Substrate composition and substrate prepared therefrom

A composition and substrate technology, applied in the direction of circuit substrate materials, coatings, printed circuit components, etc., can solve the problems of poor mechanical strength, difficult processing, and insufficient rigidity of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

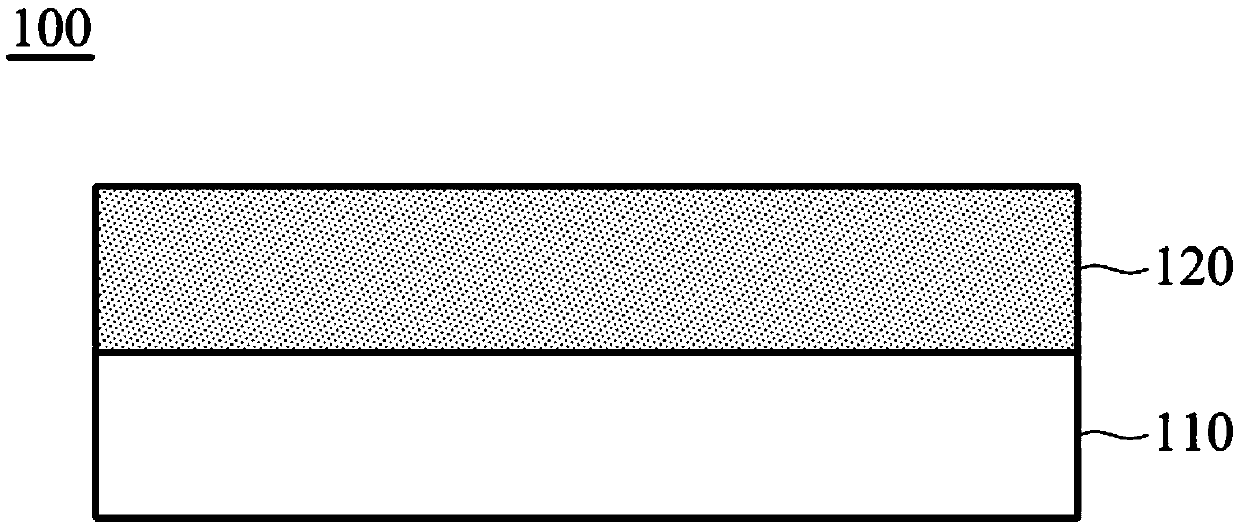

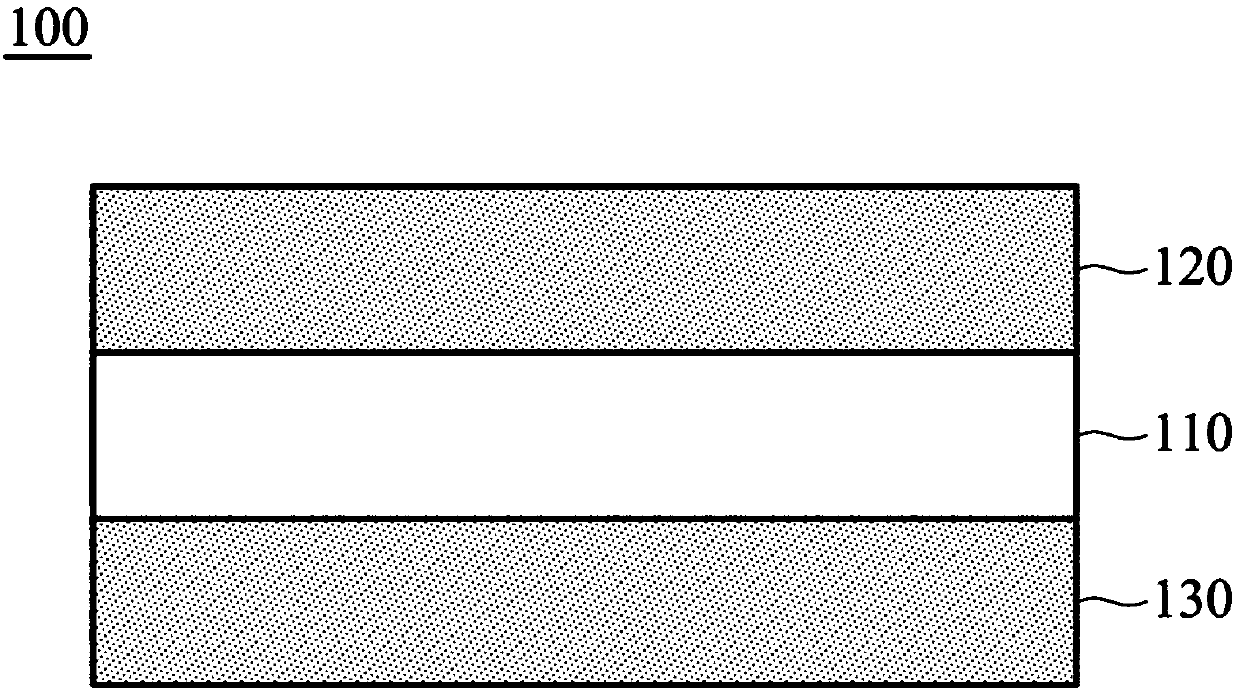

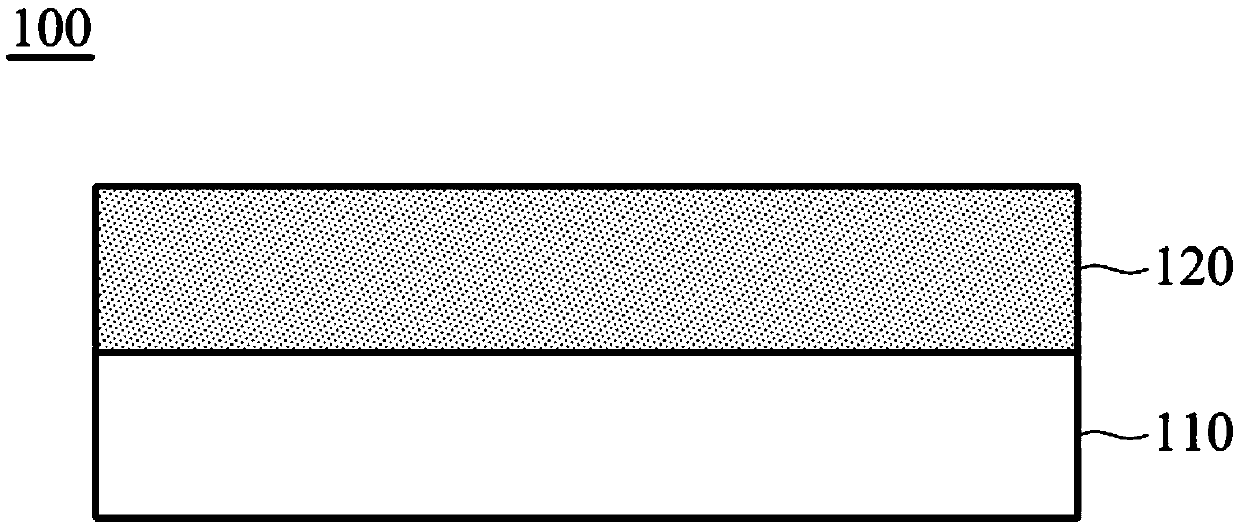

Image

Examples

Embodiment 1

[0034]First, 4 grams of trimethyl isocyanurate (trimethallyl isocyanurate, TMAIC) (purchased from Hunan Farida Technology Co., Ltd.) and 1.2 grams of dicumyl peroxide (dicumylperoxide) were dissolved in 36 gram of methyl ethyl ketone (methyl ethyl ketone), to obtain a solution containing trimethylallyl isocyanurate (TMAIC solution). Next, 27.5 grams of silicon dioxide (average particle diameter of 25 nm, purchased from US Silica), 37.5 grams of polytetrafluoroethylene dispersion (PTFE dispersion) (purchased from DuPont, wherein the PTFE content is 60% (22.5 grams) ), and 0.1 gram of the above-mentioned solution containing trimethylallyl isocyanurate (wherein the content of trimethylallyl isocyanurate is 0.0097 gram) is mixed. After drying to remove part of the solvent, the substrate composition (1) is obtained.

Embodiment 2

[0036] The preparation method of the substrate composition (1) described in Example 1 was carried out, except that the solution containing trimethylallyl isocyanurate was increased from 0.1 g to 0.25 g to obtain the substrate composition (2).

Embodiment 3

[0038] The preparation method of the substrate composition (1) described in Example 1 was carried out, except that the solution containing trimethylallyl isocyanurate was increased from 0.1 g to 0.5 g to obtain the substrate composition (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com