Plastic steel coiling pipe processing device

A technology of plastic-steel winding pipe and processing device, which is applied in the field of plastic processing and can solve the problems of not having enough big tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

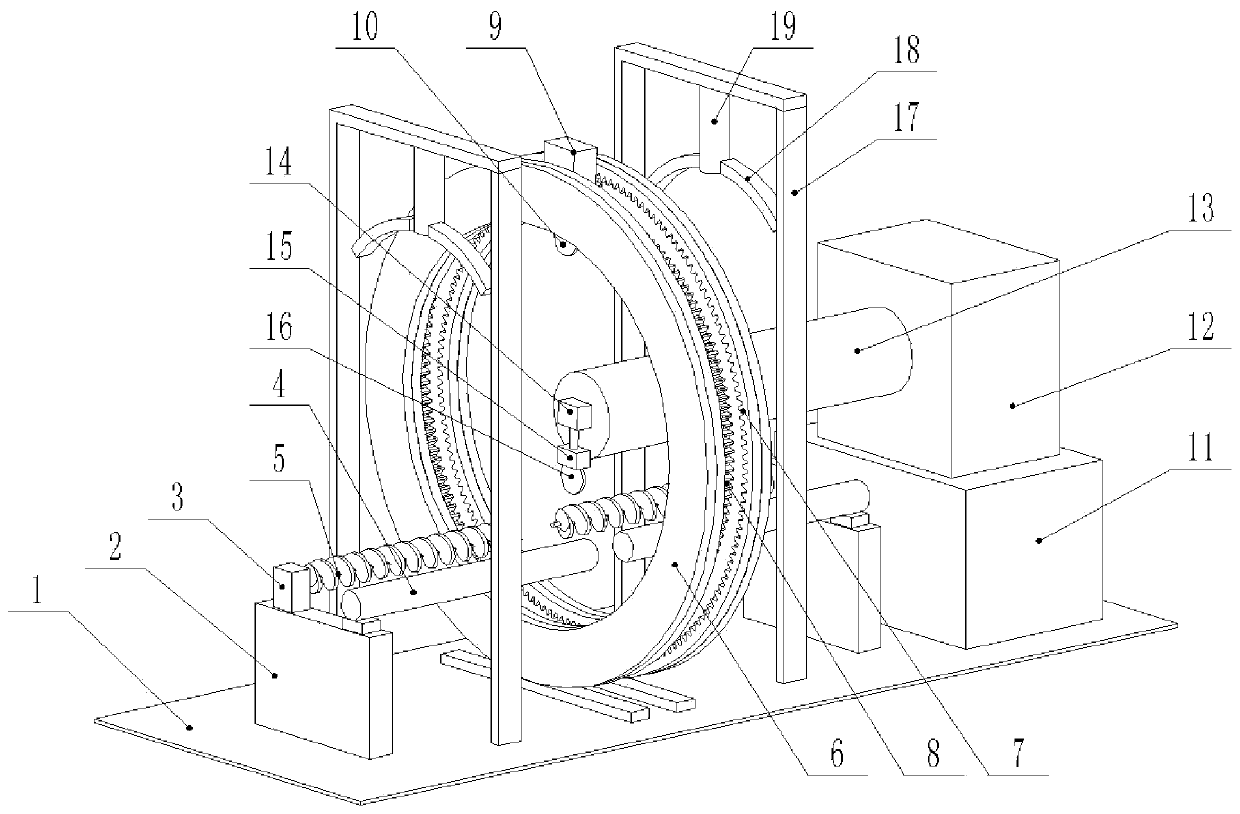

[0021] The reference signs in the accompanying drawings of the specification include:

