15min, and used 10mL Take out the water phase with a syringe and place it in a glass bottle, measure the water phase taken out three times with an oil meter and take the average value to obtain the oil content, which is 28804 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com