Preparation method of copper tungstate nanometer fiber photocatalyst

A nanofiber, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the unfavorable preparation, lack of copper tungstate nanofiber materials, etc. problem, to achieve the effect of uniform diameter, wide pore size distribution, and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of copper tungstate nanofiber photocatalyst, the specific steps are as follows:

[0019] 1g WCl 6 Dissolve in 10mL of DMF, stir to dissolve, then add 0.5g of copper acetate, stir to dissolve, add 1g of PAN, stir overnight to obtain the precursor spinning solution; pour the above spinning solution into a 10ml syringe, adjust the spinning process parameters The spinning voltage is 15kV, the injector advance speed is 2mm / h, the receiving distance between the needle and the drum is 10cm, the drum speed is 300r / min, and the room temperature is controlled at 25°C; put the dried composite fiber into the muffle furnace, 600 Calcining at ℃ for 1 hour, the heating rate is controlled at 1 ℃ / min, and cooled to obtain porous copper tungstate nanofibers.

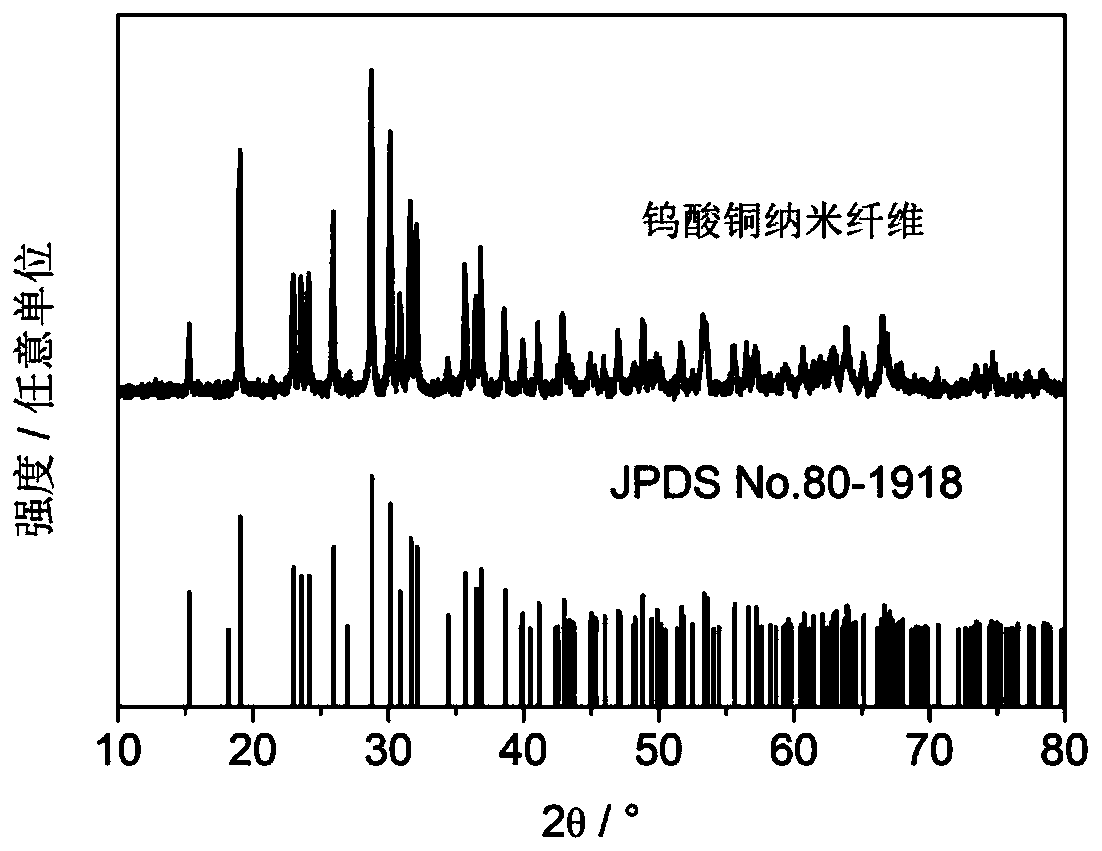

[0020] figure 1 The X-ray diffraction pattern of copper tungstate nanofibers is given. It can be seen from the figure that the crystal form of copper tungstate is well matched to the triclinic system, and the...

