A device and process for deep oxidation desulfurization and denitrification of industrial flue gas

A deep oxidation, industrial flue gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of difficult recycling of nitrate/nitrite mixture, single, insufficient removal rate of nitrogen oxides, etc. problems, to achieve the effect of improving technical economy, improving removal efficiency, and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

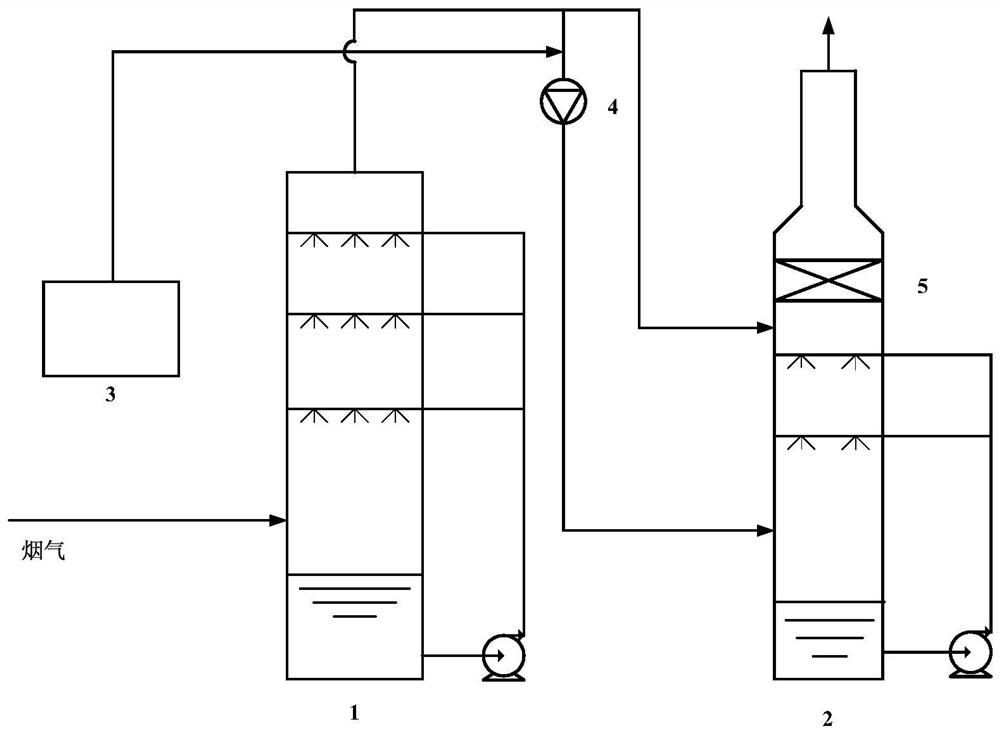

[0033] This embodiment provides a device for deep oxidation desulfurization and denitrification of industrial flue gas. The device includes the first absorption tower 1, the second absorption tower 2, the ozone generator 3, the induced draft fan 4 and the 2 The demister 5 on the top; the outlet pipeline of the first absorption tower 1 is divided into two roads, one road is connected with the bottom of the absorption section of the second absorption tower 2, and an induced draft fan 4 is set on this pipeline, and this pipe Road is connected with the ozone conveying pipe of ozone generator 3; Another road is connected with the top of the second absorption tower 2 absorption sections;

[0034] Using the above device to carry out deep oxidation, desulfurization and denitrification of coke oven flue gas discharged by a coking enterprise, the flue gas flow rate is 10000Nm 3 / h, SO 2 Concentration 500mg / Nm 3 , NO x Concentration 400mg / Nm 3 .

[0035] The specific method is:

[...

Embodiment 2

[0039] Using the oxidative desulfurization and denitrification device provided in Example 1 to carry out deep oxidative desulfurization and denitrification of the coke oven flue gas discharged by a coking enterprise, the flue gas flow rate is 5000Nm 3 / h, SO 2 Concentration 300mg / Nm 3 , NO x Concentration 500mg / Nm 3 .

[0040] The specific method is:

[0041] The above-mentioned flue gas is desulfurized through the first absorption tower 1; the 4000Nm 3 / h of flue gas is drawn out and mixed with ozone from the ozone generator 3, the amount of ozone introduced is 2.87kg / h, and the molar ratio of NO to the total amount of flue gas is 1.1; after the flue gas is mixed with ozone and undergoes deep oxidation, Enter the bottom of the second absorption tower 2 to absorb and remove NOx. The absorbent in this absorption tower is quicklime slurry, and the pH of the absorption reaction is controlled at about 5.0. The remaining 1000Nm 3 / h The flue gas enters the upper part of the ...

Embodiment 3

[0044] The oxidative desulfurization and denitrification device provided in Example 1 is used to carry out deep oxidation desulfurization and denitrification of the sintering flue gas discharged by a certain iron and steel enterprise, and the flue gas flow rate is 20000Nm 3 / h, SO 2 Concentration 2000mg / Nm 3 , NO x Concentration 300mg / Nm 3 .

[0045] The specific method is:

[0046] The above-mentioned flue gas is desulfurized through the first absorption tower 1; the 12000Nm 3 / h of flue gas is drawn out and mixed with ozone from the ozone generator 3, the amount of ozone introduced is 5.95kg / h, and the molar ratio of NO to the total amount of flue gas is 0.95; after the flue gas is mixed with ozone and undergoes deep oxidation, Enter the bottom of the second absorption tower 2 for absorption and removal. The absorbent in this absorption tower is ammonia water, and the pH of the absorption reaction is controlled at about 6.0. The remaining 8000Nm 3 / h The flue gas ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com