Simulated projectile speed measuring system for researching cased telescoped ammunition impact extrusion process

A technology for simulating projectiles and simulating signals, which is applied in speed/acceleration/shock measurement, acceleration measurement, ammunition, etc. It can solve the problem that the measurement system cannot provide sufficient protection, the bomb-borne measurement device cannot be built in, and the research difficulty in the process of impact extrusion and other issues to achieve the effect of ensuring subsequent analysis and processing, low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

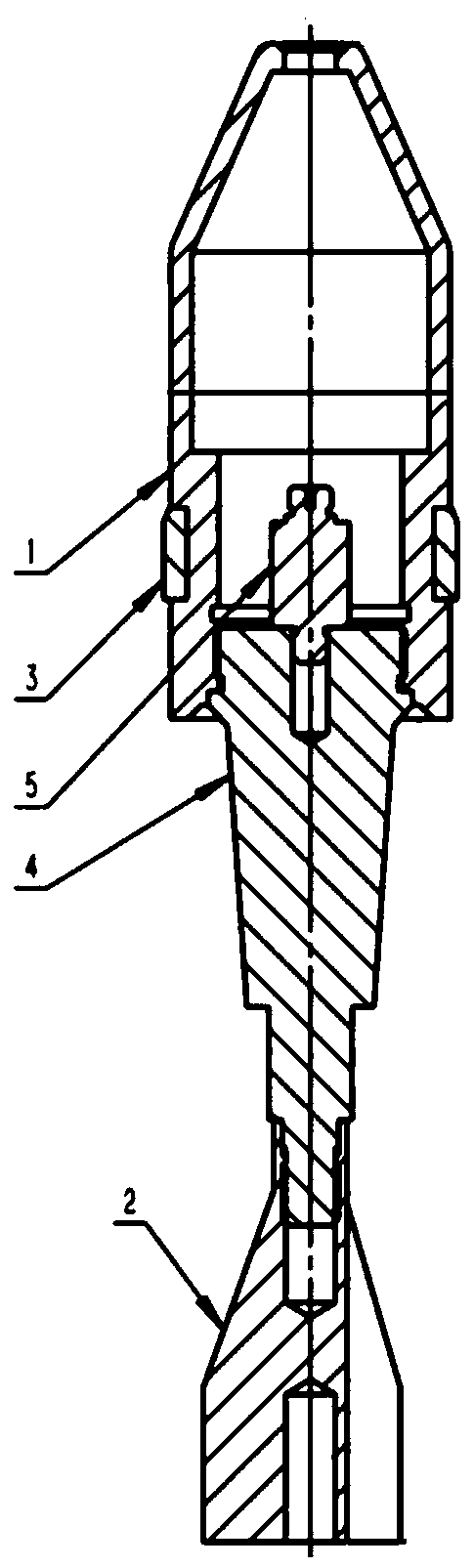

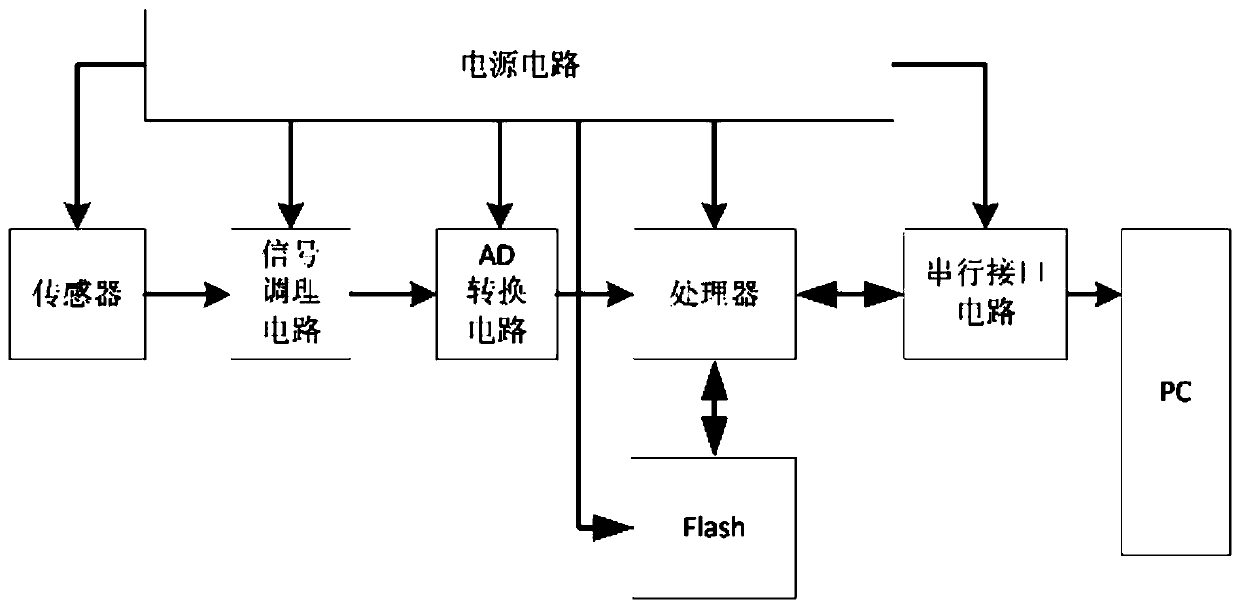

[0032] The present invention is a simulated projectile velocity measurement system for studying the impact extrusion process of a countersunk projectile, comprising a simulated projectile and an acceleration measurement module 5, the simulated projectile is consistent with the shape, size, center of gravity and mass of the countersunk projectile, and is completely equivalent to the countersunk projectile. And the overall structure is optimized, and the acceleration measurement module can be built in and protected to the maximum extent for recycling; after packaging the power supply circuit, acceleration sensor, signal conditioning circuit, processor, Flash and serial interface circuit, the entire The acceleration measurement module is built into the simulated projectile. Finally, the simulated projectile is recycled, and the data is transmitted to the PC for analysis and processing. The speed change curve during the impact extrusion process can be obtained, so as to achieve a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com