Embodiment 2

[0022] A preparation method of copper tungstate nanofiber photocatalyst, the specific steps are as follows:

[0023] 1g WCl 6 Dissolve in 10mL of DMF, stir for 20 minutes, then add 0.5g of copper acetate, stir to dissolve, add 1g of PVP, stir overnight to obtain spinning solution; pour the above spinning solution into a 10ml syringe, adjust spinning process parameters The spinning voltage is 16kV, the injector advance speed is 3mm / h, the receiving distance between the needle and the roller is 10cm, and the roller speed is 350r / min to obtain the composite nanofiber, and the temperature is kept at 120°C for 6h; the dried composite fiber is put into the muffle In the furnace, calcinate at 650°C for 1 hour, control the heating rate at 1°C / min, and cool to obtain porous copper tungstate nanofibers.

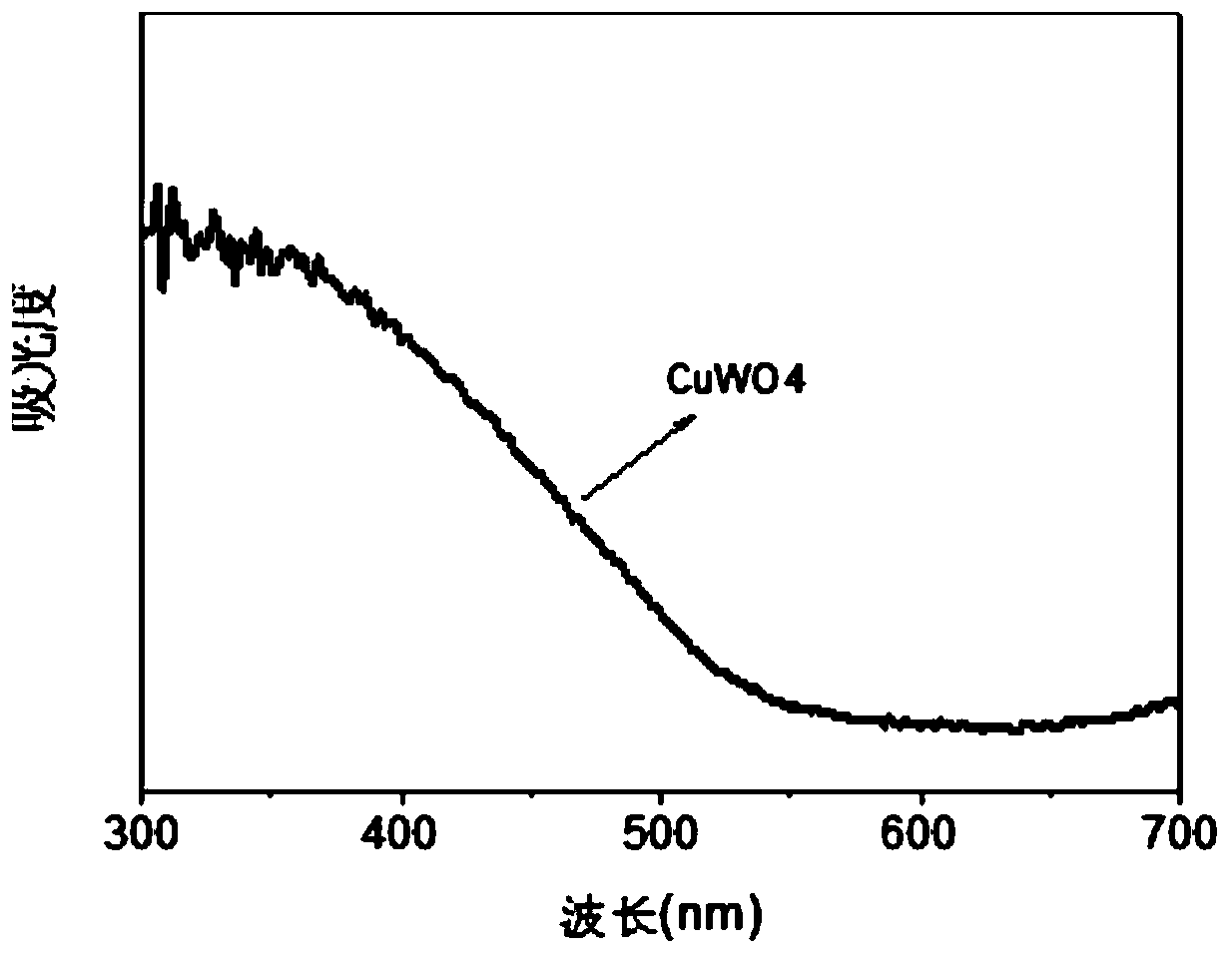

[0024] figure 2 The ultraviolet-visible diffuse reflection spectrum of the prepared copper tungstate nanofibers shows that the absorption of copper tungstate increases sharply below...

