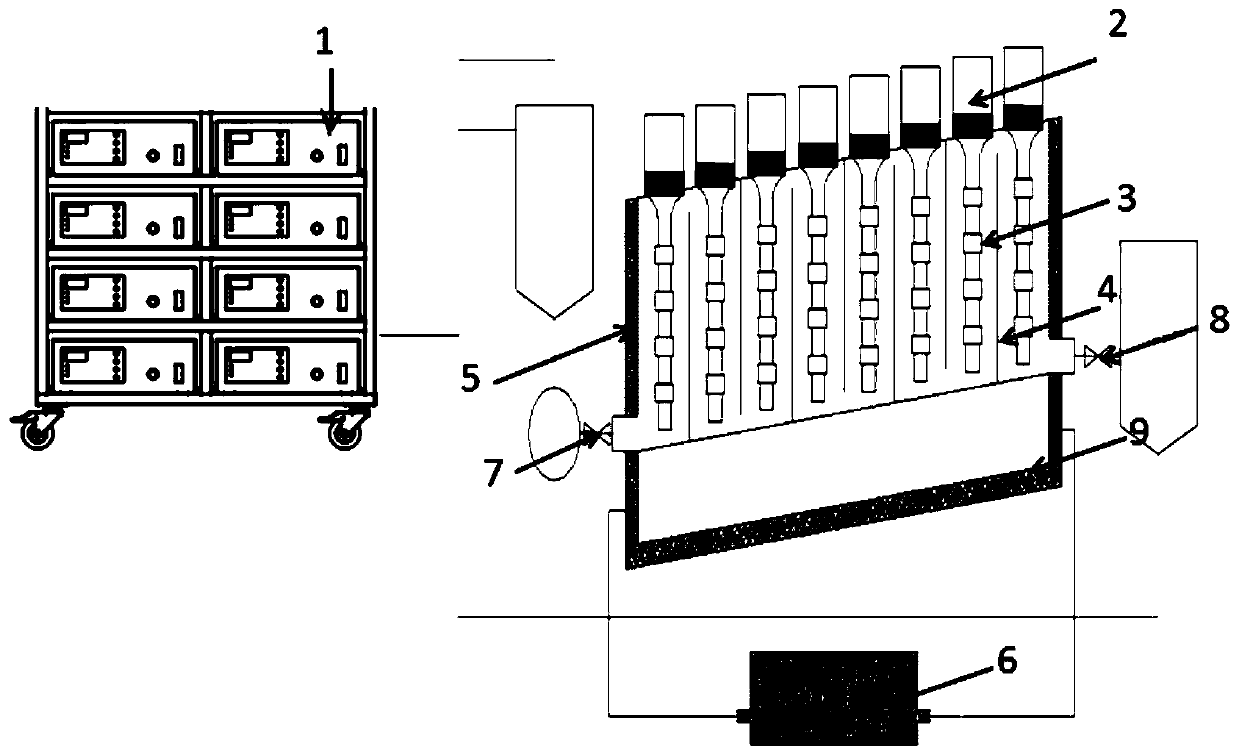

Ultrasonic-thermal compounding continuous sterilization device and method for milk sterilization

A sterilizing device and heat compounding technology, applied in the field of food engineering, can solve problems such as low ultrasonic power intensity, failure to achieve commercial sterility, uneven sound field density, etc., achieve continuous flow operation, maintain original quality properties, and improve Effect of Bactericidal Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

