Measurement method and system for detecting coaxiality by using single laser sensor

A laser sensor and coaxiality measurement technology, applied in the field of measurement systems, can solve problems such as difficult detection, complex structure design of the measurement system, and high cost, and achieve high efficiency, good industrial automation level, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

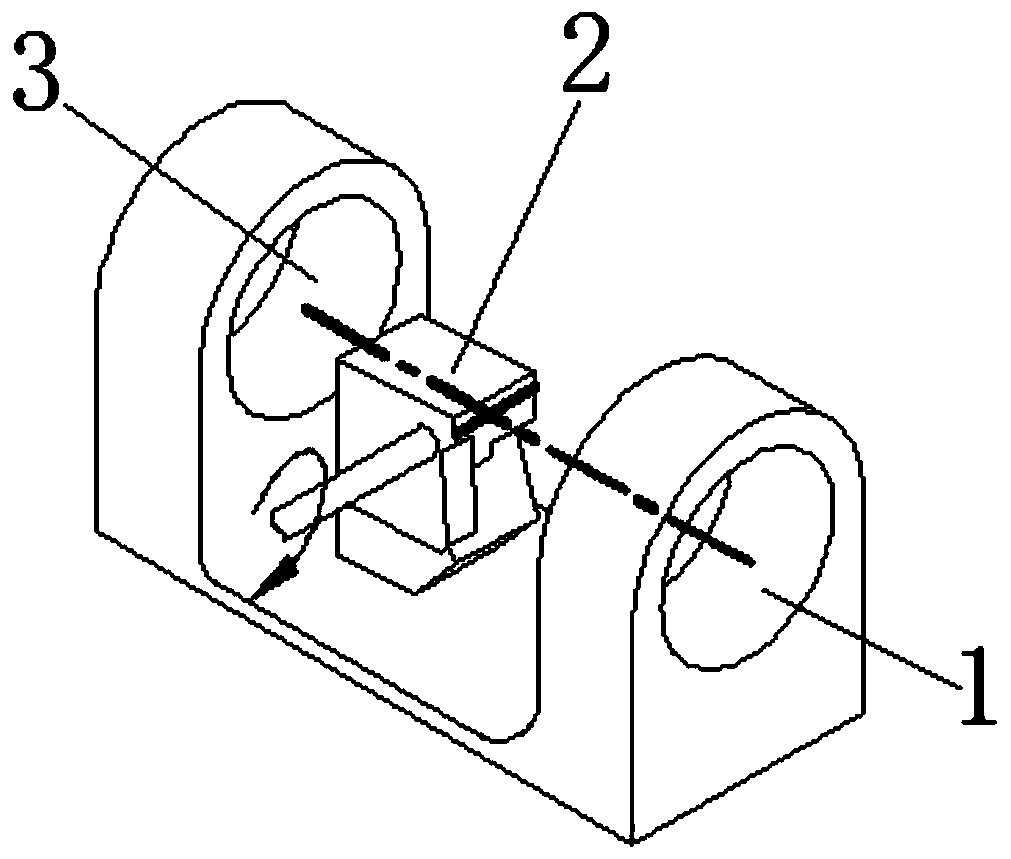

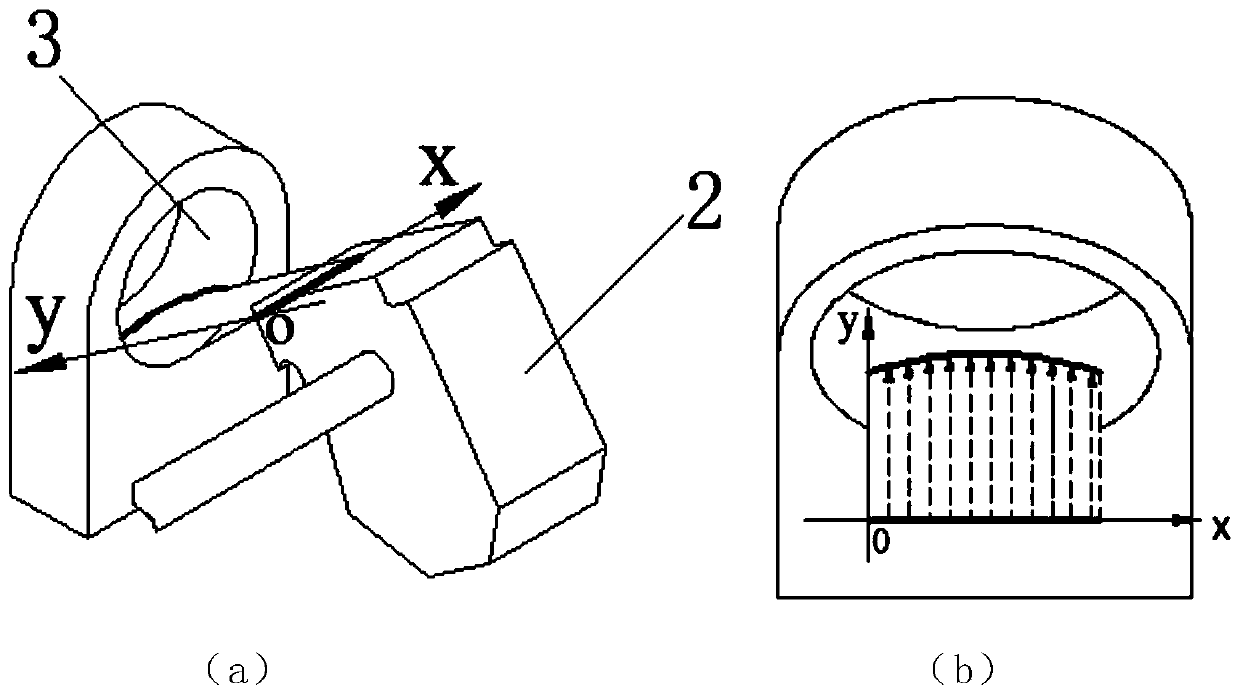

[0038] The invention provides a measurement method and system for detecting coaxiality with a single laser sensor. For holes with continuous surface features processed by drills, milling cutters, etc., the local characteristics are used to reflect the characteristics of the whole. The