Method for improving oil reservoir recovery rate by integration of plugging, regulating and flooding

A recovery factor and oil reservoir technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve problems such as difficulty in propelling oil displacement agents, reducing the microscopic sweep volume of oil displacement agents, clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

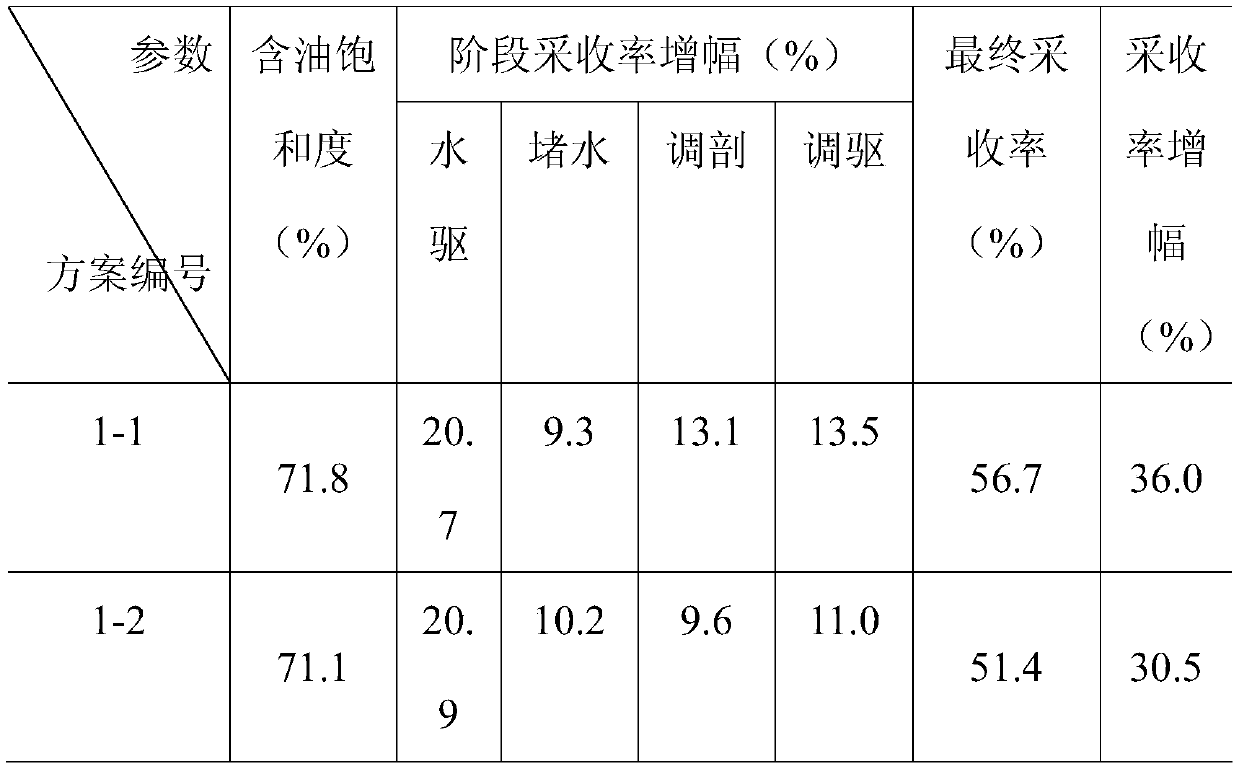

Embodiment 1

[0018] An integrated method of "plugging / adjusting / flooding" to improve oil reservoir recovery, including the following steps:

[0019] Step 1. Prepare a composite gel. The composite gel is prepared by injecting water from the target reservoir. Its composition mass percentage is: 2.5% polyaluminum chloride, 4.5% acrylamide, 0.9% urea, 0.3% ammonium persulfate and 0.3% N ,N-Methylene bisacrylamide, the initial viscosity of the composite gel is less than 5mPa·s, and the viscosity after gelation exceeds 10×10 4 mPa·s;

[0020] Step 2. Prepare the composite system of "polymer microspheres / high-efficiency oil-displacing agent", and prepare the composite system of "polymer microspheres / high-efficiency oil-displacing agent" by injecting water from the target reservoir. The composition of each component is as follows: Hydrophobic associating polymer gel, the concentration of microspheres is 0.3%, the initial particle size of the microspheres is 2.75μm, and the median particle size is 2.00μ...

Embodiment 2

[0024] An integrated method of "plugging / adjusting / flooding" to improve oil reservoir recovery, including the following steps:

[0025] Step 1. Prepare a composite gel. The composite gel is prepared by injecting water from the target reservoir. Its composition mass percentage is: 1.5% polyaluminum chloride, 3.0% acrylamide, 0.6%% urea, 0.2% ammonium persulfate and 0.2%%N,N-methylenebisacrylamide, the initial viscosity of the composite gel is less than 5mPa·s, and the viscosity after gelation is more than 10×10 4 mPa·s;

[0026] Step 2. Prepare the composite system of "polymer microspheres / high-efficiency oil-displacing agent", and prepare the composite system of "polymer microspheres / high-efficiency oil-displacing agent" by injecting water from the target reservoir. The composition of each component is: the material of polymer microspheres is Hydrophobic associating polymer gel, the concentration of microspheres is 0.2%%, the initial particle size of the microspheres is 1.00μm, and...

Embodiment 3

[0030] An integrated method of "plugging / adjusting / flooding" to improve oil reservoir recovery, including the following steps:

[0031] Step 1. Prepare the composite gel. The composite gel is prepared by injecting water from the target reservoir. Its composition mass percentage is: 3.5% polyaluminum chloride, 6.0% acrylamide, 1.2% urea, 0.4% ammonium persulfate and 0.4% N ,N-Methylene bisacrylamide, the initial viscosity of the composite gel is less than 5mPa·s, and the viscosity after gelation exceeds 10×10 4 mPa·s;

[0032] Step 2. Prepare the composite system of "polymer microspheres / high-efficiency oil-displacing agent", and prepare the composite system of "polymer microspheres / high-efficiency oil-displacing agent" by injecting water from the target reservoir. Each component is composed of: Hydrophobic associating polymer gel, the concentration of microspheres is 0.4%, the initial particle size of the microspheres is 4.50μm, and the median particle size is 2.00μm. After hydrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com