Embodiment 3

[0026] A preparation method of copper tungstate nanofiber photocatalyst, the specific steps are as follows:

[0027] Dissolve 0.61g of ammonium tungstate in 12mL of DMF, ultrasonically dissolve, then add 0.44g of copper acetate, stir to dissolve, add 1.5g of PVP, heat to dissolve, stir overnight to obtain spinning solution; pour the above spinning solution into 10ml In the injector, adjust the spinning process parameters as follows: spinning voltage 17kV, injector advance speed 6mm / h, needle and drum receiving distance 10cm, drum speed 380r / min, namely porous nanofibers, 150°C constant temperature 10h; dry The final composite fiber was put into a muffle furnace, calcined at 550°C for 1 hour, the heating rate was controlled at 5°C / min, and cooled to obtain yellow copper tungstate nanoparticles.

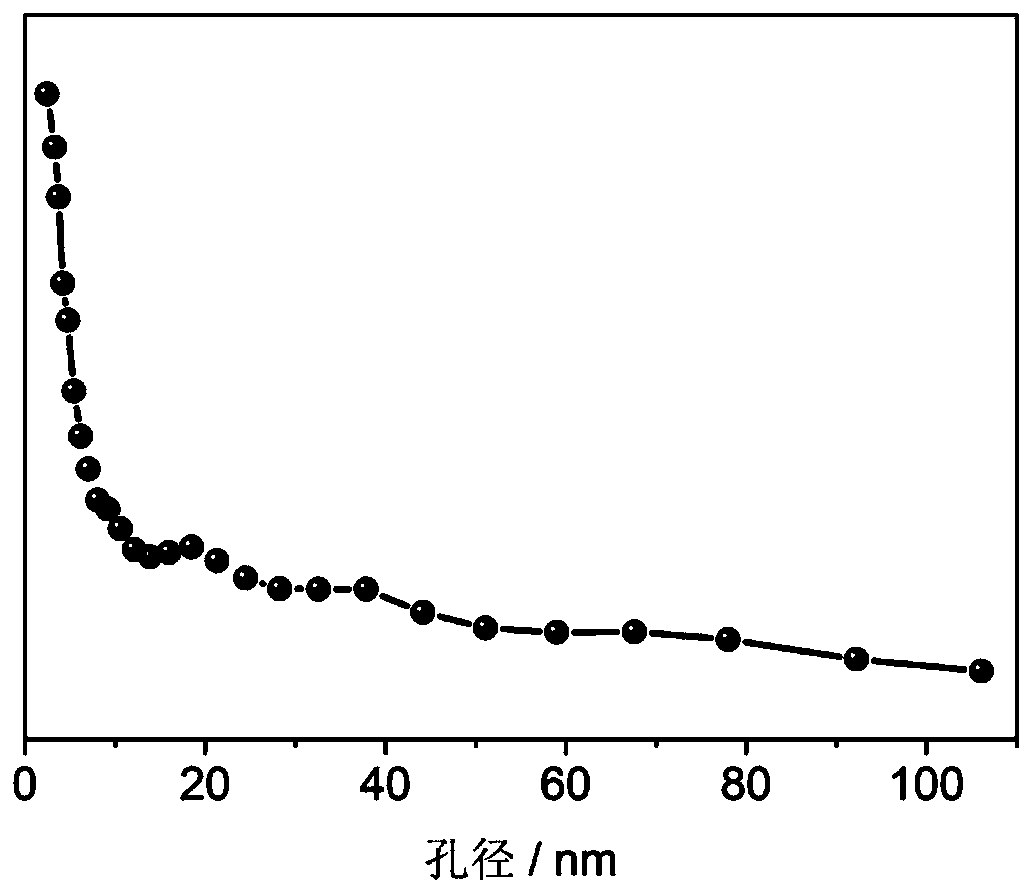

[0028] image 3 It is the pore size distribution diagram of copper tungstate measured by specific surface area and pore analyzer. It can be seen from the figure that the pore size dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com