feature points in the local area of each hole are fitted to the axis, so as to calculate the coaxiality of the two holes to be measured. The invention can realize high-efficiency and high-precision coaxiality detection for unconnected hole pairs with a certain axial distance in parts, and has good industrial automation level and economic efficiency.

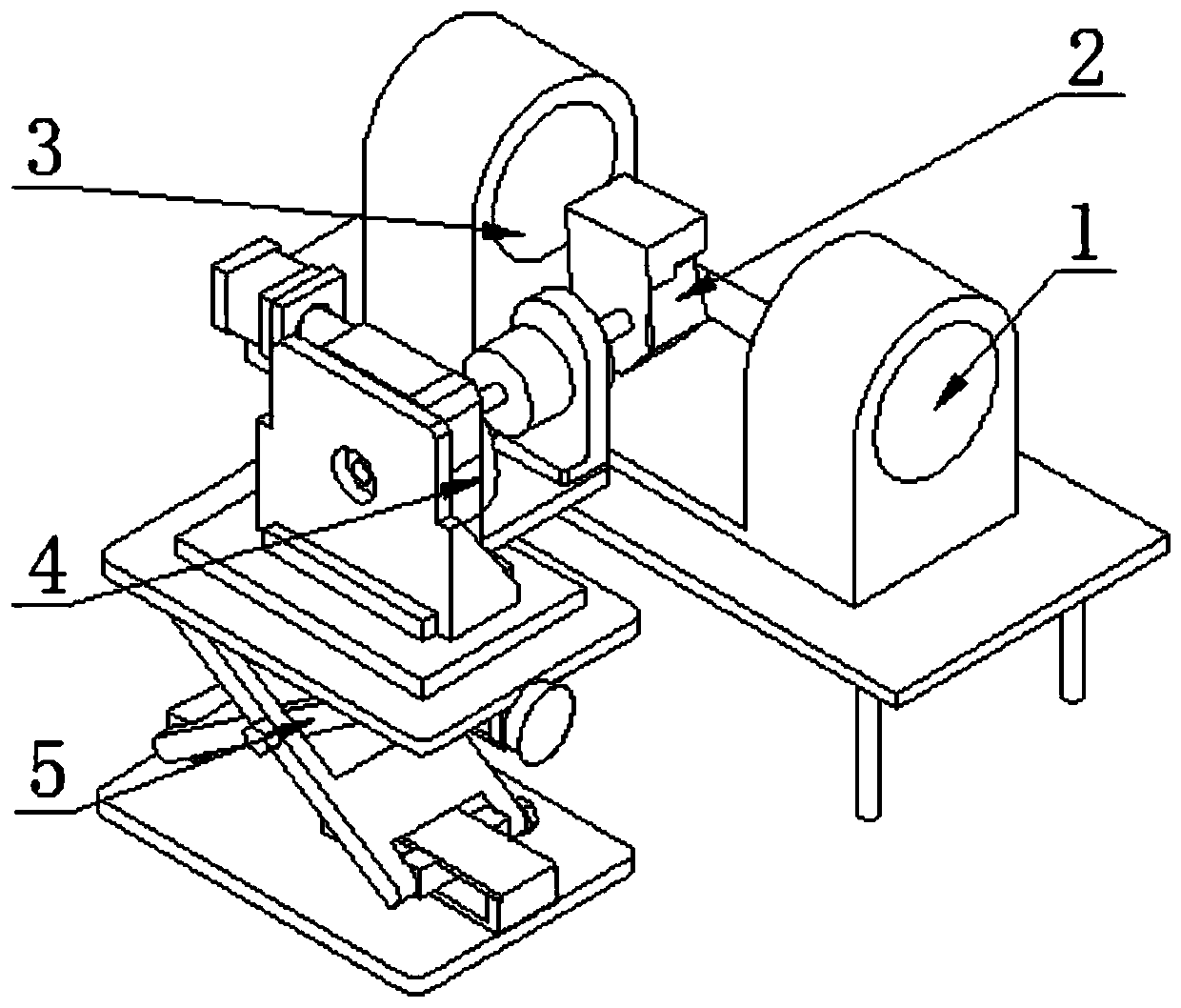

[0039] A measurement system using a single laser sensor to detect coaxiality, including a laser sensor 2, an electric rotary table 4, a motion mechanism 5 and a computer, the electric rotary table 4 is arranged on the motion mechanism 5, and the laser sensor 2 is located between two holes to be measured It is connected with the electric turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com