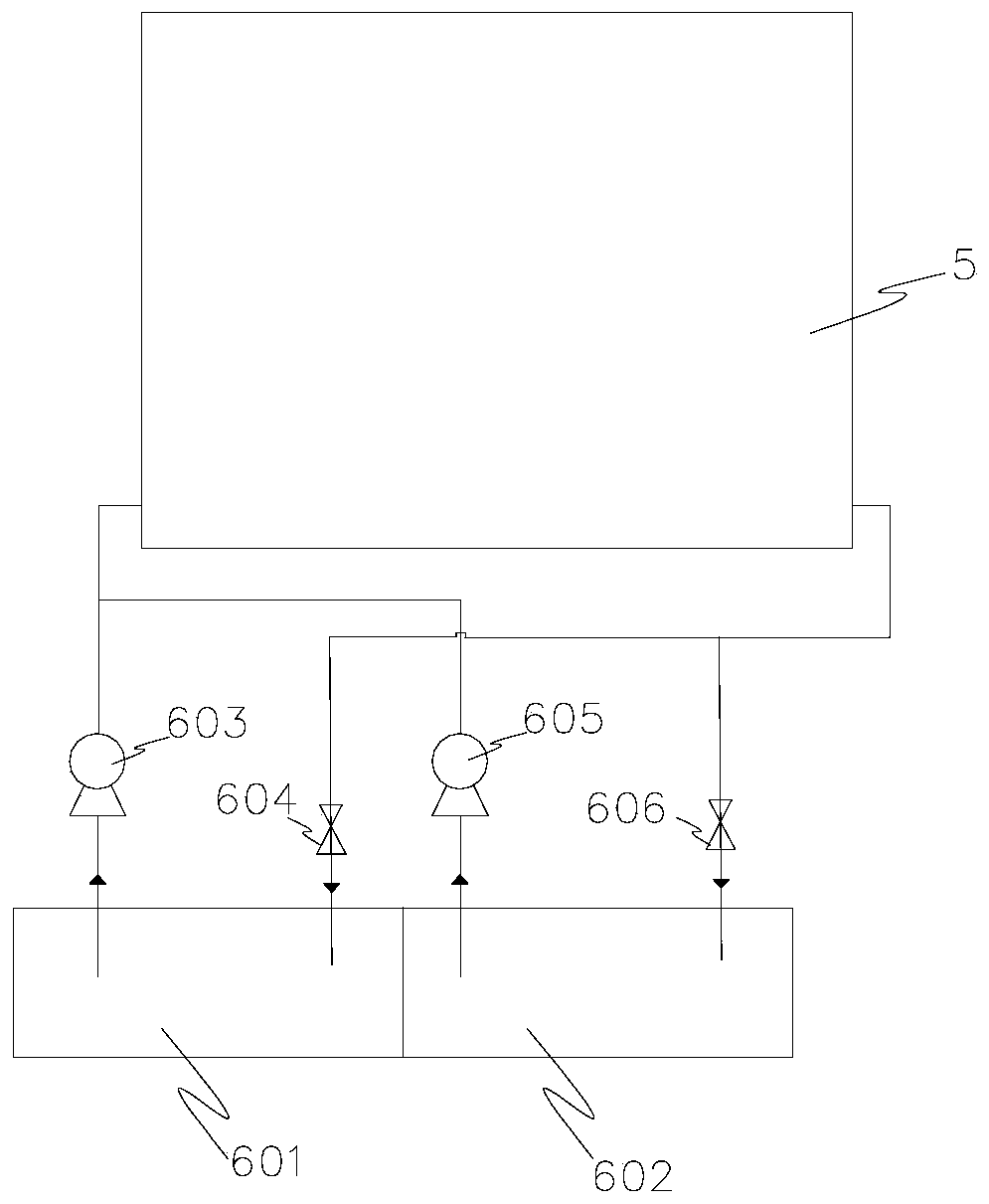

Method used

Image

Examples

Embodiment 1

[0049] One-sound heat compound sterilization technology treatment

[0050] Preparation of milk inoculated with Staphylococcus aureus

[0051] The Staphylococcus aureus standard strain ATCC 25923 was inoculated in ordinary broth medium, and cultured on a shaker at 37°C until the logarithmic growth phase. Use 0.85% (mass percentage) sterile saline to wash the bacteria in the logarithmic growth phase twice, resuspend, so that the concentration of the bacteria is about 109CFU / mL, and then prepare according to the ratio of 1:9 (bacteria liquid: milk) The inoculation volume is 108CFU / mL of milk.

[0052] (2) Acoustic and thermal composite treatment

[0053] Experimental group: The inoculated milk is treated with a new type of sound-thermal composite sterilization device. The specific steps are: put 300mL of milk into a closed treatment chamber, penetrate the multi-node ultrasonic probe into the liquid surface, turn on the cooling water circulation device, turn on the high-power ul...

Embodiment 2

[0065] One heat combined with ultrasonic sterilization technology

[0066] Bacterial suspension preparation

[0067] Same as the method of step (1) in Example 1.

[0068] joint processing

[0069] The method is basically the same as step (2) in Example 1, only the processing power is adjusted to 200W, the processing temperature is 63°C, and the processing time is 7.5min.

[0070] Two detection

[0071] Same as the method of two in embodiment 1.

[0072] The results are as follows: both the control group and the experimental group can reduce the number of Staphylococcus aureus by 5 logarithmic levels, the protein particle size of the control group after pasteurization is 3.4nm, and the protein content is 2.5%. The particle size of the protein in the experimental group was 2.7nm and the protein content was 3.2%. It can be seen that the method of the present invention better maintains the quality and content of the original protein in milk.

[0073] Compared with Example 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com