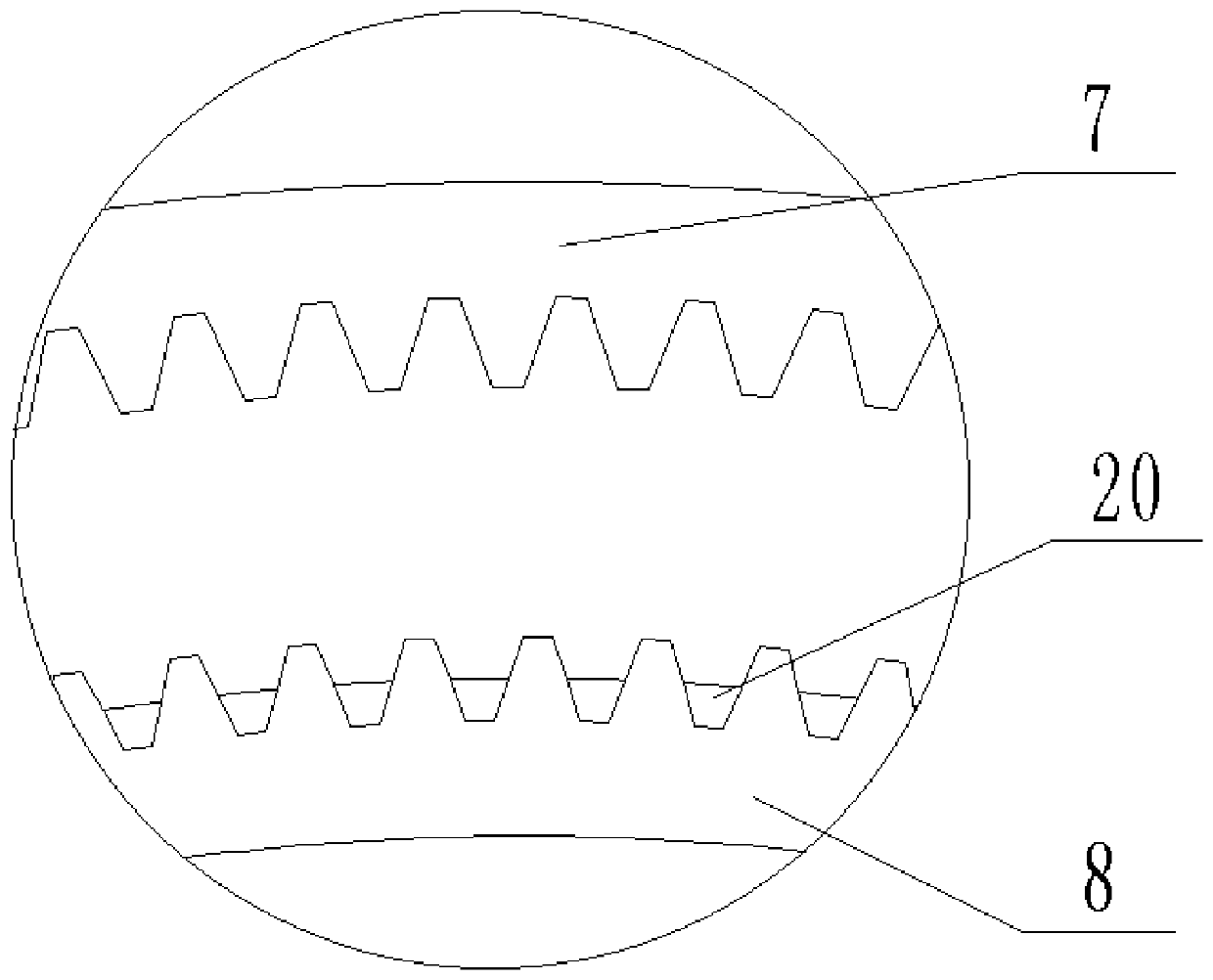

[0022] Frame 1, conveying base 2, conveying motor 3, fixed rod 4, rotating rod 5, annular plate 6, large diameter gear ring 7, small diameter gear gear 8, first sliding seat 9, first cutting knife 10, inner cutting seat 11. Low speed motor 12, inscribed column 13, second cylinder 14, second driving machine 15, second cutting knife 16, frame body 17, pressing plate 18, telescopic rod 19, liquid bag 20.

[0023] The embodiment is basically as attached figure 1 , figure 2 Shown:

[0024] A plastic-steel winding pipe processing device includes a frame 1, a cutting unit, a transport unit and a pressing unit.

[0025] The transportation unit includes two sets of conveyors, the conveyors include a conveying base 2, a conveying motor 3, a fixed rod 4 and a rotating rod 5, the conveying base 2 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com