Adjustable-color high near infrared reflectivity type composite organic pigment and preparation method thereof

An inorganic pigment and near-infrared technology, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of the adjustment, transition and change of the color of inorganic cold pigments, and achieve a wide range of color adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

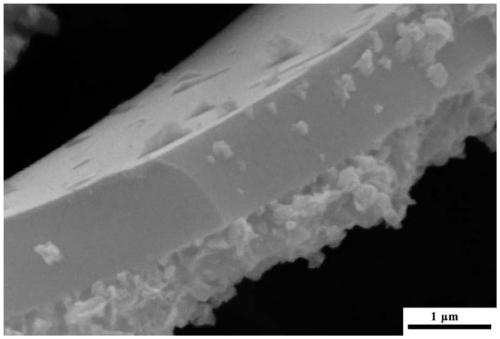

[0061] A kind of preparation method of the high near-infrared reflectance composite inorganic pigment with adjustable color provided by the invention comprises the following steps (refer to image 3 ):

[0062] S1. Weigh the raw material of hollow glass microspheres, add them into NaOH solution under a specific ultrasonic treatment state to carry out surface erosion treatment, and obtain a suspension.

[0063] In the step S1, in terms of mass percentage, the particle gradation of the hollow glass microsphere raw material is: <10 μm accounts for 2-10%, 10-30 μm accounts for 70%, and 30-60 μm accounts for 20-28%; The concentration of the NaOH solution is 1.5-2.75mol / L; the mass volume ratio between the hollow glass microspheres and the NaOH solution is 20-35:1g / L; the ultrasonic amplitude in the ultrasonic treatment state is 20- 80%, the ultrasonic frequency is 20-40KHz, the ultrasonic method is intermittent ultrasonic, stop for 2-4min after ultrasonic for 0-5min, then ultrasoni...

Embodiment 1

[0075] Preparation of high near-infrared reflectance composite inorganic pigment, the composite inorganic pigment is ZnS 0.35 Se 0.65 Coated hollow glass microspheres (Cu / In doping amount is 0), the visual color is light yellow, the optical bandgap energy width is 2.90eV, and the optical absorption edge is 439nm. The preparation method is as follows:

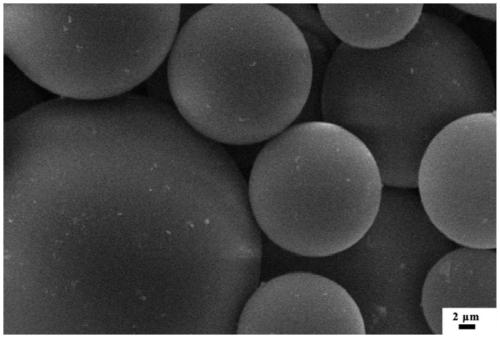

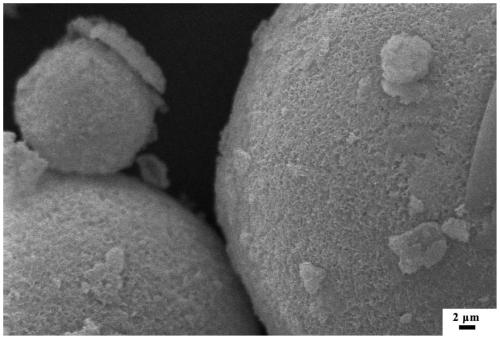

[0076] (1) In terms of mass percentage, the particle gradation is: 0-10 μm accounts for 5%, 10-30 μm accounts for 70%, and 30-60 μm accounts for 25% of the hollow glass microsphere raw material 35g (the hollow glass microsphere Morphological reference of bead raw material under scanning electron microscope Figure 1a ), under the sonochemical treatment reaction conditions that the total ultrasonic power is 1000W, the amplitude is 25%, the ultrasonic frequency is 20KHz, and 5min-2min intermittent ultrasonic (the total ultrasonic time is 17min, 2min is stopped after ultrasonic 5min, and then ultrasonic 5min), Adding to 1L of Na...

Embodiment 2

[0086] Preparation of high near-infrared reflectance composite inorganic pigment, the composite inorganic pigment is ZnS 0.35 Se 0.65 : Cu / In coated hollow glass microspheres, Cu / In is the doping element, the doping method is co-doping, the doping amount is 1.0% (atomic ratio), the visual color is reddish orange, the optical bandgap energy width is 2.59eV, and the optical absorption edge is 524nm. The preparation method is as follows:

[0087] (1) In terms of mass percentage, the particle gradation is: 0-10 μm accounts for 10%, 10-30 μm accounts for 70%, and 30-60 μm accounts for 20% of the hollow glass microsphere raw material 25g (the hollow glass microsphere Morphological reference of bead raw material under scanning electron microscope Figure 1a ), under the sonochemical treatment reaction conditions that the total ultrasonic power is 1000W, the amplitude is 45%, the ultrasonic frequency is 40KHz, and the intermittent ultrasonic is 3min-4min (the total ultrasonic time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com